Content Menu

● Introduction to Conair Extrusion Equipment

>> Conair Extrusion Development & Testing Lab

● Industries Utilizing Conair Extrusion Equipment

>> 1. Automotive Industry

>> 2. Packaging Industry

>> 3. Medical Devices Industry

>> 4. Building and Construction Industry

● Benefits of Using Conair Extrusion Equipment

● Conair's ProfileMaster Equipment Line

● Conair's Role in Medical Manufacturing

● Conair's Extrusion Lab Capabilities

● Conclusion

● FAQs

>> 1. What types of industries primarily use Conair extrusion equipment?

>> 2. What are the key features of Conair's extrusion lab?

>> 3. How does Conair support the medical devices industry?

>> 4. What are the benefits of using Conair extrusion equipment?

>> 5. Where is Conair's extrusion lab located?

● Citations:

Conair extrusion equipment is widely used across various industries due to its versatility and efficiency in enhancing production processes. This article will delve into the primary industries that utilize Conair extrusion equipment, highlighting their applications and benefits.

Introduction to Conair Extrusion Equipment

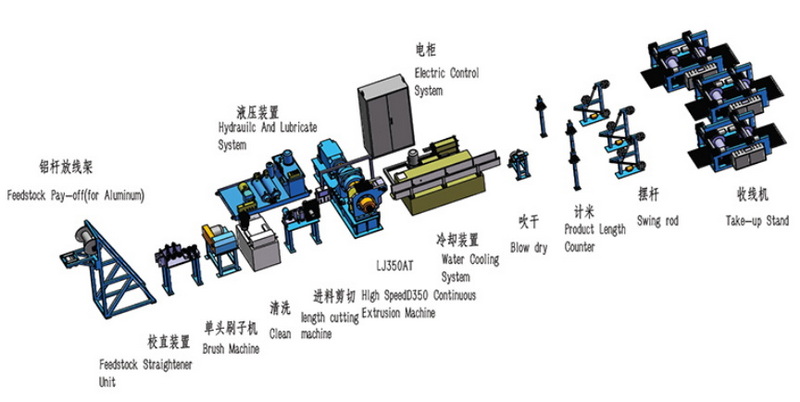

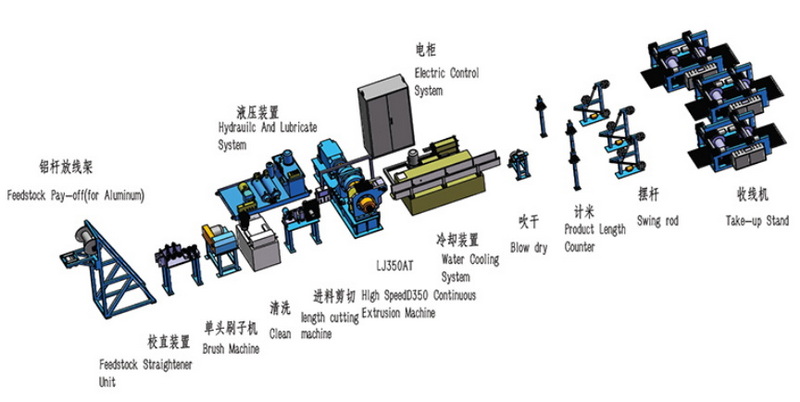

Conair Group, established in 1956, is renowned for providing over 450 auxiliary equipment solutions for plastics processing. Their extrusion equipment is designed to improve efficiency and productivity in industries such as automotive, packaging, medical devices, and more. Conair's extrusion solutions include line-control systems, film and sheet scrap-reclaim systems, and downstream equipment for pipe and profile extrusion.

Conair Extrusion Development & Testing Lab

Conair operates an advanced extrusion lab in Pinconning, Michigan, dedicated to developing and testing complete extrusion systems. This 8,000-square-foot facility houses five production-scale extruders and is staffed by experienced process engineers. It is equipped to evaluate and maximize the performance of entire extrusion lines, including downstream equipment and auxiliary systems like dryers and blenders[2][4].

The lab conducts factory acceptance testing (FAT) to confirm that new extrusion lines meet performance guarantees. It also conducts trials for extrusion companies, helping them perfect line setups for new products or experiment with new equipment and processing techniques to maximize productivity[2].

Industries Utilizing Conair Extrusion Equipment

1. Automotive Industry

The automotive sector benefits significantly from Conair extrusion equipment, particularly in the production of components such as fuel lines and dashboard trim. Conair's solutions help ensure consistent quality and efficiency in these processes. The lab at Pinconning has seen an uptick in automotive projects, including multilayer fuel lines[4].

2. Packaging Industry

In packaging, Conair equipment is used for producing plastic containers, bottles, and caps. The focus is on precision and speed to meet high demand while maintaining product integrity. Conair's extrusion auxiliary equipment, such as pullers, cutters, and coilers, play a crucial role in ensuring smooth production[6].

3. Medical Devices Industry

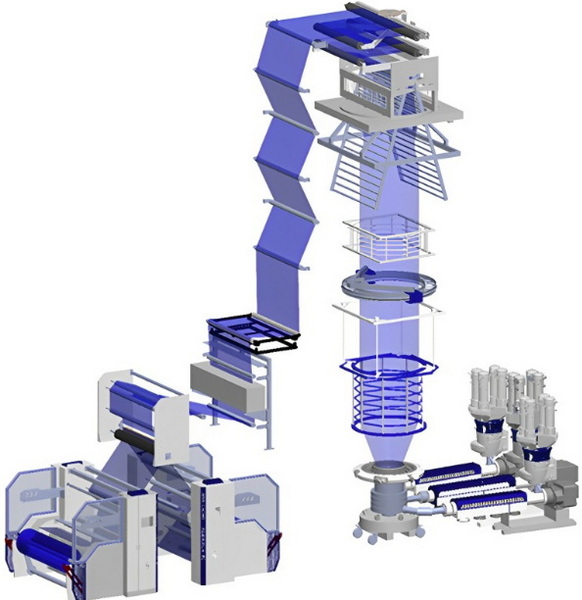

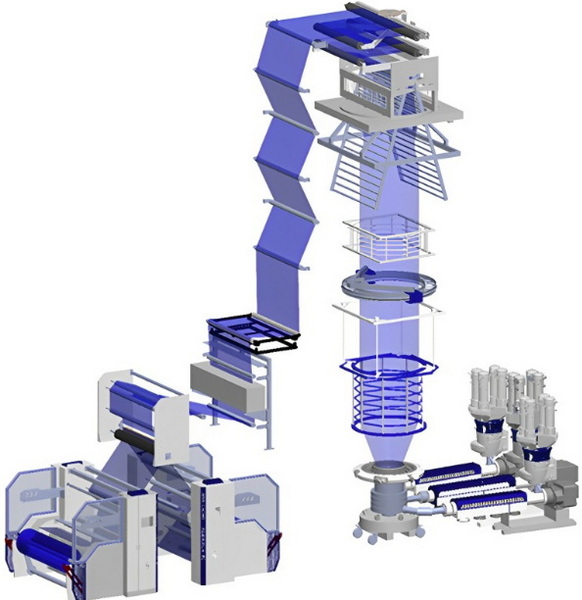

Conair plays a crucial role in the medical sector by providing equipment for precision medical tubing, such as cardiac and brain catheters. Their MedLine M-TPC-1 planetary cutter is designed for particle-free cutting, enhancing product quality and safety. The cutter allows for continuous and precise cutting of extruded tubing into short pipettes, eliminating the need for separate cutting processes[3].

4. Building and Construction Industry

In construction, Conair equipment is used for extruding siding, pipes, and profiles. These products require durability and consistency, which Conair's solutions help achieve. The lab at Pinconning also supports trials for larger equipment used in construction, such as siding and pipe extrusion[4].

Benefits of Using Conair Extrusion Equipment

- Efficiency and Productivity: Conair equipment is designed to optimize production processes, reducing waste and increasing output. For instance, their ProfileMaster line offers calibration and cooling tables, haul-offs, and cutting units that enhance precision and productivity in profile extrusion[1].

- Quality Assurance: By ensuring precise control over extrusion conditions, Conair equipment helps maintain consistent product quality. This is particularly important in medical applications where precision is critical[3].

- Innovation: Conair's research and development efforts continuously improve their equipment, offering cutting-edge solutions for various industries. Their use of AI in systems like the Conveying with Optimizer enhances process stability and automates complex adjustments[5].

Conair's ProfileMaster Equipment Line

Conair recently launched the ProfileMaster equipment line, which includes downstream profile extrusion equipment for small to large profiles. This line features calibration and cooling tables, haul-offs, cutting units, and tilting tables. The ProfileMaster calibration tables are available in various configurations to accommodate different profile sizes and cooling requirements, ensuring flexibility and precision in production[1].

Conair's Role in Medical Manufacturing

In medical manufacturing, Conair's equipment is crucial for producing precision medical tubing. The MedLine M-TPC-1 planetary cutter is designed for particle-free cutting, which is essential for medical-grade plastics. This cutter allows for continuous and precise cutting of extruded tubing into short pipettes, integrating seamlessly into the extrusion line[3].

Conair's Extrusion Lab Capabilities

Conair's extrusion lab is equipped with advanced technology, including product-specific screws, melt pumps, and high-temperature capabilities for resins like FEP and PEEK. The lab also features discrete and microprocessor controls, along with the latest in-line gauging equipment. This setup allows for comprehensive testing and development of extrusion lines, ensuring that equipment meets performance guarantees before installation[2][4].

Conclusion

Conair extrusion equipment is a vital component in several industries, including automotive, packaging, medical devices, and construction. Its versatility, efficiency, and focus on quality make it an indispensable tool for enhancing production processes. As technology advances, Conair continues to innovate, providing solutions that meet the evolving needs of these sectors.

FAQs

1. What types of industries primarily use Conair extrusion equipment?

Conair extrusion equipment is primarily used in industries such as automotive, packaging, medical devices, and building and construction.

2. What are the key features of Conair's extrusion lab?

Conair's extrusion lab is an 8,000-square-foot facility equipped with five production-scale extruders. It is designed to evaluate and maximize the performance of entire extrusion lines, including downstream equipment and auxiliary systems like dryers and blenders.

3. How does Conair support the medical devices industry?

Conair supports the medical devices industry by providing equipment for precision medical tubing, such as cardiac and brain catheters. Their MedLine M-TPC-1 planetary cutter is designed for particle-free cutting.

4. What are the benefits of using Conair extrusion equipment?

The benefits include enhanced efficiency and productivity, quality assurance through precise control, and continuous innovation in equipment design.

5. Where is Conair's extrusion lab located?

Conair's extrusion lab is located in Pinconning, Michigan.

Citations:

[1] https://www.plasticsmachinerymanufacturing.com/extrusion/article/55064364/conair-group-conair-launches-profilemaster-equipment-line

[2] https://plasticshotline.com/news/conair-lab-drives-extrusion-innovation-and-performance-improvement/

[3] https://www.plasticsmachinerymanufacturing.com/extrusion/article/53042890/conair-group-conair-demonstrates-new-equipment-for-medical-manufacturing

[4] https://www.plasticsmachinerymanufacturing.com/blow-molding/article/13000212/conair-enhances-extrusion-lab-at-mich-factory

[5] https://www.plasticsmachinerymanufacturing.com/manufacturing/article/55135054/conair-emphasizes-service-advanced-technology

[6] https://www.conairgroup.com/products/extrusion/

[7] https://www.arlingtonmachinery.com/brands/pl.b.1072.0/conair/

[8] https://www.plasticsnews.com/news/conair-boosts-controls-auxiliary-equipment

[9] https://www.conairgroup.com/about/

[10] https://www.conairgroup.com/resources/resource/extrusion-processing-basic-guide-to-auxiliary-equipment/

[11] https://www.conairgroup.com/products/cleanroom-ready/downstream-extrusion/

[12] https://www.plasticstoday.com/plastics-processing/conair

[13] https://www.ptonline.com/suppliers/conair

[14] https://www.industrysourcing.com/article/Conair-to-unveil-multiple-products-and-technology-at-NPE-2024

[15] https://www.youtube.com/watch?v=mTgzggagIeU

[16] https://plasticsbusinessmag.com/articles/2020/technology-trends-in-auxiliary-equipment/

[17] https://www.plasticsmachinerymanufacturing.com/extrusion/company/21118792/conair-group

[18] https://www.industrysourcing.com/article/highly-flexible-medical-extrusion-line

[19] https://www.youtube.com/watch?v=QpldSHjT_q4

[20] https://www.medicaldesignandoutsourcing.com/conair-equipment-simplifies-cleanrooms/