Content Menu

● Introduction to 3030 Aluminum Extrusion

● What is a Magnetic Extruder?

● Why Use 3030 Aluminum Extrusion in a Magnetic Extruder?

● Designing a Magnetic Extruder with 3030 Aluminum Extrusion

● Applications of 3030 Aluminum Extrusion in 3D Printing

● Advantages over Other Materials

● Real-World Examples and Case Studies

● Conclusion

● Frequently Asked Questions (FAQ)

>> Q1: What is 3030 aluminum extrusion?

>> Q2: What are the main benefits of using 3030 aluminum extrusion in a 3D printer?

>> Q3: How does 3030 aluminum extrusion contribute to better print quality?

>> Q4: Can 3030 aluminum extrusion be easily customized for specific 3D printer designs?

>> Q5: Is 3030 aluminum extrusion a cost-effective material for building 3D printers?

● Citations:

3D printing has revolutionized manufacturing, allowing creators to produce complex parts and prototypes with ease. As the technology advances, so do the components and materials used to build and enhance 3D printers. One critical component is the extruder, which feeds filament to the hot end to create the printed object. A popular choice for building robust and precise extruders is the 3030 aluminum extrusion. This article explores the benefits, applications, and design considerations of using 3030 aluminum extrusion in 3D printer magnetic extruders.

Introduction to 3030 Aluminum Extrusion

3030 aluminum extrusion refers to an aluminum profile with a cross-section of approximately 30mm x 30mm. Aluminum extrusion involves forcing heated aluminum billet through a die to create a specific shape[3]. The resulting profiles are lightweight, strong, and versatile, making them ideal for various structural and mechanical applications[1].

Key Properties of 3030 Aluminum Extrusion:

- High Strength-to-Weight Ratio: Aluminum is a lightweight material with considerable strength, making it perfect for applications where weight is a concern[1].

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, providing excellent resistance to corrosion[13].

- Thermal Conductivity: Aluminum's ability to conduct heat makes it useful in applications requiring heat dissipation[13].

- Modularity: Extrusion profiles often include T-slots or V-slots, allowing easy assembly and attachment of various components[1].

- Customization: Aluminum extrusions can be easily cut, drilled, and machined to meet specific design requirements[1].

- Recyclability: Aluminum can be recycled without losing its properties, making it an environmentally friendly material[1].

What is a Magnetic Extruder?

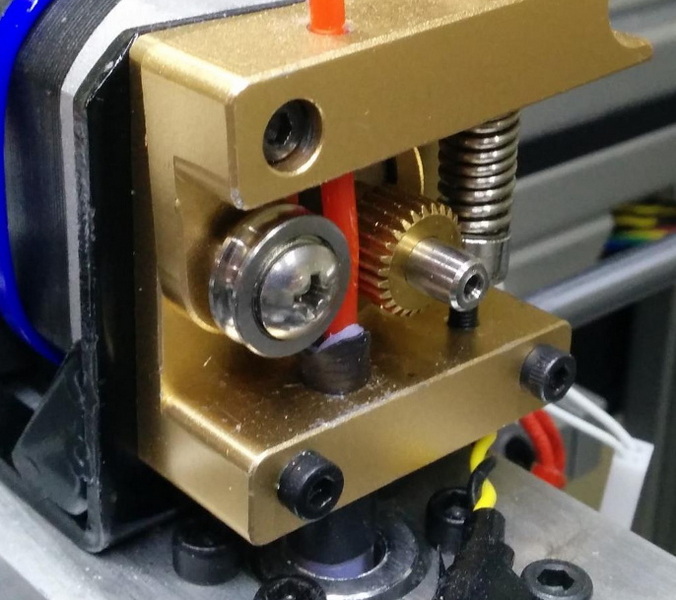

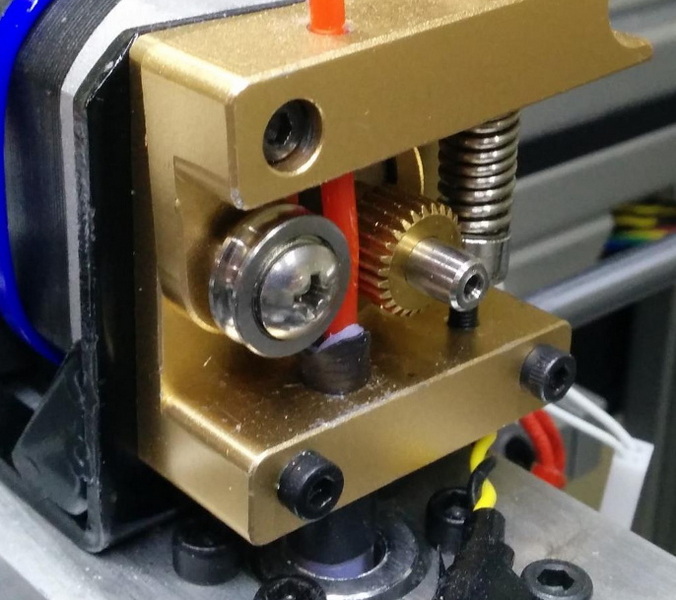

A magnetic extruder utilizes magnetic force to drive the filament feeding mechanism. Traditional extruders often rely on gears and mechanical linkages, which can introduce backlash and wear over time. Magnetic extruders, however, offer a more direct and responsive control over filament feeding, enhancing print precision and reliability.

Advantages of Magnetic Extruders:

- Reduced Backlash: Magnetic coupling minimizes mechanical play, resulting in more accurate and consistent filament feeding.

- Improved Responsiveness: Direct magnetic drive allows for quick and precise adjustments to filament flow, crucial for detailed prints.

- Lower Noise: Eliminating gears reduces mechanical noise during operation, leading to a quieter printing experience.

- Reduced Wear: Fewer mechanical parts mean less wear and tear, extending the lifespan of the extruder.

- Higher Precision: The precise control offered by magnetic extruders results in smoother surfaces and more accurate details in printed parts.

Why Use 3030 Aluminum Extrusion in a Magnetic Extruder?

Combining 3030 aluminum extrusion with a magnetic extruder design offers numerous advantages for 3D printer performance and reliability.

1. Structural Stability and Rigidity:

The primary benefit of using 3030 aluminum extrusion is its ability to provide a stable and rigid frame for the extruder assembly. A magnetic extruder needs a solid foundation to ensure precise and consistent filament delivery. The 3030 aluminum profile provides excellent support, minimizing vibrations and ensuring accurate movement[1].

2. Modularity and Ease of Assembly:

3030 aluminum extrusion profiles come with T-slots or V-slots, which allow for easy mounting of various components such as motors, bearings, and filament guides[1]. This modularity simplifies the assembly process and allows for easy adjustments and upgrades.

3. Heat Dissipation:

Extruders, especially those driving high volumes of filament, can generate significant heat. Aluminum's excellent thermal conductivity helps dissipate this heat, preventing overheating and maintaining consistent performance.

4. Customization and Design Flexibility:

The ease with which aluminum extrusion can be cut, drilled, and machined allows for highly customized extruder designs. This is particularly useful for magnetic extruders, where precise alignment and mounting of magnetic components are critical.

5. Vibration Dampening:

The inherent rigidity and mass of the 3030 aluminum extrusion help dampen vibrations, which can negatively affect print quality. By reducing vibrations, the extruder can maintain a more stable and consistent filament flow.

6. Durability and Longevity:

Aluminum is a durable material that can withstand the rigors of continuous 3D printing[1]. A 3030 aluminum extruder frame will provide long-lasting support and maintain its structural integrity over time, ensuring consistent performance.

Designing a Magnetic Extruder with 3030 Aluminum Extrusion

Designing a magnetic extruder using 3030 aluminum extrusion involves several key considerations to maximize performance and reliability.

1. Frame Design:

The frame should be designed to provide maximum rigidity and stability. Using CAD software, create a design that incorporates the necessary mounting points for the motor, bearings, filament guides, and magnetic components. Ensure that the frame is adequately braced to prevent flexing or twisting during operation.

2. Component Mounting:

Utilize the T-slots or V-slots in the aluminum extrusion to mount components securely. Use appropriate fasteners such as T-nuts and screws to ensure a tight and stable connection. Consider using vibration-dampening mounts for the motor to further reduce noise and vibration.

3. Magnetic System Design:

Carefully design the magnetic system to provide the required torque and responsiveness for filament feeding. Use high-quality magnets and ensure they are properly aligned and secured to the frame. Consider using adjustable mounts to fine-tune the magnetic force.

4. Filament Path:

Design the filament path to minimize friction and ensure smooth feeding. Use PTFE tubing or other low-friction materials to guide the filament from the spool to the hot end. Ensure that the filament path is free of sharp bends or obstructions.

5. Cooling System:

Implement a cooling system to dissipate heat generated by the motor and magnetic components. Use a combination of heat sinks and fans to maintain a stable operating temperature. Ensure that the cooling system does not introduce excessive noise or vibration.

Applications of 3030 Aluminum Extrusion in 3D Printing

Beyond magnetic extruders, 3030 aluminum extrusion is widely used in various other 3D printer components and applications.

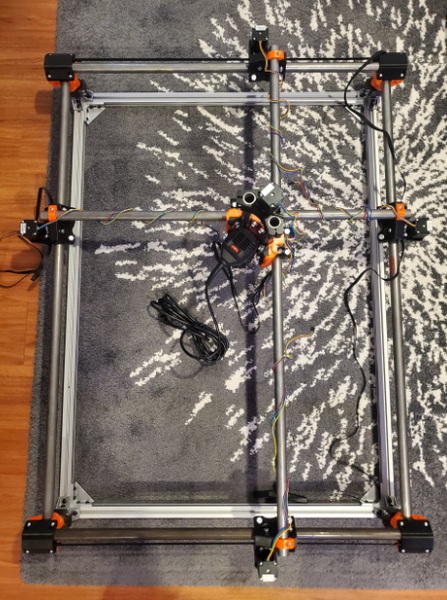

1. Printer Frames:

3030 aluminum extrusion is commonly used to construct the main frame of 3D printers[1]. Its rigidity and modularity make it ideal for creating a stable and customizable platform.

2. Enclosures:

Aluminum extrusion can be used to build enclosures for 3D printers, providing a controlled environment for printing temperature-sensitive materials.

3. Linear Motion Systems:

Aluminum extrusion profiles are often used as the base for linear rails and bearings, providing smooth and accurate motion for the print head and build platform.

4. Custom Tooling:

The ease of machining and customization makes aluminum extrusion suitable for creating custom tooling and fixtures for 3D printing applications.

Advantages over Other Materials

When compared to other materials like steel or plastic, 3030 aluminum extrusion offers distinct advantages in 3D printer applications.

| Material | Advantages | Disadvantages |

| 3030 Aluminum | Lightweight, high strength-to-weight ratio, corrosion-resistant, excellent thermal conductivity, modular, customizable, vibration dampening, durable1. | Higher cost than steel or plastic, requires specialized tools for cutting and machining. |

| Steel | High strength, low cost | Heavy, prone to corrosion, lower thermal conductivity, less modular, difficult to customize. |

| Plastic | Lightweight, low cost, easy to mold | Lower strength, susceptible to warping and deformation, poor thermal conductivity, less durable, can be difficult to achieve high precision. |

Real-World Examples and Case Studies

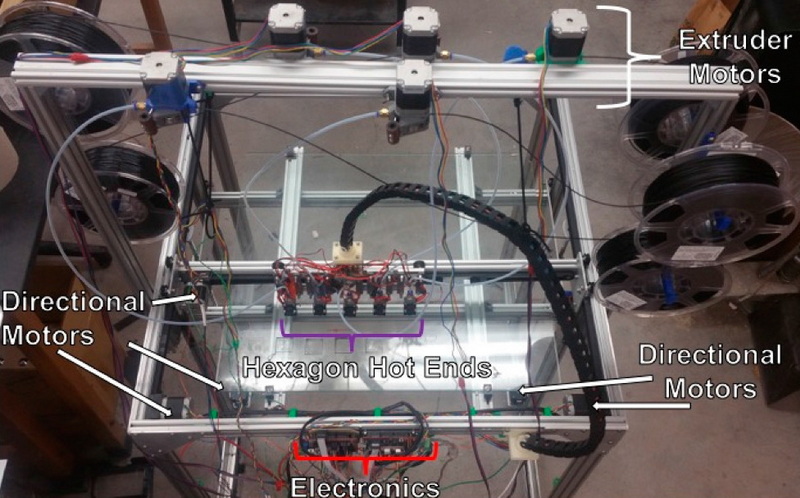

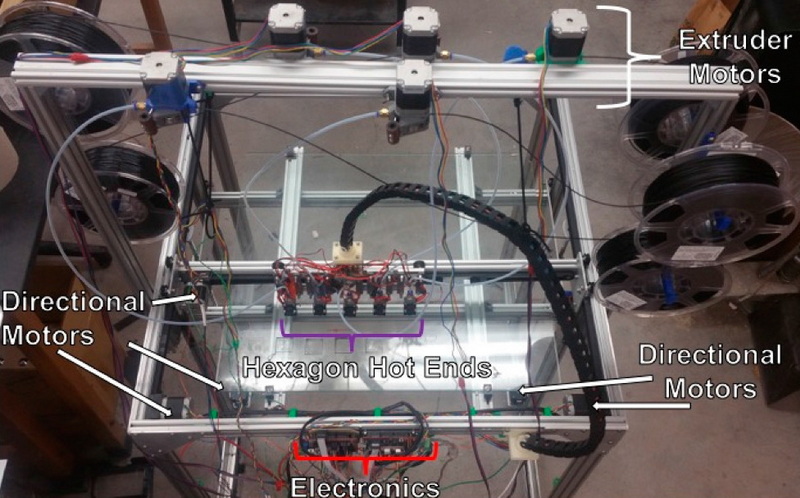

Case Study 1: High-Precision Extruder

A research team at a leading university developed a high-precision magnetic extruder using 3030 aluminum extrusion. The frame's rigidity and stability allowed them to achieve extremely accurate filament control, resulting in prints with superior surface finish and dimensional accuracy.

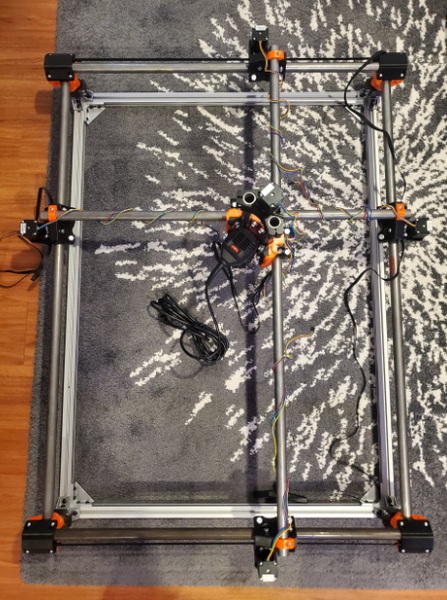

Case Study 2: DIY 3D Printer Frame

An avid 3D printing enthusiast built a custom 3D printer frame using 3030 aluminum extrusion. The modularity of the extrusion allowed them to easily add and modify components, creating a printer that perfectly met their specific needs.

Conclusion

The use of 3030 aluminum extrusion in 3D printer magnetic extruders offers numerous benefits, including structural stability, modularity, heat dissipation, and design flexibility. By providing a robust and customizable foundation, 3030 aluminum extrusion enhances the performance and reliability of magnetic extruders, leading to higher-quality 3D prints. Whether you are a seasoned 3D printer enthusiast or a professional engineer, incorporating 3030 aluminum extrusion into your magnetic extruder design is a worthwhile investment.

Frequently Asked Questions (FAQ)

Q1: What is 3030 aluminum extrusion?

3030 aluminum extrusion is an aluminum profile with a cross-section of approximately 30mm x 30mm, created by forcing heated aluminum through a die to achieve a specific shape[3]. It's known for its strength, lightweight properties, and versatility[1].

Q2: What are the main benefits of using 3030 aluminum extrusion in a 3D printer?

The primary benefits include structural stability, modularity, heat dissipation, and design flexibility. It provides a robust foundation for components, simplifies assembly, and allows for easy customization[1].

Q3: How does 3030 aluminum extrusion contribute to better print quality?

The rigidity and vibration-dampening properties of 3030 aluminum extrusion help maintain a stable and consistent filament flow, resulting in smoother surfaces and more accurate details in printed parts.

Q4: Can 3030 aluminum extrusion be easily customized for specific 3D printer designs?

Yes, aluminum extrusion can be easily cut, drilled, and machined to meet specific design requirements. This is particularly useful for magnetic extruders, where precise alignment and mounting of magnetic components are critical[1].

Q5: Is 3030 aluminum extrusion a cost-effective material for building 3D printers?

While it may have a higher initial cost compared to other materials like steel or plastic, the durability and long-lasting performance of aluminum extrusion make it a cost-effective choice in the long run, reducing maintenance and replacement costs[1].

Citations:

[1] https://www.aliexpress.com/w/wholesale-3030-aluminium-extrusion.html

[2] https://makerworld.com/en/models/632814

[3] https://kdmfab.com/aluminum-extrusion/

[4] https://makerworld.com/en/models/231227

[5] https://www.youtube.com/watch?v=tmXloDAvArI

[6] https://mostelectronic.com/shop/cnc-3d-printer-parts/aluminium-profile-extrusion-3030/

[7] https://www.reddit.com/r/3Dprinting/comments/icgrtv/why_does_everyone_use_2020_and_3030_extrusion/

[8] https://www.aliexpress.com/i/32908437083.html

[9] https://vitomfg.com/blog/advantages-of-wide-groove-width-in-industrial-aluminum-extrusion/

[10] https://www.youtube.com/watch?v=hHF7v9b7HjE

[11] https://www.yeggi.com/q/slider+aluminium+3030/

[12] https://forum.v1e.com/t/portable-primo-24in-x-36in-pnw-3030-aluminum-extrusion-adaptor/31905

[13] https://aec.org/features-benefits

[14] https://www.yeggi.com/q/extrusion+30x30mm/

[15] https://ampere-electronics.com/product/3030-t-slot-aluminum-profile-extrusion-1m-silver-anodized/

[16] https://reprap.org/forum/read.php

[17] https://www.aliexpress.com/i/32908832161.html

[18] https://langlealuminium.en.made-in-china.com/product/EernsJjbvUIf/China-3030-T-Slot-Industrial-Aluminium-Extrusion-Profile-6063-Aluminium-Profile.html

[19] https://kdmfab.com/tr/aluminum-extrusion/

[20] https://caribou3d.com/en/caribou-3d-printers/989-caribouidex.html

[21] https://www.alibaba.com/product-detail/Aluminum-Profile-3030-Aluminum-Extrusion-Profile_1600370658183.html

[22] https://www.alibaba.com/product-detail/Black-Aluminum-Profile-Aluminum-Extrusion-Profile_60802374327.html

[23] https://www.alibaba.com/product-detail/Black-Aluminum-Profile-Prusa-I3-MK3_60837181434.html

[24] https://www.alibaba.com/product-detail/China-t-slot-track-3030-industrial_1600930790060.html

[25] https://m.aliexpress.com/wholesale/3030-aluminum-extrusion.html?browser_id=e50d964760e9466aa1d39d1a3a53d595&m_page_id=187e40efc0017d0dc62f16249cb6a31b0d821ea902

[26] https://www.printables.com/model/312162-2020-2040-3030-3060-aluminum-extrusions/related

[27] https://www.thingiverse.com/thing:3039545

[28] https://www.matara.com/product/aluminium-extrusion/aluminium-profile-accessories/door-and-window-elements/latches-and-locks/magnet-catch-3030-profile-3030-door-frame-set/

[29] https://www.printables.com/model/74948-3030-bosch-b-type-aluminium-extrusion-zip-tie-anch

[30] https://sdkemet.en.made-in-china.com/product/TmsrXQwSZZWt/China-3030-Aluminum-Extrusion-Profile-Frame-T-Slot-Connecting-Accessories-for-Industrial-Usage.html

[31] https://co.pinterest.com/pin/910571618728510735/

[32] https://www.aliexpress.com/p/video/detail.html?itemId=1005007378312750

[33] https://www.printables.com/model/138407-3030-extrusion

[34] https://www.alibaba.com/product-detail/30-30-customized-aluminum-profile-display_1601113591203.html

[35] https://www.reddit.com/r/Reprap/comments/46a5v7/where_can_i_buy_3030_aluminum_extrusions/

[36] https://www.alibaba.com/showroom/3d-printer-extruded-aluminum.html