Content Menu

● Introduction to Solar Aluminum Extruders

>> Benefits of Aluminum Extrusions in Solar Applications

● Applications of Solar Aluminum Extruders

>> Solar Industry

>>> Residential Solar Installations

>>> Commercial Solar Projects

>> Agricultural and Rural Areas

>> International Projects

● Innovations and Advancements

>> Cost-Effectiveness

● Conclusion

● FAQ

>> 1. What are the primary uses of solar aluminum extruders?

>> 2. What benefits do aluminum extrusions offer in solar applications?

>> 3. How do solar aluminum extruders contribute to cost-effectiveness in solar projects?

>> 4. What role do aluminum extrusions play in international solar projects?

>> 5. How do advancements in aluminum extrusion technology impact the solar industry?

● Citations:

The use of solar aluminum extruders has become increasingly prevalent across various industries, primarily due to their versatility, durability, and cost-effectiveness. Aluminum extrusions play a pivotal role in the solar industry, providing essential components for solar panel frames, mounting systems, and other structural elements. In this article, we will explore the diverse applications of solar aluminum extruders, their benefits, and how they contribute to the advancement of renewable energy technologies.

Introduction to Solar Aluminum Extruders

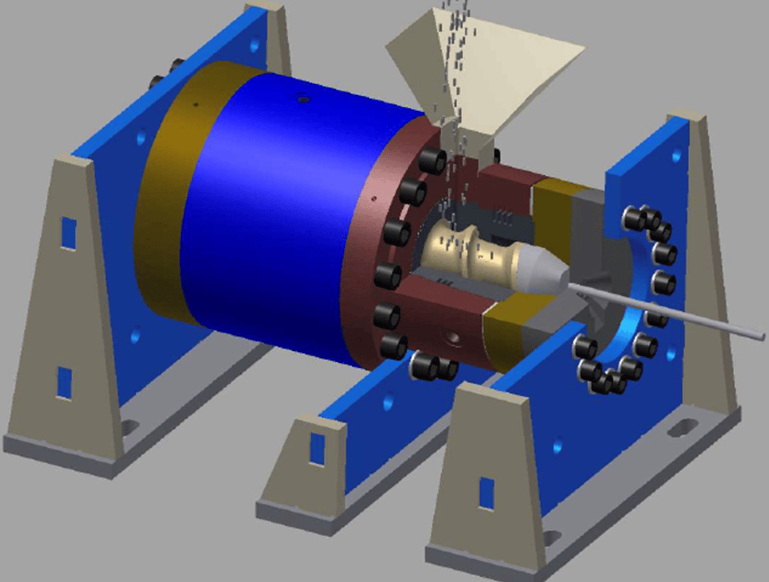

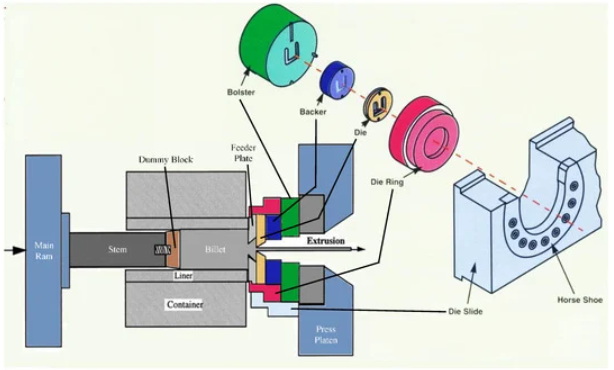

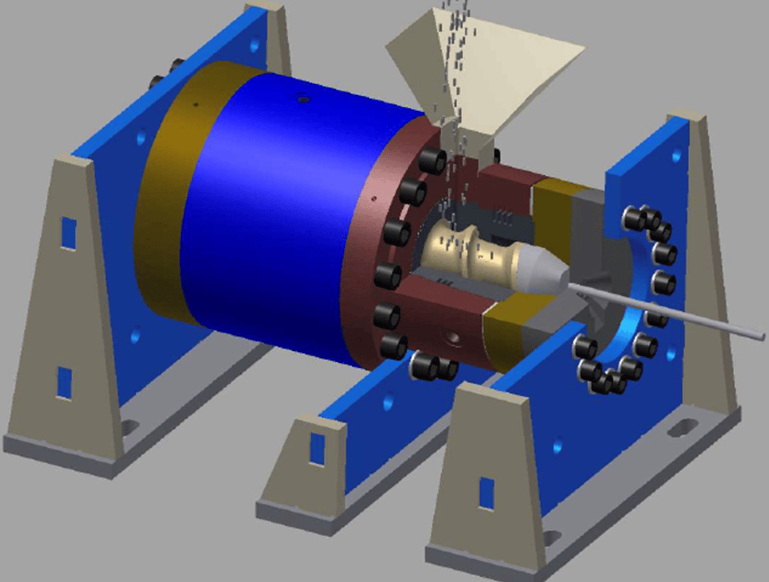

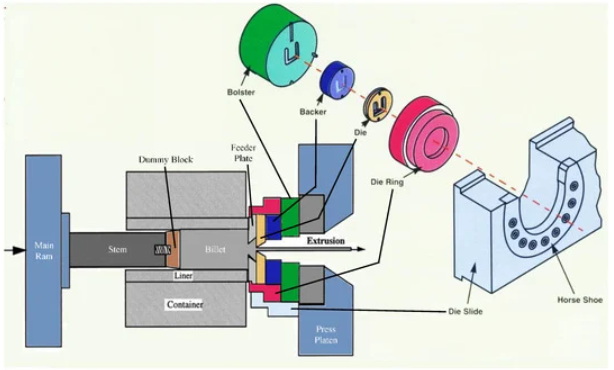

Solar aluminum extruders are specialized machines used to create aluminum profiles that are crucial for solar panel systems. These extrusions are made by heating aluminum billets and pushing them through a die to form customized shapes, which are essential for the construction of efficient and durable solar panel components.

Benefits of Aluminum Extrusions in Solar Applications

Aluminum extrusions offer several benefits that make them ideal for solar applications:

- Lightweight and Strong: Aluminum provides a high strength-to-weight ratio, making it perfect for supporting solar panels without adding excessive weight[1][2].

- Corrosion Resistance: Aluminum extrusions are inherently resistant to corrosion, ensuring long-lasting performance in harsh environmental conditions[1][5].

- Thermal Conductivity: Aluminum helps dissipate heat, maintaining optimal operational temperatures for solar panels and enhancing their efficiency[1].

- Recyclability: Aluminum is highly recyclable, supporting sustainable practices and reducing waste[1][3].

Applications of Solar Aluminum Extruders

Solar Industry

In the solar industry, aluminum extruders are primarily used for manufacturing solar panel frames and mounting systems. These extrusions provide a lightweight yet durable framework that protects photovoltaic cells from environmental factors like wind and hail[1][4].

Residential Solar Installations

Aluminum extrusions are commonly used in residential solar installations for framing and mounting systems. They offer stability, durability, and ease of installation, making them a popular choice for homeowners[1].

Commercial Solar Projects

Commercial solar projects utilize aluminum extrusions for their mounting and racking systems. These systems require reliability and efficiency to maximize energy production and minimize downtime[1].

Agricultural and Rural Areas

In agricultural and rural areas, aluminum extrusions are used in solar water pumping systems, providing a sustainable solution for irrigation and livestock watering. Their durability and low maintenance make them ideal for remote environments[1].

International Projects

Aluminum extrusions have been successfully implemented in various international solar projects, showcasing their global relevance and effectiveness. For example, large-scale solar farms in Spain have benefited from the lightweight and corrosion-resistant properties of aluminum extrusions[1].

Innovations and Advancements

Recent advancements in aluminum extrusion technology include more efficient extrusion processes, advanced alloy compositions, and greater customization and design flexibility. These innovations result in more precise and complex shapes, improved strength, corrosion resistance, and thermal conductivity[1].

Cost-Effectiveness

Aluminum extrusions contribute to the overall cost-effectiveness of solar projects through their excellent strength-to-weight ratio, reducing material and installation costs. Their design flexibility allows for optimized profiles that save on material use[1][3].

Conclusion

Solar aluminum extruders play a vital role in the solar industry by providing essential components for solar panel systems. Their versatility, durability, and cost-effectiveness make them a preferred choice for various solar applications. As technology continues to evolve, the use of solar aluminum extruders will remain crucial in advancing renewable energy solutions.

FAQ

1. What are the primary uses of solar aluminum extruders?

Solar aluminum extruders are primarily used for creating aluminum profiles that serve as frames, mounting systems, and other structural components for solar panels. These extrusions are essential for supporting and protecting photovoltaic cells while ensuring optimal positioning for sunlight exposure[1][4].

2. What benefits do aluminum extrusions offer in solar applications?

Aluminum extrusions offer several benefits, including a high strength-to-weight ratio, corrosion resistance, excellent thermal conductivity, and recyclability. These properties enhance the efficiency, durability, and sustainability of solar panel systems[1][3].

3. How do solar aluminum extruders contribute to cost-effectiveness in solar projects?

Solar aluminum extruders contribute to cost-effectiveness by providing lightweight yet durable components that reduce material and installation costs. Their design flexibility allows for optimized profiles that save on material use, and their recyclability provides end-of-life value[1][3].

4. What role do aluminum extrusions play in international solar projects?

Aluminum extrusions have been successfully implemented in various international solar projects, showcasing their global relevance and effectiveness. They are used in large-scale solar farms, benefiting from their lightweight and corrosion-resistant properties[1].

5. How do advancements in aluminum extrusion technology impact the solar industry?

Advancements in aluminum extrusion technology lead to more precise and complex shapes, improved strength, corrosion resistance, and thermal conductivity. These innovations enhance the efficiency, durability, and cost-effectiveness of solar energy systems, driving advancements in solar technology[1].

Citations:

[1] https://shop.machinemfg.com/how-are-aluminum-extrusions-used-in-the-solar-industry/

[2] https://www.goldapple-alu.com/case-studies-successful-applications-of-aluminum-extrusion-in-solar-panel-projects.html

[3] https://www.solarpowerworldonline.com/2011/10/study-says-aluminum-extrusions-are-better-for-solar-frame-structures/

[4] https://kimsen.vn/how-aluminum-extrusion-is-innovating-the-solar-energy-industry-nj91.html

[5] https://sinoextrud.com/aluminum-extrusion-solar-mounting/

[6] https://caod.oriprobe.com/issues/1899443/toc.htm

[7] https://www.kloecknermetals.com/blog/how-are-aluminum-extrusions-used-in-the-solar-industry/

[8] https://www.hydro.com/en/global/aluminium/products/extruded-profiles/aluminium-extrusions-in-use/aluminium-profiles-for-solar-mounting-systems/

[9] https://news.metal.com/newscontent/101761053/65-years-of-aluminum-extrusion-industry-in-china

[10] https://patents.google.com/patent/CN114097096A/ko