Content Menu

● Introduction to Aluminium Extrusion

>> Aluminium Extrusion Process

● Leading Aluminium Extrusion Equipment Manufacturers

>> 1. LONGKOU MAT ALUMINUM CO., LTD.

>> 2. Impol

>> 3. Hydro Extruded Solutions

>> 4. Sinpower Aluminium

>> 5. Orgbar Aluminium Ltd

● Applications of Aluminium Extrusion Equipment

>> 1. Construction Industry

>> 2. Automotive Industry

>> 3. Aerospace Industry

>> 4. Electrical and Electronics

>> 5. Medical and Medical Equipment

● Advantages of Aluminium Extrusion

● Major Aluminium Extrusion Companies

● Aluminium Extrusion Equipment Suppliers

● Future Trends in Aluminium Extrusion

● Conclusion

● FAQs

>> 1. What types of industries use aluminium extrusion equipment?

>> 2. How does the aluminium extrusion process work?

>> 3. What are the advantages of using aluminium extrusion equipment?

>> 4. What are some common applications of aluminium extrusions?

>> 5. How do manufacturers ensure the quality of aluminium extrusions?

● Citations:

Aluminium extrusion is a widely used manufacturing process that involves forcing aluminium through a die to create complex cross-sectional profiles. This technique is crucial in various industries, including construction, automotive, aerospace, and electronics. The demand for high-quality aluminium extrusion equipment has led to the emergence of several leading manufacturers specializing in this field. In this article, we will explore the top aluminium extrusion equipment manufacturers and delve into the intricacies of their products and services.

Introduction to Aluminium Extrusion

Aluminium extrusion is a versatile process that allows for the creation of diverse shapes and profiles, making it an essential component in many industrial applications. The process involves heating aluminium billets to a high temperature and then pushing them through a die to form the desired shape. This method is cost-effective and efficient, allowing for the production of complex profiles with precision.

Aluminium Extrusion Process

The aluminium extrusion process can be broken down into several key steps:

1. Billet Preparation: Aluminium billets are cut into specific lengths to ensure uniformity in the extruded product.

2. Heating: The billets are heated in a furnace to make them malleable.

3. Extrusion: The heated billet is then pushed through a die using a hydraulic press.

4. Cooling: The extruded profile is cooled to achieve the desired mechanical properties.

5. Finishing: The final step involves various finishing processes such as cutting, machining, or anodizing.

Leading Aluminium Extrusion Equipment Manufacturers

Several companies stand out as leading manufacturers of aluminium extrusion equipment, providing innovative solutions and high-quality machinery.

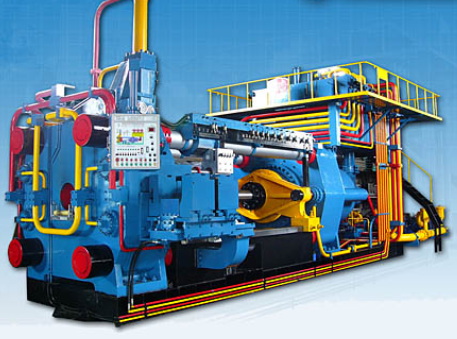

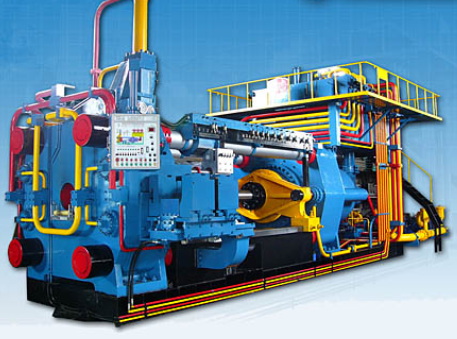

1. LONGKOU MAT ALUMINUM CO., LTD.

LONGKOU MAT ALUMINUM CO., LTD. is renowned for its high-quality aluminium extrusion machines, which are designed using the latest technology to ensure top performance and excellent results. Their machines are ideal for producing precise aluminium profiles used in industries such as construction, transportation, and aerospace.

2. Impol

Impol is another significant player in the aluminium extrusion industry, offering a range of extrusion presses with varying power levels. Their equipment is designed to meet specific customer requirements, ensuring flexibility and efficiency in production.

3. Hydro Extruded Solutions

Hydro Extruded Solutions, part of Norsk Hydro ASA, is a global leader in aluminium extrusion solutions. They provide comprehensive services from design to manufacturing, offering a wide range of extruded profiles used in various industries.

4. Sinpower Aluminium

Sinpower Aluminium, based in China, specializes in designing and producing a wide range of aluminum extrusion products, including t-slot profiles, heat sinks, and custom aluminum profiles. With 25 extrusion lines and an annual production capacity exceeding 40,000 tons, the company ensures high-quality aluminum extrusions using various alloy materials[1].

5. Orgbar Aluminium Ltd

Orgbar Aluminium, located in the UK, offers bespoke extrusions and emphasizes understanding customer requirements to provide cost-effective solutions. They ensure excellent manufacturing and logistics support for various aluminium projects[1].

Applications of Aluminium Extrusion Equipment

Aluminium extrusion equipment is used across multiple sectors due to its versatility and the lightweight yet durable nature of aluminium.

1. Construction Industry

Aluminium extrusions are widely used in building frames, windows, and doors due to their corrosion resistance and strength. They are also used in architectural features such as facades and roofing systems.

2. Automotive Industry

In the automotive sector, aluminium extrusions are used for vehicle components such as engine blocks and chassis parts, benefiting from aluminium's lightweight properties. This helps in reducing vehicle weight, which can improve fuel efficiency and performance.

3. Aerospace Industry

The aerospace industry utilizes aluminium extrusions for aircraft components due to their high strength-to-weight ratio and corrosion resistance. These properties are crucial for ensuring the structural integrity and safety of aircraft.

4. Electrical and Electronics

Aluminium extrusions are vital in creating protective enclosures for electronic devices, offering mechanical protection and customization for various applications, including computers and telecommunications. Additionally, aluminium's excellent thermal conductivity makes it ideal for heat sinks, dissipating heat from components to prevent overheating[4].

5. Medical and Medical Equipment

Aluminium extrusions play a crucial role in the medical field, offering strong yet lightweight solutions for a wide range of applications. They are used to create durable and customizable frames for diagnostic machines like X-rays and MRI scanners, as well as for surgical tools and hospital equipment[4].

Advantages of Aluminium Extrusion

The advantages of aluminium extrusion include:

- Flexibility in Design: Aluminum extrusion enables the production of elaborate and sophisticated geometries that conventional manufacturing processes may find challenging[5].

- Lightweight and Durable: Aluminum is naturally lightweight; therefore, extruded items are excellent for applications where weight is an issue. They are also durable, corrosion-resistant, and low-maintenance[6].

- Cost Effectiveness: Aluminum extrusion's adaptability eliminates the need for auxiliary processes, lowering manufacturing costs. The method also produces less waste, which aligns with efficient and economical production methods[5].

- Rapid Prototyping: Aluminum extrusion makes rapid prototyping possible, which also has short manufacturing lead times. As a result, producers may quickly iterate designs and release items to the market[5].

Major Aluminium Extrusion Companies

Some of the biggest aluminium extrusion companies globally include:

- Norsk Hydro ASA: Known for its innovative solutions and commitment to sustainability[2].

- Constellium SE: Offers advanced aluminum products for sectors like automotive and aerospace[2].

- China Hongqiao Group Limited: The largest aluminium extrusion company in China, focusing on technological advancements[2].

- Alcoa Corporation: Provides a wide range of extruded products with precision and durability[2].

Aluminium Extrusion Equipment Suppliers

Several companies specialize in supplying equipment for aluminium extrusion, including:

- Presezzi Extrusion Group: Offers comprehensive solutions for extrusion processes[3].

- SMS group GmbH: Known for its advanced machinery and automation systems[3].

- Danieli USA: Provides high-quality extrusion equipment and process control systems[3].

Future Trends in Aluminium Extrusion

The future of aluminium extrusion is promising, with ongoing advancements in technology and sustainability. Manufacturers are focusing on developing more efficient processes and products that meet the growing demand for lightweight yet durable materials across various industries.

Conclusion

In conclusion, the leading aluminium extrusion equipment manufacturers play a crucial role in supporting various industries by providing high-quality machinery and innovative solutions. Companies like LONGKOU MAT ALUMINUM CO., LTD., Impol, Hydro Extruded Solutions, Sinpower Aluminium, and Orgbar Aluminium Ltd are at the forefront of this industry, offering advanced equipment that meets the diverse needs of their clients.

FAQs

1. What types of industries use aluminium extrusion equipment?

Aluminium extrusion equipment is used in a variety of industries including construction, automotive, aerospace, electronics, and medical equipment. These industries benefit from the lightweight yet durable nature of aluminium.

2. How does the aluminium extrusion process work?

The aluminium extrusion process involves heating aluminium billets and pushing them through a die to form specific profiles. The process includes heating, extrusion, cooling, and finishing stages.

3. What are the advantages of using aluminium extrusion equipment?

The advantages include the ability to produce complex profiles with precision, cost-effectiveness, and the versatility of aluminium in various applications. Additionally, aluminium extrusions are lightweight, durable, and corrosion-resistant.

4. What are some common applications of aluminium extrusions?

Common applications include building frames, vehicle components, aircraft parts, electronic enclosures, and medical equipment. Aluminium extrusions are valued for their strength, corrosion resistance, and lightweight properties.

5. How do manufacturers ensure the quality of aluminium extrusions?

Manufacturers ensure quality through rigorous inspection methods, adherence to industry standards, and the use of advanced machinery that maintains precise tolerances and surface finishes.

Citations:

[1] https://ensun.io/search/aluminium-extrusion

[2] https://www.indexbox.io/search/biggest-aluminium-extrusion-companies-in-the-world/

[3] https://www.lightmetalage.com/wp-content/uploads/2024/04/LMA_APR_2024_directory.pdf

[4] https://eleanoraluminium.com/solutions/electrical-and-medical-applications/

[5] https://flowstore.com/understand-aluminium-extrusion-modern-manufacturing/

[6] https://www.renxin-precision.com/blogs-detail/-28

[7] https://us.metoree.com/categories/100086/

[8] https://www.linkedin.com/pulse/7-common-applications-industrial-aluminum

[9] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[10] https://proleantech.com/aluminum-extrusion-explained/

[11] https://proax.ca/en/blog/post/aluminum-extrusion-manufacturing-applications

[12] https://www.belcoind.com/the-benefits-of-designing-with-aluminum-extrusions/

[13] https://www.iqsdirectory.com/aluminum-extrusions/

[14] https://www.made-in-china.com/products-search/hot-china-products/Aluminum_Extrusion_Machine.html

[15] https://www.sourcifychina.com/top-aluminium-extrusion-manufacturing-compare/

[16] https://www.iqsdirectory.com/aluminum-extruders/

[17] https://www.shengxinglobal.com/blog/aluminum-extrusion-profiles-the-definitive-guide-2025.html

[18] https://www.fonnovaluminium.com/top-10-aluminum-extrusion-manufacturers-in-the-united-states.html

[19] https://www.instagram.com/theindustryoutlook/p/DFsNRWXvLzR/

[20] https://www.linkedin.com/pulse/top-5-most-popular-aluminum-extrusion-equipment-2021-chauvette

[21] https://www.weiye-aluminium.com/what-are-the-most-popular-aluminum-extrusion-profiles-in-2025.html

[22] https://www.theindustryoutlook.com/manufacturing/ranking/top-10-aluminium-extrusion-manufacturers-2023-rid-848.html

[23] https://www.nextmsc.com/report/aluminium-extrusion-market

[24] https://zjaluminum-cnc.com/top-10-aluminum-extrusion-product-manufacturers-from-china/

[25] https://amcaluminum.ph/advantages-of-aluminum-extrusion-products/

[26] https://tonitechnik.com/application-information-aluminium-extrusion-industry/

[27] https://simmal.com/the-advantages-of-aluminium-extrusion-in-manufacturing/

[28] https://www.howardprecision.com/the-advantages-of-aluminum-extruded-products/

[29] https://www.wileymetal.com/five-common-applications-of-aluminum-extrusion/

[30] https://aec.org/features-benefits

[31] https://simmal.com/aluminium-extrusion-vs-other-metals/

[32] https://www.aluminiumalca.com/blog/exploring-the-advantages-and-applications-of-aluminum-extrusion/1/

[33] https://kimsen.vn/the-benefits-of-aluminum-extrusion-for-sustainable-manufacturing-ne142.html

[34] https://www.gabrian.com/what-are-aluminum-extrusions-used-for/

[35] https://nationalindustries.world/2025/01/02/the-future-of-aluminum-how-extrusion-technology-is-transforming-industries/

[36] https://members.aec.org/page/extrusion-applications-machinery

[37] https://www.alcircle.com/news/top-five-aluminium-extrusion-companies-in-the-world-26837

[38] https://www.alcirclebiz.com/blogs/top-aluminum-extrusion-players-in-china

[39] https://www.mordorintelligence.com/industry-reports/automotive-aluminium-extrusion-market/companies

[40] https://www.zetwerk.com/resources/knowledge-base/aluminum-extrusions/top-aluminum-extrusion-suppliers-in-the-usa/