Content Menu

● Introduction

● Understanding Aluminum Corner Brackets

● Key Features to Consider

● Types of Extrusion Brackets

● Choosing the Right Bracket for Your Project

● Installation Tips

● Conclusion

● Related Questions

>> 1. What are the advantages of using aluminum extrusion corner brackets?

>> 2. How do I determine the load capacity of T-slot brackets?

>> 3. Can T-slot brackets be used in outdoor applications?

>> 4. Are there any specific tools required for installing aluminum corner brackets?

>> 5. How can I ensure the stability of my structure after installing T-slot brackets?

Introduction

Aluminum extrusion corner brackets, particularly T-slot brackets, play a crucial role in ensuring the structural integrity of various projects, from simple DIY tasks to complex industrial applications. These brackets are designed to provide strong, reliable connections between aluminum extrusions, which are widely used in construction, manufacturing, and engineering. In this article, we will explore the importance of T-slot brackets, their features, types, and how to choose the right ones for your needs. We will also provide installation tips and conclude with a summary of key points.

Understanding Aluminum Corner Brackets

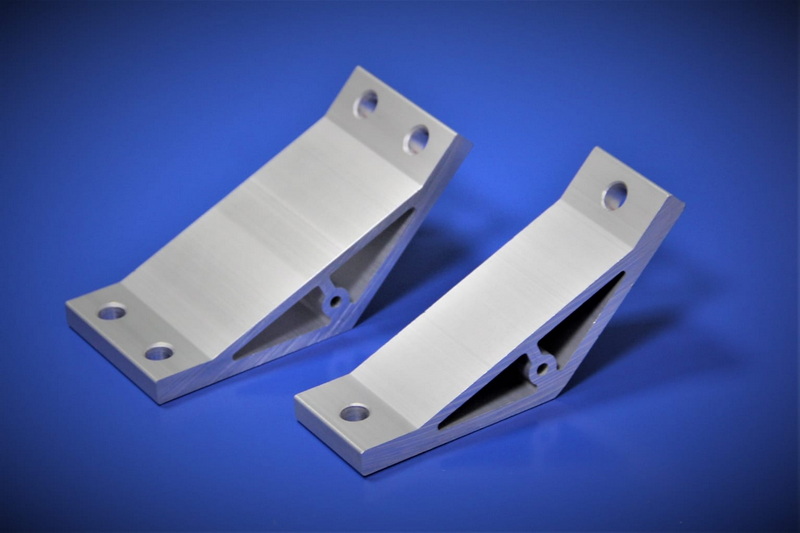

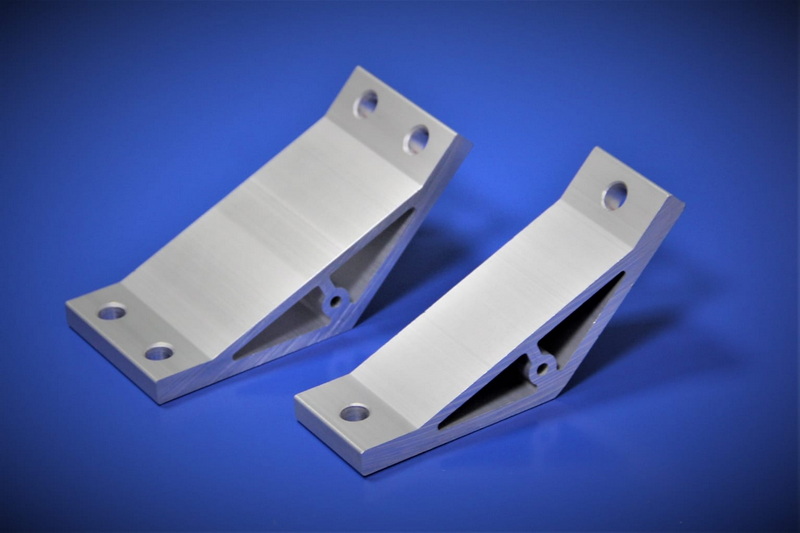

Aluminum corner brackets are essential components in the assembly of structures made from aluminum extrusions. They are designed to connect two or more pieces of aluminum at a right angle, providing stability and support. T-slot brackets, a specific type of aluminum corner bracket, are particularly popular due to their versatility and ease of use. These brackets feature a T-shaped slot that allows for easy attachment to aluminum extrusions, making them ideal for a wide range of applications.

T-slot brackets are commonly used in various industries, including manufacturing, robotics, and construction. They are often found in the assembly of frames, workstations, and machinery. The ability to create strong, rigid connections with T-slot brackets is essential for maintaining the structural integrity of these assemblies.

Key Features to Consider

When selecting aluminum corner brackets, several key features should be considered to ensure you choose the right product for your project.

Material Quality and Durability

Aluminum is known for its lightweight yet strong properties, making it an ideal material for corner brackets. High-quality aluminum brackets are resistant to corrosion and can withstand various environmental conditions, ensuring long-lasting performance.

Load Capacity and Weight Ratings

Different projects require different load capacities. It is essential to choose T-slot brackets that can support the weight of the materials being used. Always check the manufacturer's specifications for load ratings to ensure the brackets will meet your project's demands.

Design Variations

T-slot brackets come in various designs, including adjustable and fixed options. Adjustable brackets allow for flexibility in assembly, making it easier to achieve precise angles and alignments. Fixed brackets, on the other hand, provide a more rigid connection, which may be necessary for certain applications.

Types of Extrusion Brackets

There are several types of aluminum extrusion brackets available, each designed for specific applications. Understanding these types can help you make an informed decision when selecting the right bracket for your project.

T-Slot Brackets

T-slot brackets are designed to fit into the T-slots of aluminum extrusions, allowing for easy attachment and adjustment. They are available in various sizes and configurations, making them suitable for a wide range of applications. T-slot brackets are essential for creating strong, stable connections in frames and structures.

Heavy Duty Corner Brackets

For projects that require additional strength, heavy-duty corner brackets are an excellent choice. These brackets are made from thicker aluminum and are designed to support heavier loads. They are ideal for industrial applications where structural integrity is paramount.

Corner Bracket Kits

Many manufacturers offer corner bracket kits that include multiple brackets and fasteners. These kits are convenient for those who need to complete a project quickly and efficiently. They often come with all the necessary components to assemble a sturdy structure.

Choosing the Right Bracket for Your Project

Selecting the right T-slot bracket for your project involves considering several factors. Here are some tips to help you make the best choice:

Project Requirements

Assess the specific requirements of your project. Consider the weight of the materials you will be using and the overall design of the structure. This will help you determine the type and size of brackets needed.

Environmental Conditions

If your project will be exposed to harsh environmental conditions, such as moisture or extreme temperatures, choose brackets made from corrosion-resistant materials. Anodized aluminum brackets are an excellent option for outdoor applications.

Budget

While it is essential to choose high-quality brackets, it is also important to consider your budget. Compare prices from different manufacturers and look for kits that offer good value for money without compromising on quality.

Installation Tips

Proper installation of aluminum corner brackets is crucial for ensuring the structural integrity of your project. Here are some step-by-step tips to help you install T-slot brackets effectively:

1. Gather Your Tools

Before starting the installation, gather all necessary tools, including a drill, screws, and a level. Having everything on hand will make the process smoother.

2. Prepare the Aluminum Extrusions

Ensure that the aluminum extrusions are cut to the correct lengths and that the ends are clean and free of debris. This will help create a secure connection.

3. Position the Brackets

Place the T-slot brackets in the desired position on the aluminum extrusions. Use a level to ensure that everything is aligned correctly.

4. Secure the Brackets

Using the appropriate screws, secure the brackets to the aluminum extrusions. Be careful not to overtighten, as this can damage the aluminum.

5. Check for Stability

Once all brackets are installed, check the stability of the structure. Make any necessary adjustments to ensure everything is secure and aligned.

Conclusion

T-slot brackets are essential components for maintaining the structural integrity of projects involving aluminum extrusions. Their versatility, strength, and ease of installation make them a popular choice in various industries. By understanding the different types of brackets available and considering key features such as material quality, load capacity, and design variations, you can select the right T-slot brackets for your specific needs. Proper installation is crucial for ensuring the stability and longevity of your project, so be sure to follow best practices when assembling your structure.

Related Questions

1. What are the advantages of using aluminum extrusion corner brackets?

Aluminum extrusion corner brackets offer several advantages, including lightweight construction, corrosion resistance, and ease of installation. They provide strong connections that enhance the structural integrity of various projects.

2. How do I determine the load capacity of T-slot brackets?

To determine the load capacity of T-slot brackets, refer to the manufacturer's specifications. These specifications typically include weight ratings based on the bracket's design and material.

3. Can T-slot brackets be used in outdoor applications?

Yes, T-slot brackets can be used in outdoor applications, especially if they are made from corrosion-resistant materials such as anodized aluminum. This ensures durability in harsh environmental conditions.

4. Are there any specific tools required for installing aluminum corner brackets?

While basic tools such as a drill and screws are necessary, it is also helpful to have a level and measuring tape to ensure accurate alignment and positioning during installation.

5. How can I ensure the stability of my structure after installing T-slot brackets?

To ensure stability, regularly check the connections and make adjustments as needed. Additionally, consider using heavy-duty brackets for projects that require extra support, and always follow proper installation techniques.