Content Menu

● Understanding No Drying Extrusion Fertilizer Production Line

>> Key Components of the Production Line

● Advantages of No Drying Extrusion Fertilizer Production Line

● Operational Principles

● Applications in Agriculture

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What is a no drying extrusion fertilizer production line?

>> 2. What are the main benefits of using this production line?

>> 3. Can this production line handle organic materials?

>> 4. How does the granulation process work?

>> 5. Is this technology suitable for small-scale farms?

● Citations:

In the ever-evolving agricultural landscape, farmers are constantly seeking efficient and sustainable ways to enhance crop yields while minimizing environmental impact. One innovative solution that has gained traction is the "no drying extrusion fertilizer production line". This technology offers numerous advantages, making it an attractive option for modern farming practices. In this article, we will explore the benefits of this production line, its operational principles, and why it is a smart choice for your farm.

Understanding No Drying Extrusion Fertilizer Production Line

The no drying extrusion fertilizer production line utilizes a unique granulation process that eliminates the need for drying and cooling stages typically required in traditional fertilizer production methods. This process involves the mechanical extrusion of raw materials under high pressure, resulting in the formation of granules without the addition of water or heat.

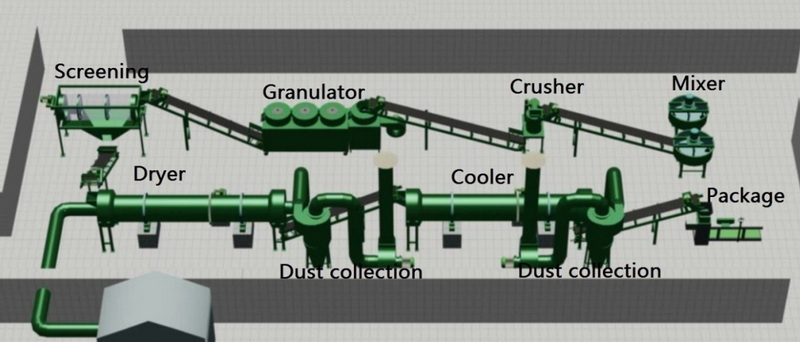

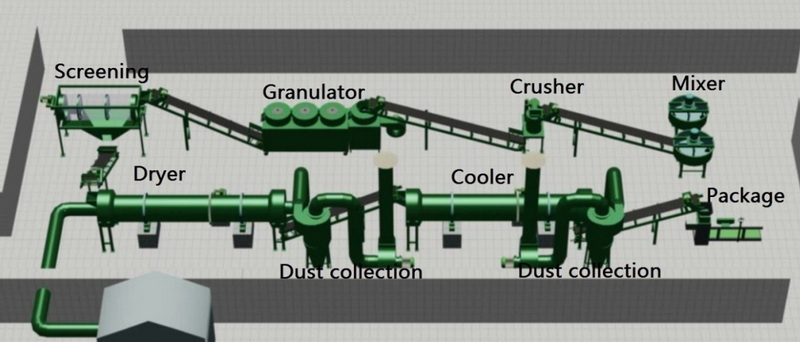

Key Components of the Production Line

- Raw Material Mixer: This machine combines various raw materials to create a homogeneous mixture suitable for granulation.

- Double Roller Extruder: The heart of the system, where the mixed raw materials are compressed into granules using high-pressure rollers.

- Screening Equipment: This separates qualified granules from oversized or undersized particles, ensuring uniformity in the final product.

- Packaging Machine: The final step involves packaging the finished granules for distribution and sale.

Advantages of No Drying Extrusion Fertilizer Production Line

1. Energy Efficiency

- The absence of drying processes significantly reduces energy consumption. Traditional methods often require substantial energy input for drying and cooling, while the no drying extrusion method operates at normal temperatures, conserving energy and lowering operational costs.

2. Cost Savings

- By eliminating the need for drying equipment, farmers can save on initial investment costs as well as ongoing operational expenses related to energy consumption and maintenance.

3. Environmental Benefits

- The no drying process produces minimal emissions and waste, contributing to a more sustainable agricultural practice. This method does not require additional fuel sources, thereby reducing greenhouse gas emissions associated with fertilizer production.

4. High Granulation Rate

- The extrusion process boasts a high granulation rate (up to 95%), ensuring that a significant percentage of the raw materials are converted into usable fertilizer granules.

5. Versatility

- This production line can accommodate a variety of raw materials, including organic and inorganic fertilizers. It is suitable for producing high, medium, and low concentration compound fertilizers tailored to specific crop needs.

6. Compact Design

- The layout of a no drying extrusion production line is typically more compact than traditional setups. This not only saves space but also simplifies installation and operation.

Operational Principles

The operation of a no drying extrusion fertilizer production line involves several key steps:

1. Raw Material Preparation:

- Raw materials such as urea, ammonium sulfate, potassium chloride, and other nutrients are precisely measured and mixed using an automated batching system to ensure accurate formulation.

2. Granulation Process:

- The mixed materials are fed into the double roller extruder where they are subjected to high pressure. This pressure compacts the materials into dense sheets.

3. Particle Formation:

- The compressed sheets are then broken down into granules through a crushing mechanism that ensures uniform particle size.

4. Screening:

- Oversized particles are separated out and returned to the mixer for reprocessing, ensuring that only granules within the desired size range proceed to packaging.

5. Packaging:

- Finally, the qualified granules are automatically packaged for distribution, ready to be used by farmers.

Applications in Agriculture

The no drying extrusion fertilizer production line is particularly beneficial for:

- Organic Farming: It allows farmers to produce organic fertilizers without chemical additives or excessive processing.

- NPK Fertilizers: It can efficiently produce nitrogen-phosphorus-potassium (NPK) fertilizers that are essential for balanced crop nutrition.

- Specialty Crops: Farmers growing specialty crops can customize their fertilizers based on specific nutrient requirements.

Conclusion

In conclusion, adopting a no drying extrusion fertilizer production line offers numerous advantages for modern farming operations. From energy efficiency and cost savings to environmental sustainability and versatility in application, this technology represents a significant step forward in fertilizer production practices. By investing in this innovative solution, farmers can enhance their productivity while contributing positively to environmental conservation efforts.

Frequently Asked Questions (FAQ)

1. What is a no drying extrusion fertilizer production line?

A no drying extrusion fertilizer production line is a system that produces fertilizer granules without requiring additional drying or cooling processes, utilizing mechanical extrusion under high pressure instead.

2. What are the main benefits of using this production line?

The main benefits include reduced energy consumption, lower operational costs, minimal environmental impact, high granulation rates, and versatility in producing various types of fertilizers.

3. Can this production line handle organic materials?

Yes, it is suitable for processing both organic and inorganic raw materials, making it versatile for different types of fertilizers.

4. How does the granulation process work?

The process involves mixing raw materials, extruding them under high pressure to form sheets, crushing these sheets into granules, screening for size uniformity, and packaging the final product.

5. Is this technology suitable for small-scale farms?

Absolutely! The compact design and low investment requirements make it an ideal choice for small-scale operations looking to enhance their fertilizer production capabilities.

Citations:

[1] https://organicfertilizermachines.com/compound-fertilizer-production-line/

[2] https://www.cementl.com/npk-compound-fertilizer-production-line-overview/

[3] https://www.yz-mac.com/no-drying-extrusion-compound-fertilizer-production-line-3-product/

[4] https://www.yz-mac.com/no-drying-extrusion-compound-fertilizer-production-lines/

[5] https://www.wastetofertilizer.com/dry-granulation-machine/

[6] https://fertilizerequipmentmanufacturer.com/fertilizer-roller-extrusion-granulation-line/

[7] https://www.cementl.com/solution/roller-press-extrusion-fertilizer-production-line/

[8] https://www.yz-mac.com/no-drying-extrusion-compound-fertilizer-production-line-product/

[9] https://www.fertilizer-machine.net/product/fertilizer-granulator/double-roller-extrusion-granulator.html

[10] https://fertilizerproductionlines.com/double-roller-granulator/

[11] https://www.yjing-extrusion.com/what-are-the-latest-innovations-in-no-drying-extrusion-granulation-production-lines.html

[12] https://www.linkedin.com/pulse/drying-dual-mode-extrusion-cylindrical-granulator-organic-yu-

[13] https://www.yz-mac.com/no-drying-extrusion-compound-fertilizer-production-lines/

[14] https://organicfertilizermachine.com/production-line/turnkey-organic-fertilizer-production-line

[15] https://fertilizerequipmentmanufacturer.com/fertilizer-granulation-equipment-video/

[16] https://winworkmachinery.com/npk-fertilizer-production-line/

[17] https://www.youtube.com/watch?v=zCg0cA9hK_4

[18] https://www.youtube.com/watch?v=CJ6GBJYFjVM

[19] https://fertilizer-machinery.com/production_line/compound-fertilizer-plant/extrusion-granulator-production-line.html

[20] https://www.youtube.com/watch?v=IoG1ZOx4WaU

[21] https://www.youtube.com/playlist?list=PL-yabeXo5FwSLFBlL4ZTHmp1dEdiGwIGu

[22] https://www.syfert.net/resources/compound-fertilizer-granulation-methods-process.html

[23] https://fertilizerequipmentmanufacturer.com/fertilizer-roller-extrusion-granulation-line/

[24] https://fertilizergranulatormanufacturer.com/npk-fertilizer-production-process/

[25] https://organicfertilizermachines.com/phosphate-fertilizer-plants/

[26] https://fertilizermanufacturingsolutions.com/dry-granulation-equipment-for-fertilizer/

[27] https://fertilizerequipmentmanufacturer.com/dry-granulation-equipment/

[28] https://organicfertilizermachine.com/faqs

[29] https://fertilizer-machine.net/solution_and_market/compound-fertilizer-production-line.html

[30] https://www.fertilizer-machine.net/solution_and_market/comparison-with-fertilizer-granulators.html

[31] https://www.cementl.com/solution/roller-press-extrusion-fertilizer-production-line/

[32] https://www.agrofertimac.com/production_line/organic-fertilizer-plant/flat-die-granulator-production-line.html

[33] https://fertilizerplantequiment.com/faq/