Content Menu

● Introduction

● The Advantages of Aluminum Extrusion Linear Slides

>> Lightweight Yet Strong

>> Corrosion Resistance

>> Thermal Conductivity

>> Easy Customization

● Applications of Aluminum Extrusion Linear Slides

>> Industrial Automation

>> Furniture Design

>> Transportation

>> Medical Equipment

● Comparing Aluminum Extrusion Linear Slides to Alternatives

>> Aluminum vs. Steel

>> Aluminum vs. Plastic

● The Manufacturing Process

● Maintenance and Longevity

● Environmental Considerations

● Cost-Effectiveness

● Design Flexibility

● Future Trends

● Conclusion

● Frequently Asked Questions

>> 1. What are the main advantages of aluminum extrusion linear slides?

>> 2. How do aluminum extrusion linear slides compare to steel alternatives?

>> 3. Are aluminum extrusion linear slides suitable for high-precision applications?

>> 4. What industries benefit most from using aluminum extrusion linear slides?

>> 5. How environmentally friendly are aluminum extrusion linear slides?

● Citations:

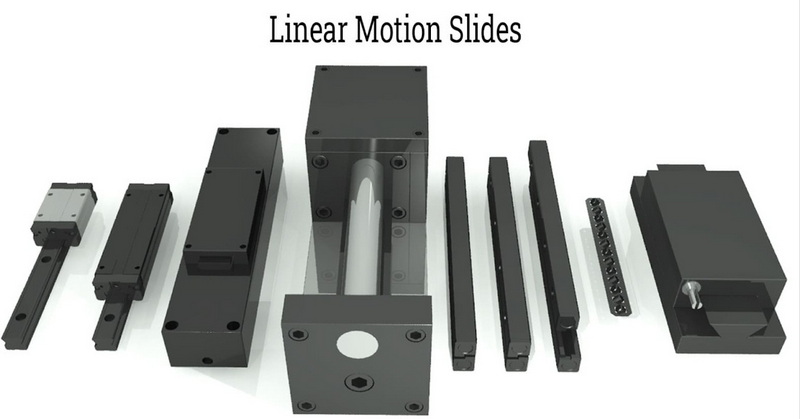

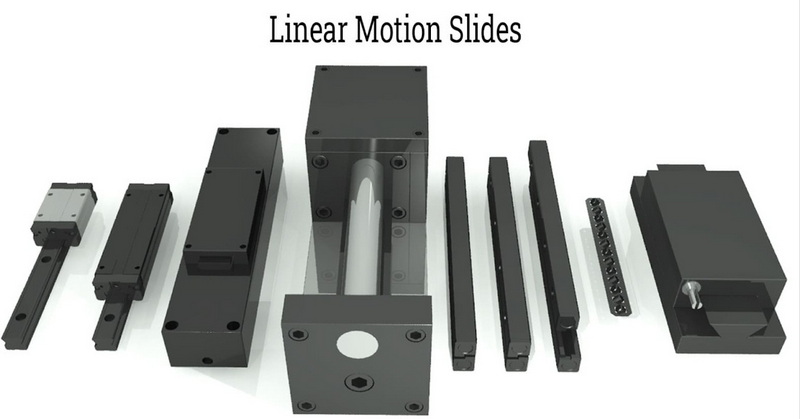

Introduction

In the world of linear motion systems, aluminum extrusion linear slides have emerged as a popular choice for engineers and designers across various industries. These versatile components offer a unique combination of lightweight properties, durability, and cost-effectiveness that make them stand out from other materials. This article will explore the reasons why aluminum extrusion linear slides are often preferred over alternatives and delve into their numerous applications and benefits.

The Advantages of Aluminum Extrusion Linear Slides

Lightweight Yet Strong

One of the primary reasons for choosing aluminum extrusion linear slides is their exceptional strength-to-weight ratio. Aluminum is significantly lighter than steel, making it easier to handle and install. Despite its lightweight nature, aluminum extrusion linear slides can withstand substantial loads and stresses, making them suitable for a wide range of applications.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer when exposed to air, providing excellent corrosion resistance. This property makes aluminum extrusion linear slides ideal for use in environments where moisture or chemical exposure may be a concern.

Thermal Conductivity

Aluminum has high thermal conductivity, which can be advantageous in applications where heat dissipation is crucial. This property helps maintain the stability and performance of linear motion systems in temperature-sensitive environments.

Easy Customization

The extrusion process allows for the creation of complex profiles tailored to specific needs. This flexibility enables designers to create aluminum extrusion linear slides that perfectly fit their application requirements.

Applications of Aluminum Extrusion Linear Slides

Industrial Automation

In the realm of industrial automation, aluminum extrusion linear slides play a crucial role in enhancing efficiency and precision. They are commonly used in:

- Conveyor systems

- Robotic arms

- Automated assembly lines

These applications benefit from the smooth linear motion provided by aluminum extrusion linear slides, reducing friction and wear on components.

Furniture Design

The furniture industry has embraced aluminum extrusion linear slides for their versatility and aesthetic appeal. They are frequently used in:

- Sliding doors

- Adjustable table systems

- Modular storage solutions

The lightweight nature of aluminum allows for larger sliding components that remain easy to operate, enhancing user experience.

Transportation

In the automotive and aerospace industries, weight reduction is a constant goal. Aluminum extrusion linear slides contribute to this by:

- Reducing overall vehicle weight

- Improving fuel efficiency

- Enhancing performance in aircraft components

Aluminum extrusion linear slide in automotive application

Medical Equipment

The medical field benefits from the precision and cleanliness of aluminum extrusion linear slides. They are used in:

- Surgical tables

- Medical imaging equipment

- Laboratory automation systems

The corrosion resistance and ease of sterilization make aluminum an excellent choice for these sensitive applications.

Comparing Aluminum Extrusion Linear Slides to Alternatives

Aluminum vs. Steel

While steel is known for its strength, aluminum extrusion linear slides offer several advantages:

- Lighter weight

- Better corrosion resistance

- Easier machining and customization

Aluminum vs. Plastic

Plastic linear slides may be cheaper initially, but aluminum extrusion linear slides provide:

- Greater durability

- Higher load-bearing capacity

- Better thermal management

The Manufacturing Process

Understanding the manufacturing process of aluminum extrusion linear slides helps appreciate their unique properties:

1. Aluminum billets are heated to near-melting temperatures

2. The heated aluminum is forced through a die to create the desired profile

3. The extruded profile is cooled and cut to length

4. Additional machining and surface treatments may be applied

This process allows for the creation of complex shapes with tight tolerances, ensuring precision in linear motion applications.

Maintenance and Longevity

Aluminum extrusion linear slides require minimal maintenance compared to other materials. Their inherent properties contribute to a long service life:

- Resistance to corrosion reduces the need for protective coatings

- Self-lubricating properties in some designs minimize the need for regular lubrication

- The hardness of anodized aluminum surfaces resists wear and tear

These factors combine to lower the total cost of ownership over the life of the linear motion system.

Environmental Considerations

In an era of increasing environmental awareness, aluminum extrusion linear slides offer several eco-friendly benefits:

- Aluminum is 100% recyclable without loss of properties

- The extrusion process produces minimal waste

- The lightweight nature of aluminum contributes to energy savings in transportation and operation

Cost-Effectiveness

While the initial cost of aluminum extrusion linear slides may be higher than some alternatives, they often prove more cost-effective in the long run due to:

- Reduced maintenance costs

- Longer lifespan

- Energy savings in operation

- Lower shipping costs due to lighter weight

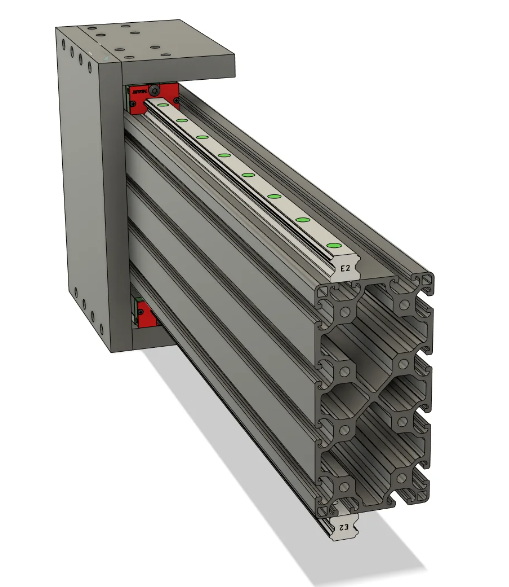

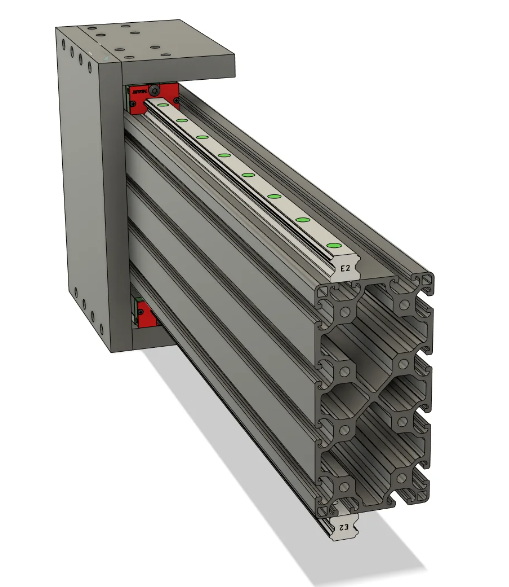

Design Flexibility

The versatility of aluminum extrusion linear slides extends to their design possibilities:

- T-slot profiles allow for easy attachment of accessories

- Modular designs enable quick assembly and reconfiguration

- Custom profiles can be created for unique applications

This flexibility makes aluminum extrusion linear slides adaptable to a wide range of industries and uses.

Future Trends

As technology advances, the future of aluminum extrusion linear slides looks promising:

- Integration with smart sensors for predictive maintenance

- Development of new aluminum alloys for even better performance

- Increased use in emerging industries like renewable energy and space exploration

These trends suggest that aluminum extrusion linear slides will continue to play a crucial role in linear motion systems for years to come.

Conclusion

Aluminum extrusion linear slides offer a compelling combination of benefits that make them an excellent choice for a wide range of applications. Their lightweight yet strong nature, corrosion resistance, and design flexibility provide advantages over other materials in many scenarios. As industries continue to demand more efficient and precise linear motion solutions, aluminum extrusion linear slides are well-positioned to meet these needs.

The versatility, cost-effectiveness, and environmental benefits of aluminum extrusion linear slides make them a smart choice for engineers and designers looking to optimize their linear motion systems. Whether in industrial automation, furniture design, transportation, or medical equipment, these components prove their worth time and again.

As we look to the future, the continued development of aluminum extrusion technology promises even greater possibilities for linear motion applications. The adaptability and inherent properties of aluminum extrusion linear slides ensure their relevance in an ever-evolving technological landscape.

Frequently Asked Questions

1. What are the main advantages of aluminum extrusion linear slides?

Aluminum extrusion linear slides offer several key advantages:

- Lightweight yet strong construction

- Excellent corrosion resistance

- High thermal conductivity for heat dissipation

- Easy customization through the extrusion process

- Cost-effectiveness over the long term

2. How do aluminum extrusion linear slides compare to steel alternatives?

While steel is known for its strength, aluminum extrusion linear slides offer:

- Significantly lighter weight, making them easier to handle and install

- Better corrosion resistance without the need for additional treatments

- Easier machining and customization options

- Often lower overall costs when considering long-term maintenance and operation

3. Are aluminum extrusion linear slides suitable for high-precision applications?

Yes, aluminum extrusion linear slides can be suitable for high-precision applications:

- The extrusion process allows for tight tolerances in profile creation

- Additional machining can further enhance precision

- When properly designed and implemented, they can provide accurate and repeatable linear motion

- For ultra-high precision needs, hybrid systems combining aluminum extrusions with precision steel components are sometimes used

4. What industries benefit most from using aluminum extrusion linear slides?

Several industries benefit significantly from aluminum extrusion linear slides:

- Industrial automation for conveyor systems and robotic applications

- Furniture design for sliding doors and adjustable components

- Transportation, including automotive and aerospace, for weight reduction

- Medical equipment for precise and clean linear motion solutions

- Renewable energy for solar panel tracking systems

5. How environmentally friendly are aluminum extrusion linear slides?

Aluminum extrusion linear slides are considered environmentally friendly for several reasons:

- Aluminum is 100% recyclable without loss of properties

- The extrusion process produces minimal waste compared to other manufacturing methods

- The lightweight nature of aluminum contributes to energy savings in transportation and operation of equipment

- Aluminum's durability leads to longer product lifecycles, reducing the need for frequent replacements

Citations:

[1] https://toolbox.igus.com/4920/why-are-there-color-variations-between-extruded-aluminum-linear-rails-and-shafting

[2] https://pbclinear.com/product-features/integral-v-technology

[3] https://www.reddit.com/r/hobbycnc/comments/usam20/steel_rod_linear_bearings_vs_aluminum_profile/

[4] https://www.imakerstore.com/linear-rails-extrusions

[5] https://www.youtube.com/watch?v=mbSP4dkfD2g

[6] https://www.reddit.com/r/hobbycnc/comments/1cl4jz0/aluminum_extrusion_with_linear_guide_rail_support/

[7] https://www.eztube.com/understanding-linear-rail-extrusions/

[8] https://www.linearmotiontips.com/what-to-consider-when-specifying-a-customized-linear-slide/

[9] https://www.cnczone.com/forums/t-slot-cnc-building/333872-cnc-posts.html

[10] https://www.yjing-extrusion.com/how-do-modular-aluminum-slides-enhance-linear-motion-systems.html