Content Menu

● Understanding Aluminum Extrusion

● The Aluminum Extrusion Process

● Advantages of Aluminum Extrusion Building Systems

● Applications of Aluminum Extrusion in Building Projects

>> Innovative Uses of Aluminum Extrusions

● Key Considerations When Choosing Aluminum Extrusion

● Maintenance Considerations

● Future Trends in Aluminum Extrusion

● Conclusion

● FAQ

>> 1. What are the main benefits of using aluminum extrusion in construction?

>> 2. Can aluminum extrusions be used for structural framing?

>> 3. How does aluminum compare to steel in terms of cost?

>> 4. Are there any environmental benefits associated with aluminum extrusion?

>> 5. What types of projects benefit most from aluminum extrusion?

Aluminum extrusion has emerged as a favored choice in the construction industry, offering numerous advantages that cater to modern building needs. This article explores the benefits of aluminum extrusion building systems, detailing their applications, advantages, and considerations for your next project.

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that transforms aluminum alloy into specific shapes by forcing it through a die. This process allows for the creation of complex cross-sectional profiles that can be tailored to various applications. The versatility of aluminum extrusions makes them suitable for a wide range of structural and architectural uses.

The Aluminum Extrusion Process

The aluminum extrusion process involves several key steps:

1. Billet Preparation: A cylindrical piece of aluminum, known as a billet, is heated to a specific temperature to soften it for extrusion.

2. Extrusion: The heated billet is placed in an extrusion press where it is forced through a die under high pressure. This creates the desired shape.

3. Cooling: The extruded aluminum is cooled, typically by air or water, to solidify the shape.

4. Cutting and Finishing: Once cooled, the extruded sections are cut to length and may undergo additional finishing processes such as anodizing or powder coating for enhanced durability and aesthetics.

This process allows manufacturers to create intricate shapes that are not only functional but also visually appealing.

Advantages of Aluminum Extrusion Building Systems

1. Lightweight Yet Strong

One of the most significant benefits of aluminum extrusion is its favorable strength-to-weight ratio. Aluminum is approximately one-third the weight of steel but offers comparable strength, making it an ideal material for construction where weight is a concern. This characteristic allows for easier handling and installation, reducing labor costs.

2. Corrosion Resistance

Aluminum naturally forms a protective oxide layer when exposed to air, providing excellent corrosion resistance. This property is particularly advantageous in environments subject to moisture or chemicals, ensuring longevity and reducing maintenance costs.

3. Design Flexibility

The extrusion process allows for the creation of custom shapes and sizes, enabling architects and engineers to design innovative structures without the limitations imposed by traditional materials. This flexibility can lead to unique aesthetic designs that enhance the overall look of a building.

4. Sustainability

Aluminum is highly recyclable, making it an environmentally friendly choice for construction projects. Using recycled aluminum requires only 5% of the energy needed to produce new aluminum, significantly reducing the carbon footprint associated with building materials.

5. Cost-Effectiveness

While the initial investment in aluminum extrusion may be higher than some alternatives, its durability and low maintenance requirements can lead to cost savings over time. Additionally, the lightweight nature of aluminum can reduce transportation costs and simplify logistics during construction.

Applications of Aluminum Extrusion in Building Projects

Aluminum extrusion building systems are versatile and can be applied in various contexts:

- Structural Framing: Used in modular buildings and frameworks where lightweight yet strong materials are required.

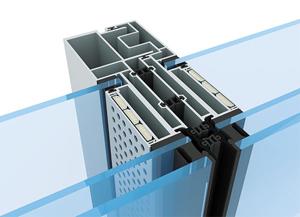

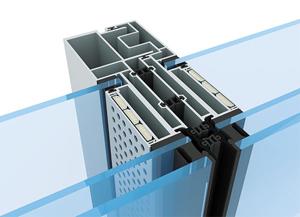

- Architectural Elements: Employed in window frames, curtain walls, and roofing systems due to their aesthetic appeal and structural integrity.

- Interior Applications: Commonly used in fixtures like lighting frames, display units, and furniture due to their design flexibility.

- Industrial Uses: Ideal for manufacturing equipment frames, conveyor systems, and safety barriers in factories.

Innovative Uses of Aluminum Extrusions

Beyond traditional applications, aluminum extrusions are finding innovative uses in modern construction:

- Green Building Solutions: With sustainability at the forefront of modern architecture, aluminum extrusions are increasingly used in green building projects. Their recyclability aligns with LEED certification requirements.

- Smart Building Technologies: As buildings become more integrated with technology, aluminum extrusions provide an ideal framework for housing smart sensors and other electronic components seamlessly within architectural designs.

- Modular Construction: The modular construction trend benefits greatly from aluminum extrusions due to their lightweight nature and ease of assembly. This method allows for faster construction times while maintaining high-quality standards.

Key Considerations When Choosing Aluminum Extrusion

While aluminum extrusion offers numerous benefits, there are some considerations to keep in mind:

- Thermal Conductivity: Although aluminum conducts heat well, it may not be suitable for all insulation needs without additional thermal breaks. Proper design considerations must be made to ensure energy efficiency.

- Cost Variability: Prices can fluctuate based on market conditions; however, long-term savings often outweigh initial costs. It's essential to conduct a thorough cost-benefit analysis when planning your project budget.

- Specialized Fabrication Needs: Depending on the complexity of your design, you may require specialized tooling or fabrication services. Collaborating with experienced manufacturers can help streamline this process.

Maintenance Considerations

Aluminum extrusions require minimal maintenance compared to other materials like wood or steel. Regular cleaning with mild soap and water can keep surfaces looking new. For projects exposed to harsh environments or coastal areas with salt exposure, additional protective coatings may enhance longevity even further.

Future Trends in Aluminum Extrusion

As technology continues to advance, several trends are shaping the future of aluminum extrusion in construction:

- 3D Printing Integration: The integration of 3D printing technologies with traditional extrusion methods could lead to more complex designs and reduced waste during manufacturing processes.

- Enhanced Coatings: Innovations in coatings will improve durability and aesthetic options for aluminum extrusions, allowing them to better withstand environmental challenges while offering diverse finishes.

- Smart Materials: Research into smart materials that respond dynamically to environmental changes could lead to exciting developments in how aluminum extrusions are utilized within smart buildings.

Conclusion

Choosing aluminum extrusion for your next building project presents an array of benefits including lightweight strength, corrosion resistance, design flexibility, sustainability, and cost-effectiveness. Its versatility makes it suitable for various applications ranging from structural framing to intricate architectural elements. As you plan your project, consider how aluminum extrusion building systems can enhance both functionality and aesthetics while contributing positively to environmental sustainability.

FAQ

1. What are the main benefits of using aluminum extrusion in construction?

Aluminum extrusion offers a lightweight yet strong material option that is resistant to corrosion and customizable for various designs. Its sustainability through recyclability also adds to its appeal.

2. Can aluminum extrusions be used for structural framing?

Yes, aluminum extrusions are commonly used for structural framing due to their high strength-to-weight ratio and ease of assembly.

3. How does aluminum compare to steel in terms of cost?

While aluminum may have a higher initial cost compared to steel, its durability and low maintenance needs can lead to significant long-term savings.

4. Are there any environmental benefits associated with aluminum extrusion?

Yes! Aluminum is highly recyclable and using recycled materials significantly reduces energy consumption compared to producing new aluminum.

5. What types of projects benefit most from aluminum extrusion?

Projects that require lightweight materials with high strength—such as modular buildings, architectural features, industrial equipment frames—greatly benefit from using aluminum extrusions.