Content Menu

● Introduction

● Understanding Silicone Rubber Extrusion Machinery

>> Common Extrusion Methods

● Key Criteria for Selecting the Best Manufacturer

● Leading Global Manufacturers of Silicone Rubber Extrusion Equipment

>> 1. Zhejiang Baina Rubber & Plastic Equipment Co., Ltd.

>> 2. Dongguan Yunxin Machinery Manufacturing Co., Ltd.

>> 3. Qingdao Create Trust Industry Co., Ltd.

>> 4. Qingdao Sea King Machinery Co., Ltd.

>> 5. Sheng-an Plastic Machinery Co., Ltd.

● Regional Leaders and Notable Suppliers

>> North America

>> Europe

>> Asia

● Customization, Technology, and Support

>> Customization

>> Technological Innovation

>> After-Sales Support

● Industry Applications and Trends

>> Emerging Trends

● Conclusion

● FAQ

>> 1. What factors should I consider when choosing a silicone rubber extrusion machinery manufacturer?

>> 2. Which regions are known for leading silicone rubber extrusion machinery manufacturers?

>> 3. How important is after-sales support for silicone rubber extrusion machinery?

>> 4. Can I get customized silicone rubber extrusion machinery for unique profiles?

>> 5. What are the latest technological trends in silicone rubber extrusion machinery?

● Citations:

Silicone rubber extrusion machinery is a cornerstone of modern manufacturing, enabling the production of high-performance seals, gaskets, tubing, and custom profiles for industries ranging from automotive to electronics and healthcare. As demand for precision, durability, and customization grows, selecting the right manufacturer for silicone rubber extrusion equipment becomes critical. This comprehensive guide explores the leading manufacturers, their specialties, and what sets them apart in the competitive landscape of silicone rubber extrusion machinery.

Introduction

Silicone rubber extrusion machinery has revolutionized the way manufacturers produce flexible, durable, and chemically resistant components. From automotive weatherstripping to medical tubing, the versatility of silicone rubber and the precision of modern extrusion equipment have made this technology indispensable. However, the quality of the final product hinges on the capabilities of the extrusion machinery and the expertise of the manufacturer.

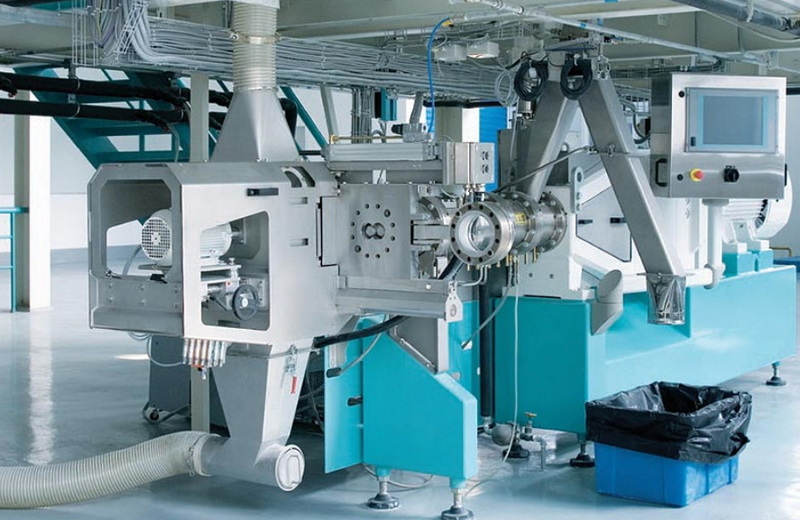

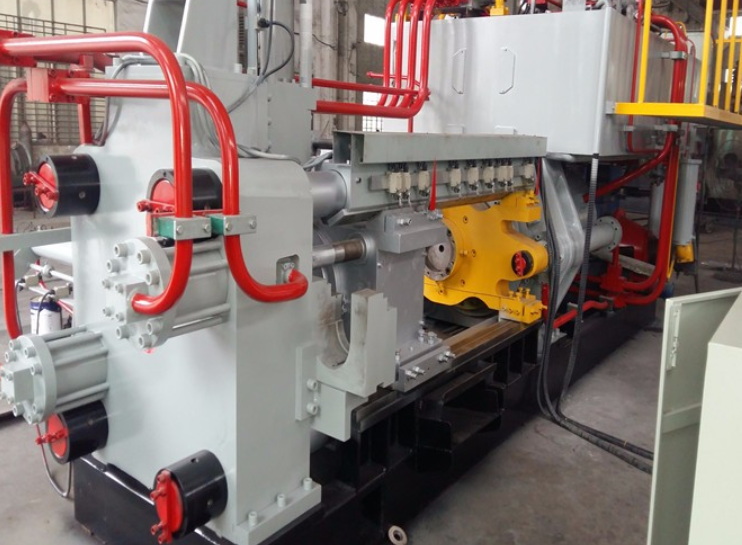

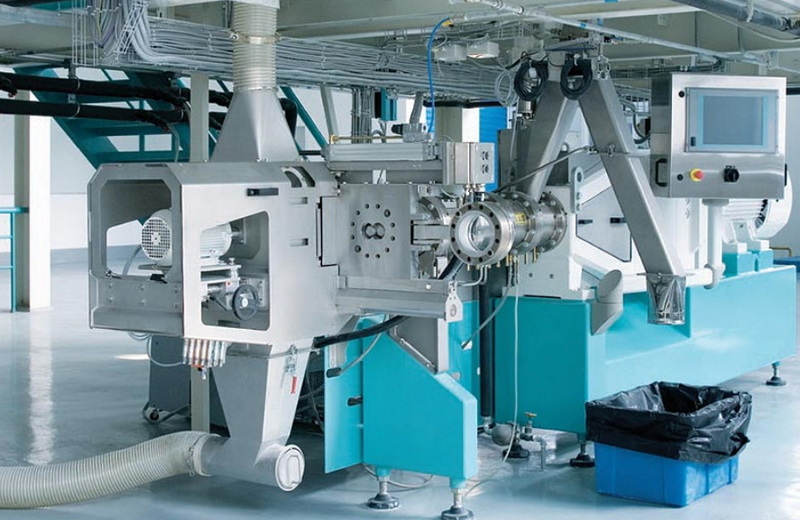

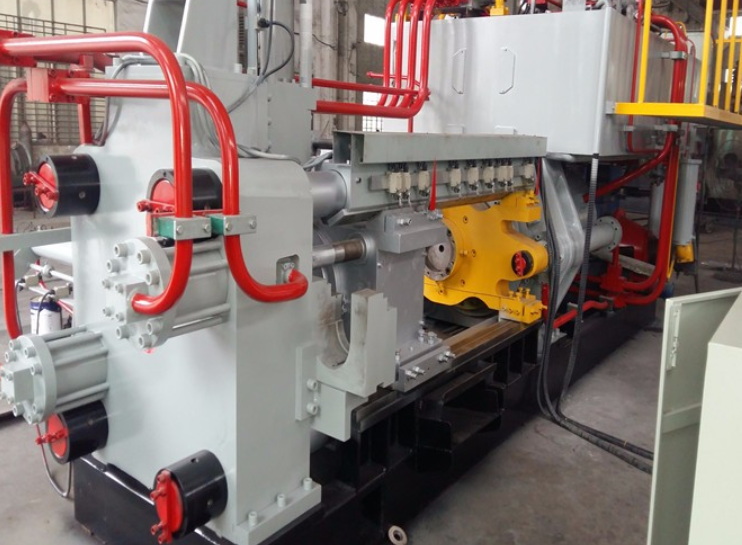

Understanding Silicone Rubber Extrusion Machinery

Silicone rubber extrusion machinery is designed to process raw silicone compounds into continuous profiles with precise cross-sectional shapes. The process involves forcing uncured silicone through a die, followed by curing (vulcanization) to set the final shape and properties. The machinery typically includes:

- Feed and Mixing Systems: For consistent material preparation.

- Extruders: The core unit, which pushes the silicone through the die.

- Curing Systems: Such as hot air, microwave, or salt bath vulcanization.

- Cutting and Finishing Equipment: For sizing and post-processing.

Common Extrusion Methods

- Liquid Injection Molding (LIM): Suitable for complex, small to medium-sized parts.

- Compression Molding: Ideal for low-volume, high-precision parts.

- Transfer Molding: Used for medium to high-volume production with complex geometries[1].

Key Criteria for Selecting the Best Manufacturer

Choosing the right manufacturer for silicone rubber extrusion machinery involves evaluating several critical factors:

- Quality and Precision: Machinery must deliver consistent, high-quality extrusions.

- Customization Capabilities: Ability to tailor equipment for specific profiles or applications.

- Technological Innovation: Advanced features such as automation, energy efficiency, and digital controls.

- After-Sales Support: Training, maintenance, and spare parts availability.

- Certifications: Compliance with international standards (ISO, CE, etc.).

- Reputation and Experience: Proven track record in the industry.

Leading Global Manufacturers of Silicone Rubber Extrusion Equipment

1. Zhejiang Baina Rubber & Plastic Equipment Co., Ltd.

A leading Chinese manufacturer specializing in rubber and silicone extrusion equipment, Baina offers a wide range of machinery including extruders, microwave vulcanization lines, and salt bath vulcanization systems. Their equipment is widely used for producing silicone hoses, seals, and profiles, and is recognized for its reliability and advanced technology[2].

2. Dongguan Yunxin Machinery Manufacturing Co., Ltd.

Renowned for its comprehensive range of silicone rubber extrusion machinery, Dongguan Yunxin provides solutions for mixing, extrusion, vulcanization, and hot press molding. Their focus on innovation and customization has made them a preferred supplier for both domestic and international clients[2].

3. Qingdao Create Trust Industry Co., Ltd.

This manufacturer is known for its robust rubber extruders, kneaders, calenders, and vulcanizing presses. Their silicone rubber extrusion machinery is used extensively in the automotive, construction, and electronics sectors, offering high output and precision[2].

4. Qingdao Sea King Machinery Co., Ltd.

Sea King specializes in rubber mixing, extrusion, and vulcanization equipment. Their silicone rubber extrusion lines are designed for high-volume production and are praised for their durability and ease of maintenance[2].

5. Sheng-an Plastic Machinery Co., Ltd.

Sheng-an offers industrial tube and profile extrusion equipment, including specialized solutions for silicone rubber. Their machinery is known for its adaptability and efficiency in producing complex profiles[2].

Regional Leaders and Notable Suppliers

North America

- GSH Industries, Inc. (USA): Offers a full suite of rubber extrusion machinery and is known for its ability to produce intricate silicone profiles for demanding applications[1][3][6].

- National Rubber Corp. (USA): Focuses on quality, consistency, and rapid delivery, with expertise in custom silicone extrusion solutions[1][6].

- Aero Rubber Company, Inc. (USA): Provides high-quality extruded rubber products, including silicone, with a reputation for precision and customer service[3][4].

- Trim-Lok, Inc. (USA): Specializes in rubber trim and seal products, with a strong emphasis on silicone extrusion for automotive and industrial uses[6].

Europe

- Advanced Materials (UK): A market leader in silicone rubber extrusion, Advanced Materials boasts over 30 years of experience, in-house tooling, and a reputation for quality and precision. They offer rapid quotations, traceability, and regulatory compliance, making them a trusted partner for custom and standard extrusions[5].

- Seals+Direct Ltd (UK): Provides a wide range of silicone and rubber extrusion products, focusing on seals and gaskets for marine, automotive, and industrial applications[6].

Asia

- Jinan Brushidea Industry Technology Co., Ltd. (China): Supplies a variety of silicone rubber extrusion machinery, with a focus on innovation and export quality[2].

- Dongguan Kesheng Intelligent Equipment Technology Co., Ltd. (China): Known for intelligent automation and advanced extrusion solutions[2].

Customization, Technology, and Support

Customization

Leading manufacturers offer extensive customization options, from die design to material selection and process integration. For example, Advanced Materials in the UK provides in-house tooling for both standard and bespoke profiles, ensuring fast turnaround and cost-effective solutions[5].

Technological Innovation

Modern silicone rubber extrusion machinery incorporates features such as:

- Automated Controls: For precise temperature, pressure, and speed regulation.

- Energy-Efficient Heating: Including microwave and infrared curing systems.

- Integrated Quality Monitoring: Real-time measurement of profile dimensions and properties.

After-Sales Support

Top manufacturers provide comprehensive support, including:

- Training: For machine operators and maintenance staff.

- Spare Parts: Fast delivery of critical components.

- Remote Diagnostics: For troubleshooting and process optimization.

Industry Applications and Trends

Silicone rubber extrusion machinery is used across diverse industries:

- Automotive: Seals, gaskets, and hoses for engines and interiors.

- Medical: Tubing, seals, and custom profiles for devices and equipment.

- Electronics: Insulation, grommets, and protective covers.

- Construction: Weatherstripping, glazing seals, and expansion joints.

Emerging Trends

- Sustainability: Energy-efficient machinery and recyclable silicone compounds.

- Digitalization: Integration of IoT for predictive maintenance and process optimization.

- Miniaturization: Equipment capable of producing micro-extrusions for electronics and medical devices.

Conclusion

Selecting the best manufacturer for silicone rubber extrusion machinery requires careful consideration of quality, customization, technology, and support. Leading companies such as Zhejiang Baina, Dongguan Yunxin, Advanced Materials, and GSH Industries have established themselves as industry benchmarks through innovation, reliability, and customer-centric approaches. Whether your needs are standard or highly specialized, these manufacturers offer the expertise and equipment necessary to achieve superior results in silicone rubber extrusion.

FAQ

1. What factors should I consider when choosing a silicone rubber extrusion machinery manufacturer?

Consider the manufacturer's experience, customization capabilities, technological innovation, after-sales support, and compliance with international standards. Reputation and proven performance in your industry are also crucial[1][5][6].

2. Which regions are known for leading silicone rubber extrusion machinery manufacturers?

China, the United States, and the United Kingdom are home to many top manufacturers, with China leading in large-scale production and technological innovation, the US focusing on quality and customization, and the UK excelling in precision and regulatory compliance[2][5][6].

3. How important is after-sales support for silicone rubber extrusion machinery?

After-sales support is vital for maintaining equipment performance, minimizing downtime, and ensuring operator proficiency. Top manufacturers offer training, spare parts, and remote diagnostics to support their clients[5].

4. Can I get customized silicone rubber extrusion machinery for unique profiles?

Yes, leading manufacturers provide extensive customization options, including bespoke die design, material selection, and integration with existing production lines to meet specific application requirements[1][5][6].

5. What are the latest technological trends in silicone rubber extrusion machinery?

Key trends include automation, energy-efficient curing systems, digital controls, real-time quality monitoring, and the integration of IoT for predictive maintenance and process optimization[5][6].

Citations:

[1] https://extrudedrubber.net/silicone-extrusions/

[2] https://www.made-in-china.com/manufacturers/silicone-rubber-extrusion-machine.html

[3] https://www.iqsdirectory.com/silicone-extrusions/

[4] https://us.metoree.com/categories/101809/

[5] https://www.siliconerubberextrusions.co.uk

[6] https://seashorerubber.com/blog/top-10-rubber-extrusion-manufacturers-in-the-world/

[7] https://daextrusion.com/materials/silicone-extrusion/

[8] https://www.merefsa.com/en/news/new-complete-silicone-extrusion-line_pidNW5885f454.html

[9] https://cxrubbermachine.en.made-in-china.com/product/qyjmpcgbwFWZ/China-China-Top-Quality-Silicone-Rubber-Extruder-Silicone-Rubber-Extrusion-Line-with-Ce-ISO9001.html

[10] https://www.alibaba.com/showroom/rubber-extruder-machine.html

[11] https://extrudedrubber.net/rubber-extruders/

[12] https://www.justdial.com/india/Silicone-Rubber-Extrusion-Manufacturers

[13] https://www.chesmai.com/product-5059-silicone-extrusion-machine.html

[14] https://rubbermolding.org/silicone-rubber/

[15] https://extrudedrubber.net

[16] https://www.indiamart.com/proddetail/silicone-rubber-extrusion-machine-23896899512.html

[17] https://dir.indiamart.com/impcat/silicone-rubber-extrusions.html

[18] https://www.rubbermakingmachinery.com/sale-14178636-silicone-rubber-cold-feed-rubber-extruder-machine.html

[19] https://www.rubber-tools.com/top-extruder-rubber-china-factory-products-compare/

[20] https://www.vikingextrusions.co.uk/blog/viking-extrusions-transforming-the-silicone-rubber-industry/