Content Menu

● Understanding Aluminum Extrusion

● Advantages of Aluminum Extrusion

>> Lightweight yet Strong

>> Corrosion Resistance

>> Design Flexibility

>> Cost-Effective Manufacturing

>> Sustainability

● Applications of Aluminum Extrusion

>> Specialized Applications

● Why Choose Aluminum Extrusion for Your Project?

>> 1. Customization Options

>> 2. Enhanced Performance

>> 3. Rapid Production

>> 4. Reduced Assembly Time

>> 5. Aesthetic Appeal

● Innovations in Aluminum Extrusion

>> Advanced Die Design

>> 3D Printing Integration

>> Smart Manufacturing Techniques

● Conclusion

● FAQ

>> 1. What does aluminum extrusion mean?

>> 2. What are the benefits of using aluminum extrusion?

>> 3. What industries commonly use aluminum extrusion?

>> 4. How does aluminum compare to other materials?

>> 5. Can I customize my aluminum extrusions?

Aluminum extrusion is a manufacturing process that shapes aluminum alloys into specific profiles by forcing them through a die. This method has gained significant popularity across various industries due to its numerous advantages, including versatility, strength, and cost-effectiveness. In this article, we will explore the meaning of aluminum extrusion, its benefits, applications, and why it could be the ideal choice for your next project.

Understanding Aluminum Extrusion

What is Aluminum Extrusion?

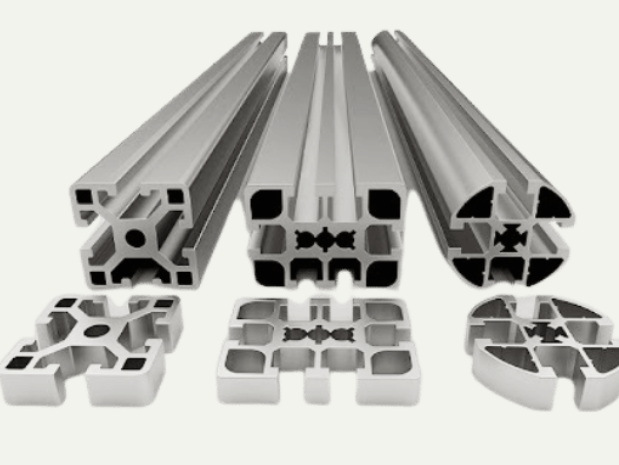

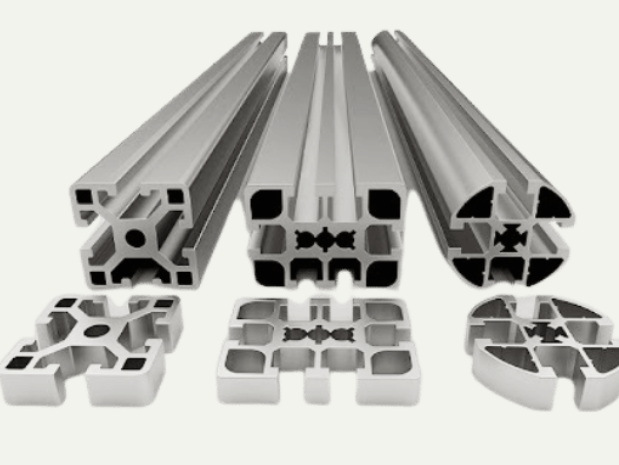

Aluminum extrusion involves heating aluminum billets until they become pliable and then pushing them through a die to create long shapes with a constant cross-section. The resulting profiles can be cut to any length and are used in a multitude of applications.

The Process of Aluminum Extrusion

1. Billet Preparation: The process starts with the preparation of aluminum billets, which are cylindrical pieces of aluminum alloy.

2. Heating: The billets are heated in a furnace to make them malleable.

3. Extrusion: Once heated, the billets are placed in an extrusion press where they are forced through a die under high pressure.

4. Cooling and Cutting: After exiting the die, the extruded aluminum is cooled and cut into desired lengths.

Advantages of Aluminum Extrusion

Aluminum extrusion offers several key benefits that make it an attractive option for manufacturers and designers alike:

Lightweight yet Strong

Aluminum is known for its lightweight properties while maintaining excellent strength. This makes it an ideal material for applications where weight reduction is crucial, such as in automotive and aerospace industries. The strength-to-weight ratio of aluminum is significantly higher than that of steel, allowing for lighter structures without compromising integrity.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer when exposed to air, making it highly resistant to corrosion. This property ensures longevity and durability in various environments, including coastal areas where saltwater can cause significant damage to other materials.

Design Flexibility

The extrusion process allows for complex shapes and designs that would be difficult or impossible to achieve with other manufacturing methods. This flexibility enables designers to create custom profiles tailored to specific needs. For example, intricate designs can be extruded that include features such as grooves or channels for wiring or plumbing.

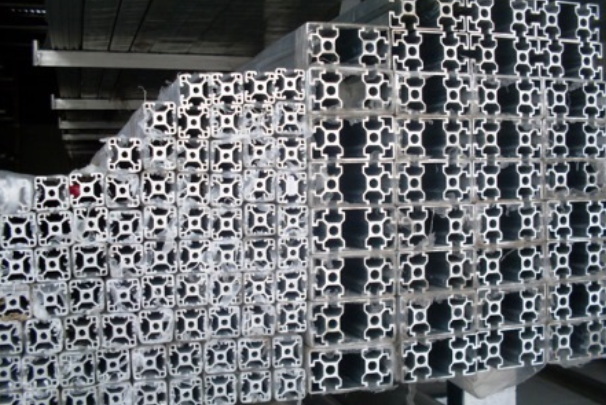

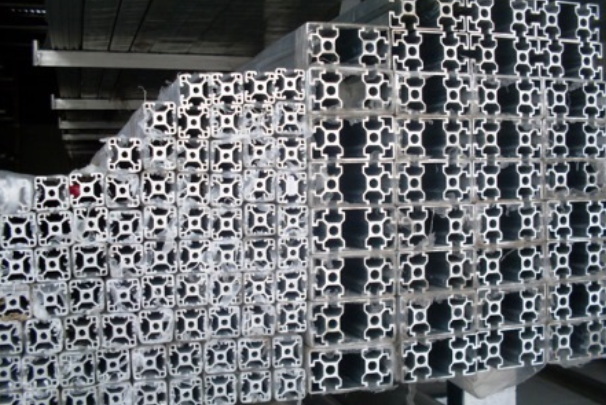

Cost-Effective Manufacturing

Aluminum extrusion is a cost-effective manufacturing process due to its efficiency and the reduced need for secondary operations. Once the die is created, producing large quantities of extruded profiles becomes economical. Additionally, the speed of production means lower labor costs over time.

Sustainability

Aluminum is 100% recyclable without losing its properties. Choosing aluminum extrusion supports sustainability efforts by reducing waste and energy consumption associated with traditional manufacturing processes. Recycling aluminum requires only 5% of the energy needed to produce new aluminum from ore, making it an environmentally friendly choice.

Applications of Aluminum Extrusion

Aluminum extrusion is utilized across various industries due to its versatility. Here are some common applications:

- Construction: Used in window frames, curtain walls, roofing systems, and structural components.

- Automotive: Employed in structural components such as chassis parts, heat exchangers, and body panels.

- Aerospace: Used in aircraft frames, wing structures, and interior components where weight reduction is essential.

- Electronics: Commonly found in enclosures for electronic devices, heat sinks for cooling systems, and connectors.

- Furniture: Utilized in modern furniture designs such as tables, chairs, shelving systems, and display cases.

Specialized Applications

Beyond these common applications, aluminum extrusion also finds use in specialized fields:

- Medical Equipment: Lightweight frames for medical devices and equipment that require portability.

- Sports Equipment: Custom profiles for bicycles, athletic gear, and sports facilities that benefit from lightweight yet strong materials.

- Renewable Energy: Components for solar panel frames and wind turbine structures that require durability against environmental factors.

Why Choose Aluminum Extrusion for Your Project?

When considering materials for your project, aluminum extrusion stands out for several reasons:

1. Customization Options

With aluminum extrusion, you can create custom profiles that meet your specific design requirements. Whether you need unique shapes or sizes, the extrusion process can accommodate your needs without significant additional costs.

2. Enhanced Performance

The mechanical properties of aluminum alloys used in extrusion provide enhanced performance characteristics such as improved strength-to-weight ratios and thermal conductivity. This makes aluminum an ideal choice for heat-sensitive applications like electronic housings where heat dissipation is critical.

3. Rapid Production

Once the initial die is created, the production speed of extruded aluminum parts is significantly faster than many other manufacturing methods. This rapid production capability can help meet tight deadlines without sacrificing quality.

4. Reduced Assembly Time

Many extruded profiles can be designed to include integrated features that reduce the need for additional assembly processes. This not only saves time but also reduces labor costs associated with assembling multiple components.

5. Aesthetic Appeal

Aluminum extrusions can be finished with various surface treatments such as anodizing or powder coating, allowing for aesthetically pleasing designs that can match any branding or style preferences. These finishes also enhance corrosion resistance and durability.

Innovations in Aluminum Extrusion

The field of aluminum extrusion continues to evolve with advancements in technology:

Advanced Die Design

Modern die design techniques allow manufacturers to create more complex shapes with tighter tolerances than ever before. This innovation expands the possibilities for what can be achieved through aluminum extrusion.

3D Printing Integration

Some manufacturers are exploring ways to integrate 3D printing technology with traditional aluminum extrusion methods. This hybrid approach allows for rapid prototyping alongside mass production capabilities.

Smart Manufacturing Techniques

The incorporation of smart manufacturing techniques such as automation and IoT (Internet of Things) technology enhances efficiency in the production process while ensuring quality control at every stage.

Conclusion

In conclusion, aluminum extrusion offers a multitude of benefits that make it an excellent choice for various projects across different industries. Its lightweight yet strong properties, corrosion resistance, design flexibility, cost-effectiveness, and sustainability make it a superior option compared to other materials. If you are considering materials for your next project, aluminum extrusion should be at the top of your list due to its versatility and performance advantages.

FAQ

1. What does aluminum extrusion mean?

Aluminum extrusion refers to the process of shaping aluminum alloys by forcing them through a die to create specific profiles with a constant cross-section.

2. What are the benefits of using aluminum extrusion?

The benefits include lightweight strength, corrosion resistance, design flexibility, cost-effectiveness in manufacturing, and sustainability due to recyclability.

3. What industries commonly use aluminum extrusion?

Common industries include construction, automotive, aerospace, electronics, furniture manufacturing, medical equipment production, sports equipment design, and renewable energy sectors.

4. How does aluminum compare to other materials?

Aluminum offers superior strength-to-weight ratios compared to steel and plastic while providing excellent corrosion resistance and design flexibility.

5. Can I customize my aluminum extrusions?

Yes! The extrusion process allows for extensive customization options regarding shape and size to meet specific project requirements.