Content Menu

● Understanding Aluminum Extrusion Linear Bearings

● Advantages of Aluminum Extrusion Linear Bearings

>> 1. Modularity and Flexibility

>> 2. Lightweight Construction

>> 3. Corrosion Resistance

>> 4. Cost-Effectiveness

>> 5. Thermal Management

● Applications of Aluminum Extrusion Linear Bearings

>> 3D Printers and CNC Machines

>> Medical Equipment

● Comparing Aluminum Extrusion Linear Bearings to Traditional Bearings

● Design Considerations for Aluminum Extrusion Linear Bearings

● Maintenance and Longevity

● Future Trends in Aluminum Extrusion Linear Bearings

● Conclusion

● Frequently Asked Questions

>> 1. What are the main advantages of aluminum extrusion linear bearings over traditional bearings?

>> 2. In which industries are aluminum extrusion linear bearings commonly used?

>> 3. How do aluminum extrusion linear bearings contribute to improved system performance?

>> 4. What maintenance is required for aluminum extrusion linear bearings?

>> 5. How do environmental factors affect the performance of aluminum extrusion linear bearings?

● Citations:

In the world of linear motion systems, aluminum extrusion linear bearings have emerged as a game-changing alternative to traditional bearings. These innovative components offer a unique combination of versatility, efficiency, and cost-effectiveness that makes them increasingly popular across various industries. This article will explore the advantages of aluminum extrusion linear bearings and why they are often the preferred choice for many applications.

Understanding Aluminum Extrusion Linear Bearings

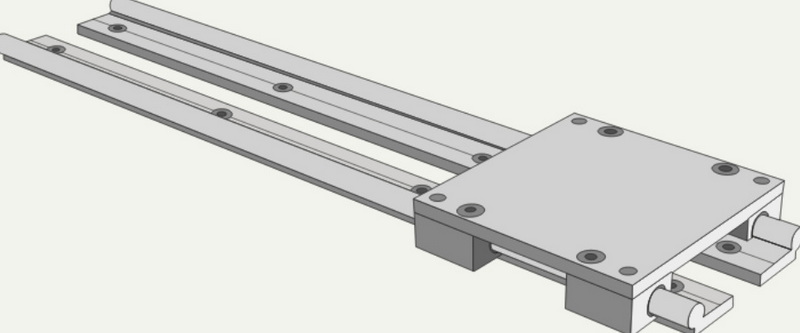

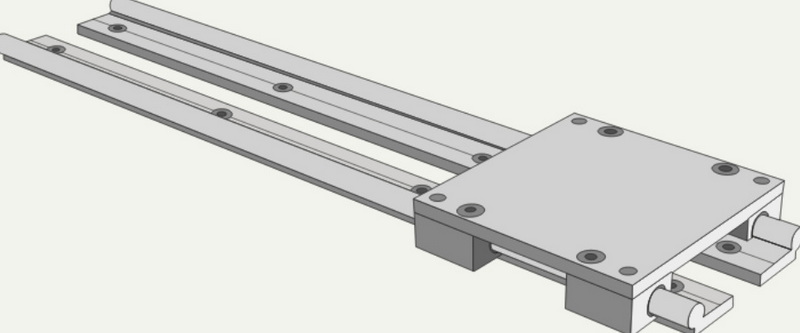

Aluminum extrusion linear bearings are a type of linear motion system that operates within the framework of T-slot modular framing. These bearings are designed to work with extruded aluminum profiles, providing smooth and precise linear motion along a predetermined path.

The core components of an aluminum extrusion linear bearing system include:

1. Extruded aluminum profile with T-slots

2. Linear bearings or wheels

3. Mounting brackets or carriages

These components work together to create a robust and flexible linear motion solution that can be easily customized to meet specific application requirements.

Advantages of Aluminum Extrusion Linear Bearings

1. Modularity and Flexibility

One of the most significant advantages of aluminum extrusion linear bearings is their modularity. The T-slot design of the aluminum profiles allows for easy attachment and reconfiguration of components, making it simple to modify or expand the system as needed.

This flexibility is particularly valuable in industries where rapid prototyping or frequent changes to production lines are common. Engineers can quickly adapt the linear motion system to new requirements without the need for extensive redesign or replacement of the entire setup.

2. Lightweight Construction

Aluminum extrusion linear bearings are significantly lighter than their steel counterparts. This lightweight nature offers several benefits:

- Reduced overall system weight

- Lower inertia, allowing for faster acceleration and deceleration

- Easier handling and installation

- Reduced energy consumption in dynamic applications

The lightweight construction of aluminum extrusion linear bearings makes them ideal for applications where weight is a critical factor, such as in aerospace or mobile robotics.

3. Corrosion Resistance

Aluminum naturally forms a protective oxide layer when exposed to air, making it highly resistant to corrosion. This inherent corrosion resistance is further enhanced in aluminum extrusion linear bearings through anodization, a process that creates a harder, more durable surface.

The corrosion-resistant properties of aluminum extrusion linear bearings make them suitable for use in harsh environments or applications where exposure to moisture or chemicals is a concern.

4. Cost-Effectiveness

Aluminum extrusion linear bearings often prove to be more cost-effective than traditional bearing systems for several reasons:

- Lower material costs compared to steel

- Reduced machining requirements

- Easier installation and maintenance

- Longer lifespan due to corrosion resistance

These factors contribute to a lower total cost of ownership over the life of the linear motion system.

5. Thermal Management

Aluminum has excellent thermal conductivity properties, which can be advantageous in linear motion applications. The ability of aluminum extrusion linear bearings to dissipate heat effectively helps to:

- Reduce thermal expansion and contraction

- Maintain consistent performance in varying temperature conditions

- Extend the lifespan of the bearing components

This thermal management capability is particularly valuable in high-speed or high-load applications where heat buildup can be a concern.

Applications of Aluminum Extrusion Linear Bearings

Aluminum extrusion linear bearings find use in a wide range of industries and applications, including:

1. Automation and Robotics

2. Packaging Machinery

3. 3D Printers and CNC Machines

4. Medical Equipment

5. Automotive Manufacturing

6. Aerospace Industry

7. Food Processing Equipment

Let's explore some of these applications in more detail.

3D Printers and CNC Machines

The lightweight nature and precise motion of aluminum extrusion linear bearings make them ideal for use in 3D printers and CNC machines. These applications require smooth, accurate movement to produce high-quality parts and components.

In 3D printers, aluminum extrusion linear bearings are often used for the X, Y, and Z axes, providing the necessary precision for accurate layer deposition.

Medical Equipment

The cleanliness and corrosion resistance of aluminum extrusion linear bearings make them suitable for use in medical equipment. They can be found in applications such as:

- Patient positioning systems

- Medical imaging equipment

- Laboratory automation

The ability to easily clean and sterilize aluminum components is a significant advantage in medical settings where hygiene is critical.

Comparing Aluminum Extrusion Linear Bearings to Traditional Bearings

To better understand the advantages of aluminum extrusion linear bearings, let's compare them to traditional linear bearing systems:

| Feature | Aluminum Extrusion Linear Bearings | Traditional Linear Bearings |

| Weight | Lightweight | Heavier (especially steel) |

| Modularity | Highly modular | Limited modularity |

| Corrosion Resistance | Excellent | Varies (depends on material) |

| Cost | Generally lower | Often higher |

| Thermal Management | Good heat dissipation | Limited heat dissipation |

| Customization | Easily customizable | Less flexible |

| Installation | Simple, often tool-less | May require specialized tools |

As the table illustrates, aluminum extrusion linear bearings offer several advantages over traditional bearing systems in terms of weight, modularity, and ease of use.

Design Considerations for Aluminum Extrusion Linear Bearings

When incorporating aluminum extrusion linear bearings into a design, several factors should be considered:

1. Load capacity and direction

2. Speed and acceleration requirements

3. Environmental conditions (temperature, humidity, contaminants)

4. Required precision and accuracy

5. Available space and mounting options

By carefully evaluating these factors, engineers can select the most appropriate aluminum extrusion linear bearing configuration for their specific application.

Maintenance and Longevity

One of the key benefits of aluminum extrusion linear bearings is their low maintenance requirements. The self-lubricating properties of many linear bearing designs, combined with the corrosion resistance of aluminum, contribute to a long operational life with minimal upkeep.

To ensure optimal performance and longevity of aluminum extrusion linear bearings:

- Regularly inspect for signs of wear or damage

- Keep the system clean and free from debris

- Follow manufacturer guidelines for lubrication (if required)

- Periodically check and adjust alignment

By following these simple maintenance practices, users can extend the life of their aluminum extrusion linear bearing systems and maintain consistent performance over time.

Future Trends in Aluminum Extrusion Linear Bearings

As technology continues to advance, we can expect to see further innovations in aluminum extrusion linear bearings. Some potential future trends include:

1. Integration of smart sensors for condition monitoring

2. Development of new aluminum alloys with enhanced properties

3. Improved manufacturing techniques for even greater precision

4. Increased use of composite materials in conjunction with aluminum extrusions

These advancements will likely lead to even more efficient and capable linear motion systems, further expanding the applications for aluminum extrusion linear bearings.

Conclusion

Aluminum extrusion linear bearings offer a compelling alternative to traditional bearing systems in many applications. Their unique combination of lightweight construction, modularity, corrosion resistance, and cost-effectiveness makes them an attractive choice for engineers and designers across various industries.

As we've explored in this article, the advantages of aluminum extrusion linear bearings extend beyond their physical properties. The flexibility and ease of use they provide can lead to faster development cycles, reduced maintenance costs, and improved overall system performance.

While traditional bearings still have their place in certain high-load or extreme-precision applications, the versatility and efficiency of aluminum extrusion linear bearings make them a strong contender in the world of linear motion systems.

As technology continues to evolve, we can expect to see further innovations in aluminum extrusion linear bearings, expanding their capabilities and opening up new possibilities for their use in various industries.

Frequently Asked Questions

1. What are the main advantages of aluminum extrusion linear bearings over traditional bearings?

Aluminum extrusion linear bearings offer several advantages over traditional bearings, including:

- Lightweight construction, reducing overall system weight

- High modularity and flexibility for easy customization

- Excellent corrosion resistance

- Cost-effectiveness due to lower material and maintenance costs

- Better thermal management properties

2. In which industries are aluminum extrusion linear bearings commonly used?

Aluminum extrusion linear bearings find applications in various industries, including:

- Automation and robotics

- 3D printing and CNC machining

- Medical equipment manufacturing

- Packaging machinery

- Automotive and aerospace industries

- Food processing equipment

3. How do aluminum extrusion linear bearings contribute to improved system performance?

Aluminum extrusion linear bearings contribute to improved system performance through:

- Reduced inertia, allowing for faster acceleration and deceleration

- Smooth and precise linear motion

- Efficient heat dissipation, maintaining consistent performance

- Easy integration and reconfiguration for optimized designs

- Low maintenance requirements, reducing downtime

4. What maintenance is required for aluminum extrusion linear bearings?

Maintenance for aluminum extrusion linear bearings is generally minimal and includes:

- Regular inspection for signs of wear or damage

- Keeping the system clean and free from debris

- Following manufacturer guidelines for lubrication (if required)

- Periodic checking and adjustment of alignment

- Replacing worn components as needed

5. How do environmental factors affect the performance of aluminum extrusion linear bearings?

Environmental factors can impact the performance of aluminum extrusion linear bearings in the following ways:

- Temperature: Aluminum's thermal properties help maintain consistent performance across varying temperatures

- Humidity: The corrosion resistance of aluminum makes these bearings suitable for use in humid environments

- Contaminants: While resistant to many contaminants, proper sealing may be necessary in extremely dirty or chemically harsh environments

- UV exposure: Anodized aluminum extrusions offer good resistance to UV degradation

- Vibration: The lightweight nature of aluminum can help reduce vibration in some applications

Citations:

[1] https://8020.net/blog/a-guide-to-8020-t-slot-linear-bearings.html

[2] https://inquivixtech.com/aluminum-extrusion-process/

[3] https://stock.adobe.com/search?k=linear+bearings

[4] https://www.reddit.com/r/hobbycnc/comments/usam20/steel_rod_linear_bearings_vs_aluminum_profile/

[5] https://www.linkedin.com/pulse/linear-bearing-design-guide-lily-bearing-manufacturing-g8aic

[6] https://www.youtube.com/watch?v=vHz541yufME

[7] https://toolbox.igus.com/4920/why-are-there-color-variations-between-extruded-aluminum-linear-rails-and-shafting

[8] https://www.nskautomation.com/linear-bearing-rails/

[9] https://www.youtube.com/watch?v=_ajfmUNBVjo