Content Menu

● Understanding Aluminum Extrusion

● Key Advantages of Aluminum Extrusion Housing

● Applications of Aluminum Extrusion Housing

● Comparison with Other Materials

● Additional Benefits of Aluminum Extrusion Housing

● Innovations in Aluminum Extrusion Housing

● Conclusion

● FAQ

>> 1. What are the primary benefits of using aluminum extrusion housing?

>> 2. How does aluminum compare to steel in terms of weight?

>> 3. Is aluminum extrusion environmentally friendly?

>> 4. Can aluminum extrusions be customized?

>> 5. What applications commonly use aluminum extrusion housing?

● Citations:

Aluminum extrusion housing has become a popular choice in various industries due to its unique properties and advantages over other materials. This article explores the reasons behind the increasing preference for aluminum extrusion housing, highlighting its benefits, applications, and comparisons with alternative materials.

Understanding Aluminum Extrusion

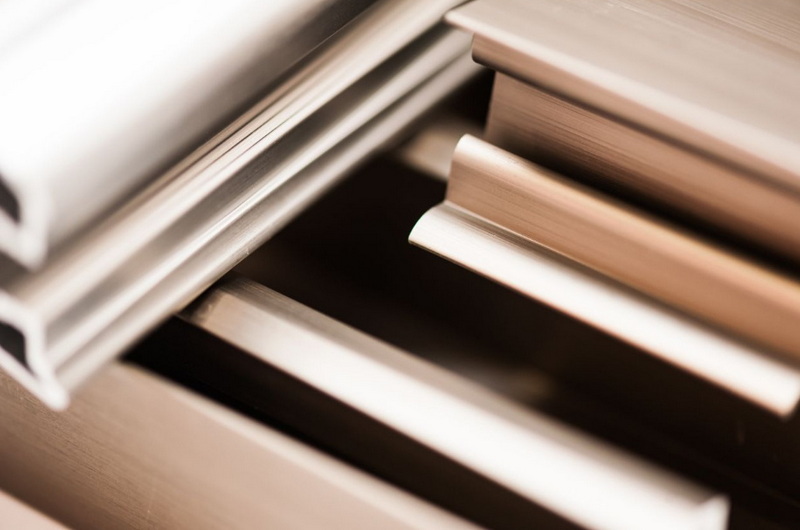

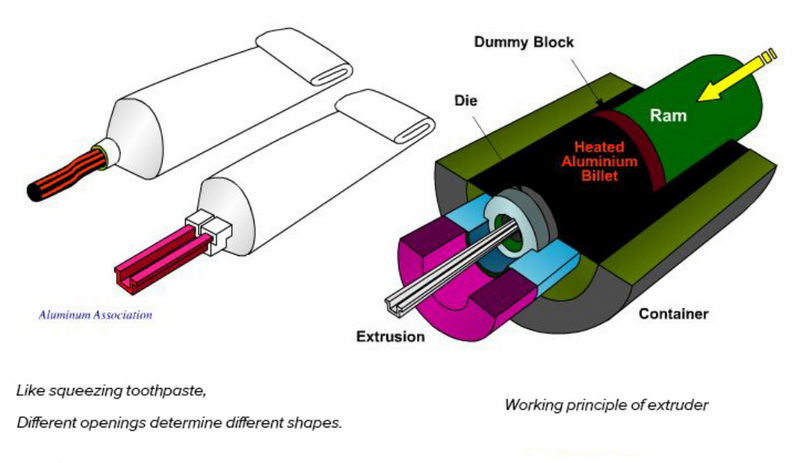

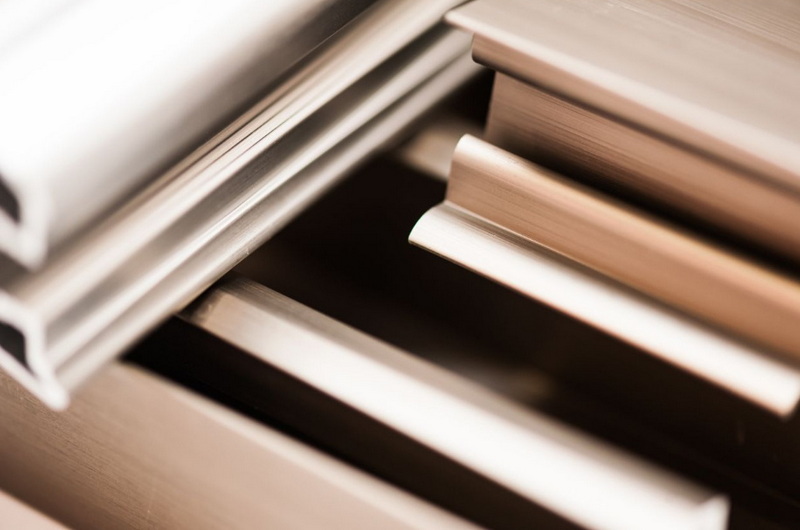

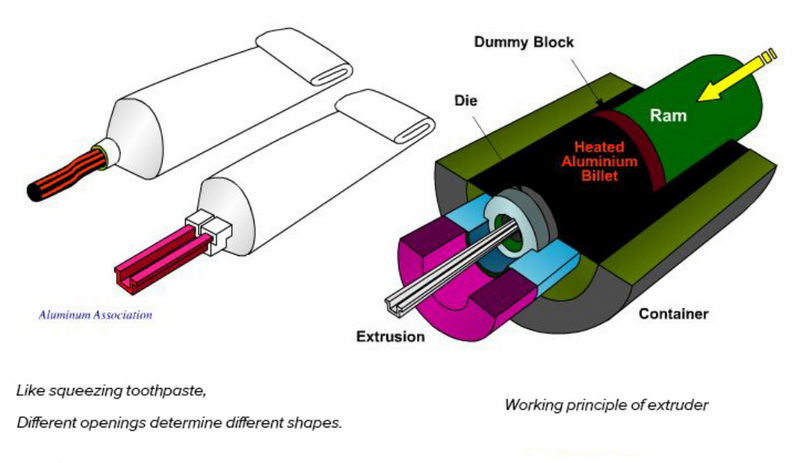

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy by forcing it through a die of the desired cross-section. This process allows for the production of complex shapes and profiles that can be tailored for specific applications. The resulting extrusions are lightweight, strong, and versatile, making them suitable for a wide range of uses, particularly in housing and construction.

Key Advantages of Aluminum Extrusion Housing

1. Lightweight Yet Strong

One of the most significant benefits of aluminum extrusion housing is its high strength-to-weight ratio. Aluminum is about one-third the weight of steel but can provide comparable strength. This characteristic makes it ideal for applications where weight reduction is crucial, such as in automotive and aerospace industries.

- Durability: Aluminum naturally forms a protective oxide layer that enhances its corrosion resistance, ensuring longevity even in harsh environments.

- Impact Resistance: Aluminum extrusions can absorb shock and resist deformation, making them suitable for construction applications that face weather-induced movements.

2. Excellent Thermal Conductivity

Aluminum is an excellent conductor of heat, which is particularly beneficial for applications requiring efficient heat dissipation. This property makes aluminum extrusion housing ideal for electronic enclosures and heat sinks.

- Heat Management: In electronics, aluminum extrusions are commonly used to manage heat effectively, preventing overheating and enhancing performance.

3. Versatility in Design

The aluminum extrusion process allows for a wide variety of shapes and profiles to be created, enabling architects and engineers to design innovative structures with unique aesthetics.

- Custom Solutions: Custom designs can be produced to meet specific requirements, from window frames to complex architectural elements.

- Finishing Options: Aluminum can be anodized, painted, or powder-coated to achieve desired finishes that enhance appearance and durability.

4. Cost-Effectiveness

While the initial cost of aluminum may be higher than some materials, its long-term benefits often outweigh these costs.

- Reduced Maintenance: Aluminum's corrosion resistance means lower maintenance costs over time compared to materials like steel that may require regular treatment.

- Efficiency in Production: The extrusion process is efficient, allowing for mass production with minimal waste, which can lower overall costs.

5. Environmental Sustainability

Aluminum is one of the most recyclable materials available today. The recycling process requires only 5% of the energy needed to produce new aluminum from ore.

- Sustainable Practices: Using recycled aluminum reduces environmental impact and promotes sustainability in construction practices.

Applications of Aluminum Extrusion Housing

Aluminum extrusion housing finds application across various sectors due to its advantageous properties:

- Construction: Used in window frames, door frames, curtain walls, and structural components.

- Automotive Industry: Lightweight components that enhance fuel efficiency while maintaining structural integrity.

- Electronics: Enclosures and heat sinks that require effective thermal management.

- Consumer Goods: Furniture and sporting goods benefit from aluminum's lightweight yet durable nature.

Comparison with Other Materials

When considering materials for housing solutions, it's essential to compare aluminum extrusion with alternatives such as steel or plastic. Below is a comparative analysis:

| Property | Aluminum Extrusion | Steel | Plastic |

| Weight | Lightweight | Heavy | Lightweight |

| Strength | High strength-to-weight ratio | High tensile strength | Lower strength |

| Corrosion Resistance | Excellent | Requires treatment | Varies by type |

| Thermal Conductivity | Excellent | Poor | Varies by type |

| Cost | Moderate initial cost | Lower initial cost | Low initial cost |

| Environmental Impact | Highly recyclable | Recyclable but energy-intensive | Varies; often non-recyclable |

Additional Benefits of Aluminum Extrusion Housing

6. Functionality and Versatility

Custom aluminum extrusion components can be fabricated to fit any project specification. This allows for total versatility, accommodating any size or shape required. As such, aluminum extrusion components have become integral in all types of construction projects.

- Wide Range of Applications: From window frame systems to roofing superstructures, aluminum meets various building construction requisites effectively.

7. Superb Structural Strength

Aluminum's exceptional structural strength is a significant benefit in housing construction. Its material strength is easily comparable to steel yet weighs only one-third as much. This quality ensures that aluminum extrusions deliver an excellent finished product without the added weight of steel.

- Performance in Extreme Conditions: Aluminum maintains its inherent properties even in extreme weather conditions, protecting buildings from cold far better than conventional brick.

8. High Corrosion Resistance

Resistance to corrosion is another advantage of aluminum—making it particularly optimal for building and housing construction. The alloys that comprise aluminum are corrosion-resistant, weatherproof, and immune to the negative effects of UV rays.

- Energy Efficiency: Aluminum is considered highly energy-efficient; it has won numerous awards in LEED-certified buildings (Leadership in Energy and Environmental Design) across the country.

Innovations in Aluminum Extrusion Housing

As technology advances, new innovations continue to enhance the capabilities of aluminum extrusion housing:

- Smart Home Integration: Modern designs incorporate smart technologies into aluminum framing systems for windows and doors, improving energy efficiency through automated controls.

- Enhanced Aesthetics: With advancements in finishing techniques such as powder coating and anodizing, architects can achieve stunning visual effects while maintaining durability.

Conclusion

Choosing aluminum extrusion housing offers numerous advantages over other materials, making it an optimal choice for various applications. Its lightweight nature combined with high strength, excellent thermal conductivity, versatility in design, cost-effectiveness, and environmental sustainability positions it as a superior option in modern construction and manufacturing practices. As industries continue to seek innovative solutions that balance performance with sustainability, aluminum extrusion housing will likely remain at the forefront.

FAQ

1. What are the primary benefits of using aluminum extrusion housing?

Aluminum extrusion housing offers a high strength-to-weight ratio, excellent thermal conductivity, corrosion resistance, design versatility, and environmental sustainability.

2. How does aluminum compare to steel in terms of weight?

Aluminum is approximately one-third the weight of steel while providing similar strength levels, making it advantageous for applications where weight reduction is essential.

3. Is aluminum extrusion environmentally friendly?

Yes! Aluminum is highly recyclable; using recycled aluminum consumes significantly less energy than producing new aluminum from raw materials.

4. Can aluminum extrusions be customized?

Absolutely! The extrusion process allows for custom shapes and profiles tailored to specific design requirements across various industries.

5. What applications commonly use aluminum extrusion housing?

Common applications include window frames, door frames, automotive components, electronic enclosures, and various consumer goods like furniture.

Citations:

[1] https://www.odmetals.com/blog/why-aluminum-extrusion-is-excellent-for-housing-construction

[2] http://scaluminum.com/2017/08/why-aluminum-extrusion-is-excellent-for-housing-construction/

[3] https://taberextrusions.com/aluminum-extrusions-material-comparisons/

[4] https://www.howardprecision.com/benefits-of-aluminum-extrusions/

[5] https://aec.org/residential

[6] https://globalaluminium.com/aluminium-extrusion-profiles-vs-stainless-steel-profiles/

[7] https://www.gabrian.com/6-key-reasons-to-choose-aluminum-extrusions-for-your-project/

[8] https://rpmindinc.com/aluminum-extrusions-uses-and-applications/

[9] https://amcaluminum.ph/benefits-of-locally-extruded-aluminum-homes/

[10] https://www.linkedin.com/pulse/7-common-applications-industrial-aluminum