Content Menu

● Understanding Aluminum Extrusion

● Advantages of Aluminum Extrusion Alloys

● Key Applications of Aluminum Extrusion Alloys

● Popular Aluminum Extrusion Alloys

● The Aluminum Extrusion Process

● Innovations in Aluminum Extrusion

● Conclusion

● FAQ

>> 1. What are the main benefits of using aluminum extrusion alloys?

>> 2. How does the strength-to-weight ratio of aluminum compare with other metals?

>> 3. What types of industries commonly use aluminum extrusions?

>> 4. Can aluminum extrusions be recycled?

>> 5. What are some common alloy types used in aluminum extrusions?

Aluminum extrusion alloys have become increasingly popular in various industries due to their unique properties and advantages over other metals. This article explores the reasons behind the growing preference for aluminum extrusion alloys, detailing their characteristics, applications, and benefits.

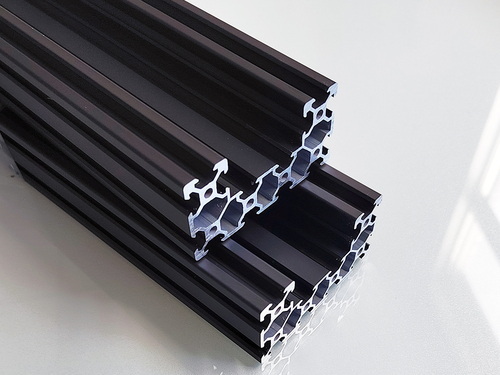

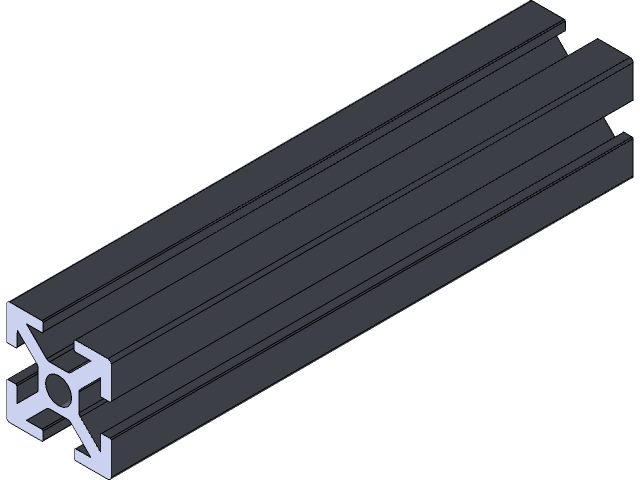

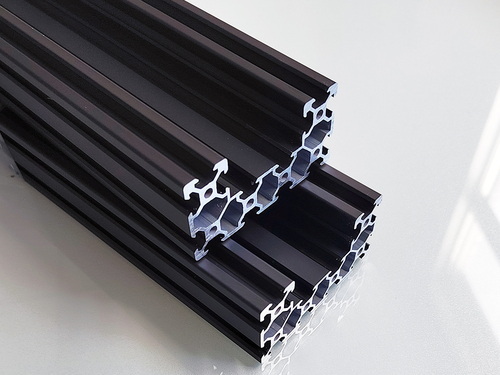

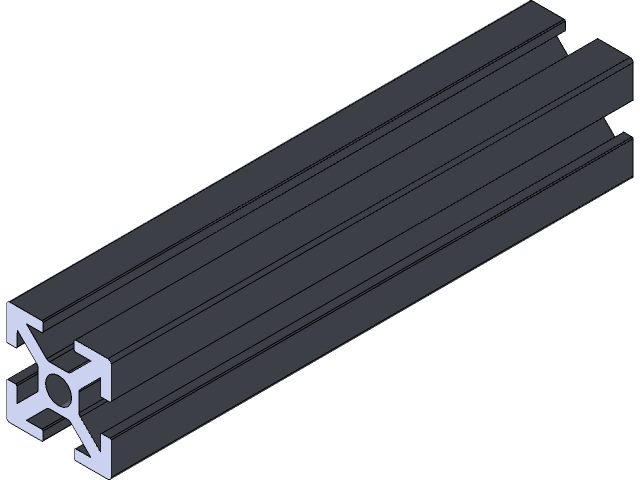

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that involves forcing aluminum alloy through a shaped die to create objects with a fixed cross-sectional profile. This versatile technique allows for the production of complex shapes and sizes tailored to specific applications, making aluminum extrusions a preferred choice in many sectors.

The extrusion process can be categorized into two main types: hot extrusion and cold extrusion.

- Hot Extrusion: In this method, the aluminum is heated above its recrystallization temperature, allowing for easier deformation. This technique is commonly used for producing larger and more complex shapes.

- Cold Extrusion: This process occurs at room temperature and is typically used for creating smaller components with tighter tolerances. Cold extrusion results in a stronger finished product due to the work hardening that occurs during the process.

Advantages of Aluminum Extrusion Alloys

The benefits of aluminum extrusion alloys are numerous and varied, making them an attractive option compared to other metals such as steel, copper, and magnesium. Here are some key advantages:

1. Lightweight Yet Strong

Aluminum is significantly lighter than steel, weighing approximately one-third as much while maintaining comparable strength. This high strength-to-weight ratio makes aluminum extrusion alloys ideal for applications where reducing weight is critical, such as in the aerospace and automotive industries.

For example, in the aerospace sector, reducing weight can lead to significant fuel savings and increased payload capacity. Similarly, in automotive design, lightweight materials contribute to improved fuel efficiency and lower emissions.

2. Corrosion Resistance

One of the standout features of aluminum is its natural resistance to corrosion. When exposed to air, aluminum forms a thin layer of aluminum oxide that protects it from further oxidation. This property eliminates the need for additional coatings or treatments in many cases, reducing maintenance costs and extending the lifespan of products made from aluminum extrusion alloys.

In contrast, metals like steel require protective coatings or galvanization to prevent rusting and corrosion, which can add to manufacturing costs and maintenance efforts.

3. Excellent Thermal Conductivity

Aluminum has superior thermal conductivity compared to many other metals, making it an excellent choice for applications requiring efficient heat dissipation. This property is particularly beneficial in electronics and HVAC systems, where managing heat is crucial for performance and longevity.

For instance, heat sinks made from aluminum extrusion alloys effectively dissipate heat away from electronic components, ensuring they operate within safe temperature ranges.

4. Design Flexibility

The extrusion process allows for a wide range of shapes and profiles, enabling designers to create custom components that meet specific requirements. This flexibility can lead to innovative designs that would be challenging or impossible to achieve with other materials.

Additionally, extruded aluminum can be easily machined or fabricated further, allowing for additional customization after the initial production phase.

5. Cost-Effectiveness

Aluminum extrusion alloys are often more cost-effective than other metals due to lower material costs and reduced shipping expenses thanks to their lightweight nature. Additionally, the efficiency of the extrusion process can lead to lower production costs.

The ability to produce complex shapes in a single operation reduces waste material and minimizes labor costs associated with assembly processes.

6. Sustainability

Aluminum is highly recyclable without losing its properties, making it an environmentally friendly choice. The recycling process consumes only 5% of the energy required to produce new aluminum from ore, contributing to reduced energy consumption and waste.

Furthermore, many companies are now focusing on sustainable practices by using recycled aluminum in their products, enhancing their overall environmental footprint.

Key Applications of Aluminum Extrusion Alloys

Aluminum extrusion alloys are utilized across various industries due to their unique properties:

- Aerospace: Lightweight components that do not compromise strength are essential in aircraft design. Aluminum extrusions are used in wings, fuselage frames, and interior structures.

- Automotive: Structural parts that enhance fuel efficiency by reducing vehicle weight are critical in modern automotive design. Aluminum extrusions are often found in chassis components and body panels.

- Construction: Window frames, roofing systems, and structural supports benefit from corrosion resistance and aesthetic appeal provided by aluminum extrusions.

- Electronics: Heat sinks and housings require efficient thermal management; thus, aluminum extrusions play a vital role in ensuring electronic devices operate effectively.

- Consumer Goods: Lightweight yet durable products such as furniture and appliances often incorporate aluminum extrusions for improved functionality and design aesthetics.

Popular Aluminum Extrusion Alloys

Different aluminum alloys offer varying characteristics suited for specific applications. Some of the most commonly used aluminum extrusion alloys include:

- 6061 Alloy: Known for its excellent mechanical properties and weldability; widely used in structural applications such as bridges and buildings.

- 6063 Alloy: Offers good extrudability and surface finish; commonly used for architectural applications like window frames and door frames due to its aesthetic appeal.

- 7075 Alloy: Known for its high strength-to-weight ratio; ideal for aerospace applications where performance is critical but weight must be minimized.

- 2024 Alloy: Often used in aerospace applications due to its high strength; however, it has lower corrosion resistance compared to 6061 or 6063 alloys.

The Aluminum Extrusion Process

The process of aluminum extrusion involves several steps:

1. Billet Preparation: Aluminum billets are cut into manageable lengths (typically around 20 feet) and heated to increase malleability. The heating temperature usually ranges between 350°C to 500°C depending on the alloy being used.

2. Extrusion: The heated billet is placed into an extrusion press where it is forced through a die under high pressure ranging from 1,000 to 20,000 psi. This step requires precise control over temperature and pressure to ensure quality output.

3. Cooling: The extruded shape is cooled using air or water sprays to stabilize its form quickly while preventing warping or distortion during cooling.

4. Stretching: The extruded material is stretched using mechanical stretching machines to eliminate internal stresses caused during the extrusion process. This step enhances dimensional accuracy.

5. Cutting: The extruded lengths are cut into specified sizes for further processing or delivery based on customer requirements or industry standards.

6. Finishing: Additional processes such as anodizing or powder coating can be applied for enhanced aesthetics (color options) and corrosion resistance (increased durability).

Innovations in Aluminum Extrusion

As technology advances, so does the aluminum extrusion industry. Innovations include:

- Advanced Alloys: Development of new alloy compositions that enhance mechanical properties while maintaining lightweight characteristics.

- 3D Printing Integration: Combining traditional extrusion methods with additive manufacturing techniques allows for hybrid designs that leverage both technologies' strengths.

- Smart Manufacturing: Implementation of Industry 4.0 technologies such as IoT sensors for real-time monitoring of production processes enhances quality control measures.

- Sustainable Practices: Increased focus on using renewable energy sources during production processes aims at reducing carbon footprints associated with manufacturing operations.

Conclusion

Choosing aluminum extrusion alloys over other metals offers numerous advantages including lightweight strength, corrosion resistance, excellent thermal conductivity, design flexibility, cost-effectiveness, and sustainability. These properties make aluminum extrusions suitable for a wide range of applications across various industries. As technology advances and demand grows, the use of aluminum extrusion alloys is expected to continue expanding into new markets and applications.

FAQ

1. What are the main benefits of using aluminum extrusion alloys?

Aluminum extrusion alloys provide lightweight strength, excellent corrosion resistance, high thermal conductivity, design flexibility, cost-effectiveness, and sustainability through recyclability.

2. How does the strength-to-weight ratio of aluminum compare with other metals?

Aluminum has a superior strength-to-weight ratio compared to many metals like steel and copper, making it ideal for applications where weight reduction is crucial.

3. What types of industries commonly use aluminum extrusions?

Industries such as aerospace, automotive, construction, electronics, and consumer goods frequently utilize aluminum extrusions due to their advantageous properties.

4. Can aluminum extrusions be recycled?

Yes! Aluminum is highly recyclable without losing its properties; this makes it an environmentally friendly option in manufacturing processes.

5. What are some common alloy types used in aluminum extrusions?

Common alloy types include 6061 (structural applications), 6063 (architectural applications), 7075 (aerospace applications), each offering unique characteristics suited for different uses.