Content Menu

● Introduction to Monoprice Aluminum Extruders

>> Benefits of Aluminum Extruders

● Upgrading to a Monoprice Aluminum Extruder

>> Step-by-Step Upgrade Process

● Comparison with Plastic Extruders

● Monoprice Products and Aluminum Extrusions

>> Monoprice Select Mini

>> Monoprice Joule

● Advantages of Aluminum Extrusions in General

● Upgrading Other Components for Enhanced Performance

● Case Studies: Upgrading Popular Printers

● Conclusion

● FAQs

>> 1. What are the primary benefits of using an aluminum extruder over a plastic one?

>> 2. How do I upgrade my 3D printer to use an aluminum extruder?

>> 3. Are Monoprice printers compatible with aluminum extruders?

>> 4. What types of filaments can I use with an aluminum extruder?

>> 5. Do aluminum extruders require special maintenance?

● Citations:

In the realm of 3D printing, the choice of extruder material can significantly impact the performance and durability of your printer. Among the various options available, aluminum extruders have gained popularity due to their superior strength and thermal conductivity compared to plastic ones. This article will delve into the benefits of using a Monoprice aluminum extruder over plastic extruders, highlighting key advantages and providing insights into how these upgrades can enhance your 3D printing experience.

Introduction to Monoprice Aluminum Extruders

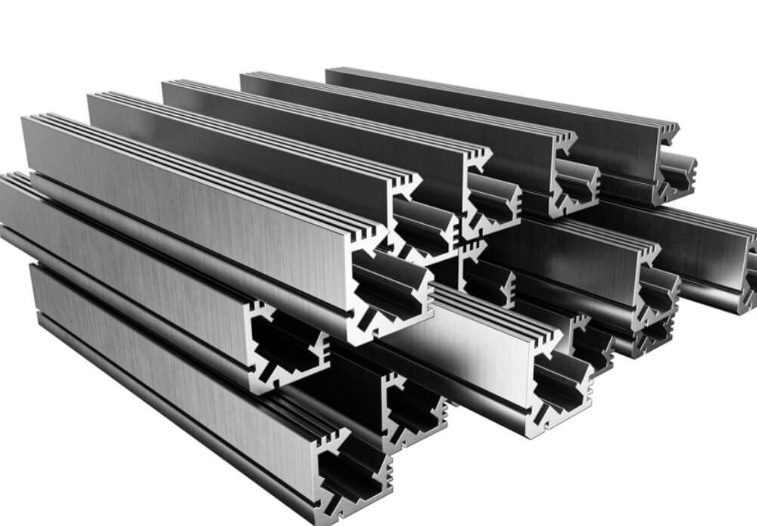

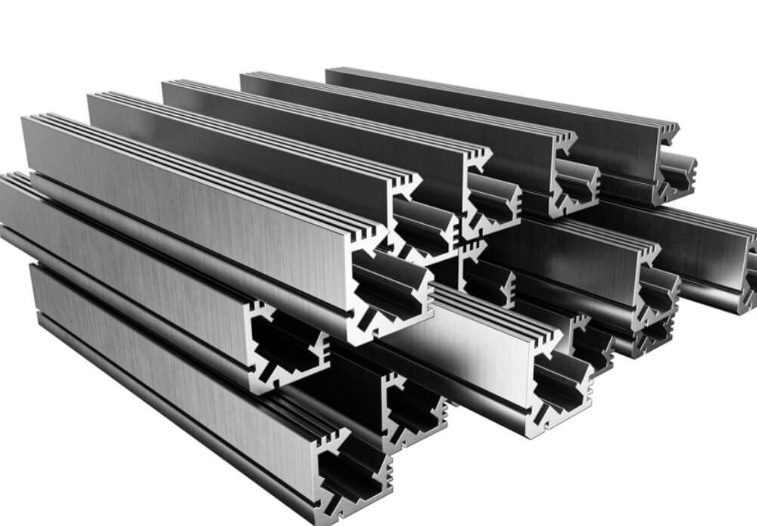

Monoprice is a well-known brand in the 3D printing community, offering a range of affordable and reliable products. Their aluminum extruders are designed to provide improved durability and performance compared to traditional plastic extruders. Aluminum extruders are crafted through a process that involves pushing aluminum through a die to create complex cross-sections, which enhances the metal's strength and reduces manufacturing costs.

Benefits of Aluminum Extruders

1. Durability: Aluminum extruders are more durable than plastic ones. They can withstand the high temperatures and mechanical stresses involved in the extrusion process without degrading over time.

2. Thermal Conductivity: Aluminum has better thermal conductivity than plastic, which helps in maintaining consistent temperatures during printing. This consistency is crucial for achieving high-quality prints, especially with materials like ABS and PETG.

3. Precision: Aluminum extruders can be manufactured with high precision, ensuring that the filament is fed consistently and accurately, which is vital for printing small details and complex models.

Upgrading to a Monoprice Aluminum Extruder

Upgrading from a plastic extruder to an aluminum one is relatively straightforward and can significantly improve your printer's performance. Here's a step-by-step guide on how to upgrade:

Step-by-Step Upgrade Process

1. Prepare the Printer: Ensure your printer is turned off and cool. Remove any filament from the extruder.

2. Disassemble the Stock Extruder: Follow the manufacturer's instructions to disassemble the stock plastic extruder. This typically involves removing screws and disconnecting electrical connections.

3. Install the Aluminum Extruder: Mount the new aluminum extruder in place of the old one. Ensure all connections are secure and properly aligned.

4. Test the Extruder: Once installed, test the extruder by running a few test prints to ensure everything is working correctly.

Comparison with Plastic Extruders

Plastic extruders are lighter and less expensive than aluminum ones but have several drawbacks:

- Heat Resistance: Plastic extruders can warp or degrade under high temperatures, affecting print quality and consistency.

- Mechanical Strength: Plastic is more prone to wear and tear, leading to issues like stripped gears or broken levers over time.

In contrast, aluminum extruders offer superior heat resistance and mechanical strength, making them a better choice for frequent use and complex prints.

Monoprice Products and Aluminum Extrusions

Monoprice offers a variety of 3D printing products, including printers like the Monoprice Select Mini and the Monoprice Joule. While these printers may not come with aluminum extruders by default, upgrading to one can enhance their performance significantly.

Monoprice Select Mini

The Monoprice Select Mini is a compact and affordable 3D printer that comes fully assembled and calibrated. It features a heated aluminum build plate, which is compatible with a wide range of filaments, including PLA, ABS, and PETG.

Monoprice Joule

The Monoprice Joule is another popular model that offers a larger build volume and advanced features like a color LCD interface. While it is similar to other clones in the market, its price point makes it an attractive option for those looking to upgrade their printing capabilities.

Advantages of Aluminum Extrusions in General

Aluminum extrusions offer several benefits beyond their use in 3D printing extruders. These include:

- Energy Efficiency: Aluminum extrusions can be produced with energy-saving processes, making them more environmentally friendly.

- Versatility: Aluminum can be extruded into various shapes and sizes, allowing for a wide range of applications.

- Strength and Durability: Products made from aluminum extrusions have increased strength and wear resistance, making them suitable for demanding applications.

Upgrading Other Components for Enhanced Performance

In addition to upgrading the extruder, other components can be improved to enhance your printer's performance:

- Bowden Tube Upgrade: Replacing the stock Bowden tube with a premium PTFE tube can improve filament flow and reduce friction, leading to smoother prints.

- Extruder Gear Upgrade: Installing a better extruder gear with finer teeth can improve filament grip, reducing slippage and enhancing print quality.

Case Studies: Upgrading Popular Printers

Upgrading popular printers like the Creality Ender 3 V2 with an aluminum extruder can significantly improve their performance. For instance, the Ender 3 V2 benefits from the enhanced durability and thermal conductivity of aluminum extruders, allowing for more consistent prints and better handling of high-temperature filaments.

Conclusion

Choosing a Monoprice aluminum extruder over a plastic one can significantly enhance your 3D printing experience. Aluminum extruders offer better durability, thermal conductivity, and precision, making them ideal for printing complex models and using a variety of filaments. Whether you're upgrading an existing printer or purchasing a new one, considering an aluminum extruder can be a worthwhile investment.

FAQs

1. What are the primary benefits of using an aluminum extruder over a plastic one?

- Durability: Aluminum extruders are more resistant to wear and tear.

- Thermal Conductivity: Better heat management leads to more consistent prints.

- Precision: Ensures consistent filament feeding for detailed prints.

2. How do I upgrade my 3D printer to use an aluminum extruder?

- Disassemble the stock extruder, then install the new aluminum extruder. Ensure all connections are secure and properly aligned.

3. Are Monoprice printers compatible with aluminum extruders?

- Yes, Monoprice printers can be upgraded with aluminum extruders. However, check compatibility with your specific model before purchasing.

4. What types of filaments can I use with an aluminum extruder?

- Aluminum extruders support a wide range of filaments, including PLA, ABS, PETG, and more, due to their superior heat management.

5. Do aluminum extruders require special maintenance?

- Regular cleaning and ensuring proper alignment are essential. However, aluminum extruders generally require less maintenance than plastic ones due to their durability.

Citations:

[1] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[2] https://www.youtube.com/watch?v=KP6uxwt6pV4

[3] https://forum.flitetest.com/index.php?threads%2Fextruder-upgrade-e3d-titan.38247%2F

[4] https://letsprint3d.net/upgrade-extruder-gear/

[5] https://www.ifixit.com/Guide/MP+Select+Delta+Mini+Extruder+Replacement/143190

[6] https://www.yjing-extrusion.com/is-it-worth-buying-an-aluminum-extruder-for-my-3d-printer.html

[7] https://www.youtube.com/watch?v=UtemZqFJ5rY

[8] https://www.cnet.com/reviews/monoprice-dual-extrusion-3d-printer-review/

[9] https://www.made-in-china.com/products-search/hot-china-products/Aluminum_Extrusion_Extruder_Price.html

[10] https://www.ubuy.com.bd/en/product/12VNN4Z4-chpower-cr-10-extruder-upgraded-replacement-aluminum-mk8-drive-feed-3d-printer-extruders-for-crealit

[11] https://www.reddit.com/r/MPSelectMiniOwners/comments/fbd81b/recommend_an_upgraded_extruder/

[12] https://www.dynisco.com/userfiles/files/27429_Legacy_Txt.pdf

[13] https://aec.org/features-benefits

[14] https://hackaday.io/project/28433-monoprice-select-mini-painless-extruder-upgrade

[15] https://www.reddit.com/r/3Dprinting/comments/16vzxk8/why_does_almost_every_diy_printer_use_aluminium/

[16] https://downloads.monoprice.com/files/manuals/13860_Manual_151111.pdf

[17] https://www.monoprice.com/pages/3d_printers

[18] https://hackaday.io/project/28433/instructions

[19] https://www.printer3d.one/monoprice-maker-ultimate-3d-printer-review-2017-mk11-directdrive-extruder-24v-power-system/

[20] https://www.youtube.com/watch?v=_7DyBOGg3Co