Content Menu

● Introduction to Aluminum Extrusion

>> Advantages of Aluminum Extrusions

● Benefits of Choosing a China Aluminum Extruder

>> Cost Efficiency

>> Technological Advancements

>> Government Support

>> Market Dominance

>> Customization and Flexibility

● Applications of Aluminum Extrusions

● How Aluminum Extrusion Works

● Choosing the Right China Aluminum Extruder

● Conclusion

● FAQs

>> 1. What are the common aluminum alloys used in extrusion?

>> 2. How does the cost of aluminum extrusions compare to other metals?

>> 3. What surface treatments are available for aluminum extrusions?

>> 4. What is the typical lead time for aluminum extrusion production?

>> 5. How sustainable is the aluminum extrusion process?

● Citations:

In today's global market, aluminum extrusions play a crucial role in various industries, including construction, automotive, and electronics. China has emerged as the world's largest producer and exporter of aluminum extrusions, accounting for over 70% of global production[1]. This dominance is attributed to factors such as low costs, technological advancements, and government support. Here, we explore why choosing a China aluminum extruder can be beneficial for your business.

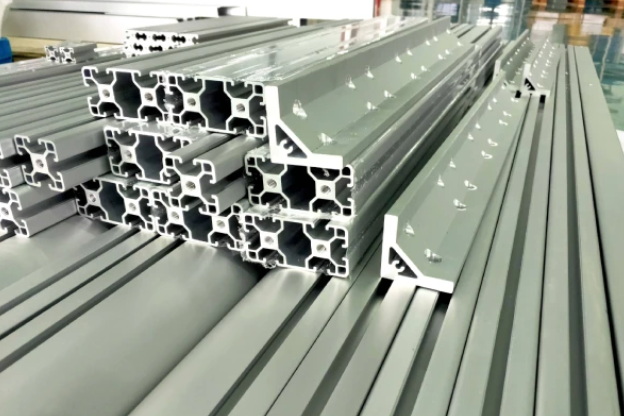

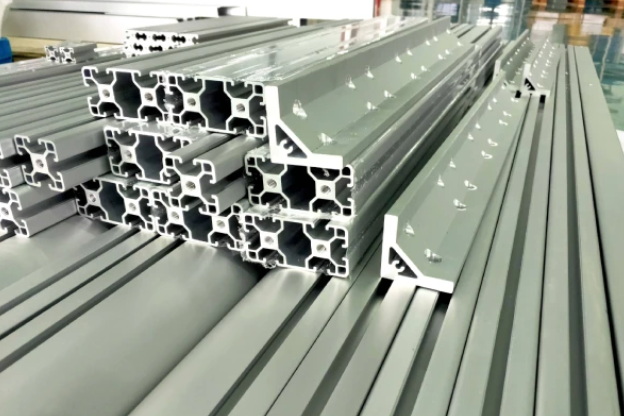

Introduction to Aluminum Extrusion

Aluminum extrusion is a manufacturing process that involves forcing heated aluminum through a die to create specific shapes. This process allows for the production of complex profiles with high precision and uniformity. The versatility of aluminum extrusions makes them ideal for a wide range of applications, from building frames to automotive parts.

Advantages of Aluminum Extrusions

1. Lightweight and High Strength: Aluminum extrusions are significantly lighter than steel while maintaining high tensile and bending strength, making them ideal for applications where weight reduction is crucial[3][9].

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which can be further enhanced through surface treatments like anodizing[3][9].

3. Design Flexibility: The extrusion process allows for the creation of complex shapes and designs, enabling customization to meet specific project requirements[9].

4. Cost-Effectiveness: Aluminum extrusions often have lower production and shipping costs compared to other metals due to their lightweight nature and efficient manufacturing process[9].

5. Sustainability: Aluminum is highly recyclable, reducing waste and supporting environmental sustainability[9].

Benefits of Choosing a China Aluminum Extruder

Cost Efficiency

China aluminum extruders offer competitive pricing due to lower labor and operational costs. This cost advantage allows businesses to reduce their overall expenses without compromising on quality[1].

Technological Advancements

Chinese manufacturers have invested heavily in advanced equipment and technology, enabling them to produce high-quality extrusions efficiently. This includes state-of-the-art extrusion presses and surface treatment facilities[1][4].

Government Support

The Chinese government provides incentives and support to the aluminum extrusion industry, fostering a favorable business environment. This support includes financial incentives and regulatory assistance, helping companies to innovate and expand[1].

Market Dominance

China's dominance in the global aluminum extrusion market means that businesses can tap into a vast network of suppliers and manufacturers. This ensures a stable supply chain and access to a wide range of products[1].

Customization and Flexibility

China aluminum extruders offer customization services, allowing businesses to design extrusions tailored to their specific needs. This flexibility is crucial for industries requiring unique profiles and designs[3][9].

Applications of Aluminum Extrusions

Aluminum extrusions are used in a variety of industries due to their versatility and benefits:

- Construction: Aluminum profiles are used in building frames, windows, and doors due to their strength, corrosion resistance, and aesthetic appeal[3].

- Automotive: Extrusions are used for vehicle frames, engine components, and other parts where lightweight yet strong materials are required[8].

- Electronics: Aluminum is used in electronic components and enclosures due to its electrical conductivity and corrosion resistance[9].

How Aluminum Extrusion Works

The aluminum extrusion process involves several key steps:

1. Die Preparation: The extrusion die is preheated to ensure even metal flow[6].

2. Billet Heating: The aluminum billet is heated to a semi-plastic state[6].

3. Extrusion: The billet is forced through the die to create the desired profile[6].

4. Cooling and Stretching: The extruded profile is cooled and stretched to achieve precise dimensions[6][8].

Choosing the Right China Aluminum Extruder

When selecting a China aluminum extruder, consider the following factors:

- Experience and Reputation: Look for manufacturers with a long history of producing high-quality extrusions[3].

- Technological Capabilities: Ensure the manufacturer has advanced equipment and technology to meet your production needs[4].

- Customization Options: Choose a supplier that offers customization services to meet your specific design requirements[3].

- Quality Certifications: Ensure the manufacturer holds relevant quality certifications such as ISO 9001[10].

Conclusion

Choosing a China aluminum extruder can be a strategic decision for businesses seeking cost-effective, high-quality aluminum extrusions. With China's dominance in the global market, businesses can leverage the advantages of technological advancements, government support, and customization options. Whether you are in construction, automotive, or electronics, partnering with a China aluminum extruder can enhance your product offerings and competitiveness.

FAQs

1. What are the common aluminum alloys used in extrusion?

The most commonly used aluminum alloys for extrusion are the 6000 series, known for their strength and corrosion resistance. However, other series like 3000, 5000, and 7000 are also used depending on specific application requirements[7].

2. How does the cost of aluminum extrusions compare to other metals?

Aluminum extrusions are generally more cost-effective than other metals due to lower material and shipping costs. The extrusion process also minimizes material waste, contributing to cost savings[9].

3. What surface treatments are available for aluminum extrusions?

Common surface treatments include anodizing, powder coating, and electrophoresis. These treatments enhance corrosion resistance and provide aesthetic finishes[7][10].

4. What is the typical lead time for aluminum extrusion production?

Lead times vary based on factors such as order size and design complexity. Generally, it takes 10-25 days for tooling creation and 20-25 days for bulk production[7].

5. How sustainable is the aluminum extrusion process?

The aluminum extrusion process is highly sustainable due to aluminum's recyclability and the efficient use of materials. This reduces waste and supports environmental conservation efforts[9].

Citations:

[1] https://www.goldapple-alu.com/how-chinese-aluminum-extrusions-are-shaping-the-global-market.html

[2] https://www.linkedin.com/pulse/advantages-aluminum-extrusions-grace-gao

[3] https://www.zp-aluminium.com/aluminum-extrusion/

[4] https://www.alu4all.com/equipment-and-system/

[5] https://www.youtube.com/watch?v=2OKk3rbsdRo

[6] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[7] https://www.sourcifychina.com/aluminum-extrusion-guide-in-depth/

[8] https://aec.org/faqs

[9] https://www.yjing-extrusion.com/what-are-the-key-benefits-of-the-aluminum-extruder-19116.html

[10] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[11] https://www.sourcifychina.com/aluminium-extrusion-guide-in-depth/

[12] https://www.goldapple-alu.com/ms/the-benefits-of-choosing-chinese-aluminum-extrusions-for-your-projects.html

[13] https://www.goldapple-alu.com/si/the-benefits-of-choosing-chinese-aluminum-extrusions-for-your-projects.html

[14] https://www.yjing-extrusion.com/what-industries-use-aluminum-extruders-in-china.html

[15] https://www.alu4all.com/aluminum-extrusion/

[16] https://www.sunrise-metal.com/what-benefits-and-applications-are-there-for-machined-aluminum-extrusion/

[17] https://www.guangyaaluminium.com/blog/what-are-the-advantages-and-disadvantages-of-extruded-aluminum-profiles_b8

[18] https://www.alu4all.com/how-aluminum-extrusion-enhances-product-design-and-functionality/

[19] https://profiledecor.com/benefits-of-aluminum-extrusion/