Content Menu

● Introduction to Fully Automatic Extrusion Machines

>> Benefits of Fully Automatic Extrusion Machines

● Types of Fully Automatic Extrusion Machines

>> Single Screw vs. Double Screw Extruders

>> Pipe Extrusion Machines

>> Profile Extrusion Machines

>> Blown Film Extrusion Machines

● Best Fully Automatic Extrusion Machine Price

● Choosing the Best Fully Automatic Extrusion Machine for Your Business

>> Considerations

● Innovations in Extrusion Technology

● Applications Across Industries

>> Plastics Industry

>> Food Industry

>> Metals Industry

>> Ceramics and Composites

● Top Manufacturers of Twin Screw Extruders

● Energy Efficiency and Sustainability

● Conclusion

● FAQs

>> 1. What are the main types of fully automatic extrusion machines?

>> 2. How do I determine the best fully automatic extrusion machine price for my business?

>> 3. What are the benefits of using fully automatic extrusion machines?

>> 4. How do I choose between single screw and double screw extruders?

>> 5. What are some key considerations when selecting an extrusion machine?

● Citations:

In today's manufacturing landscape, fully automatic extrusion machines have become indispensable for businesses seeking to enhance efficiency, reduce costs, and improve product quality. These machines are versatile, capable of processing a wide range of materials, from plastics to metals, and are used in various industries such as construction, automotive, and aerospace. This article will guide you through the selection process of the best fully automatic extrusion machine for your business, highlighting key features, applications, and considerations.

Introduction to Fully Automatic Extrusion Machines

Fully automatic extrusion machines are designed to automate the extrusion process, which involves forcing raw materials through a die to create products with specific cross-sectional profiles. These machines are equipped with advanced technologies such as real-time monitoring systems, energy-efficient designs, and flexible material processing capabilities.

Benefits of Fully Automatic Extrusion Machines

1. High-Speed Production: These machines can process large volumes of material quickly, enabling businesses to meet high demand without compromising product quality.

2. Real-Time Monitoring and Control: Operators can detect anomalies and make adjustments promptly, ensuring optimal production conditions.

3. Energy Efficiency: Modern extruders are designed to reduce the carbon footprint of manufacturing processes.

4. Material Optimization: They optimize material usage, reducing waste and making production more environmentally friendly.

Types of Fully Automatic Extrusion Machines

Single Screw vs. Double Screw Extruders

- Single Screw Extruders: These are cost-effective and suitable for modest production needs. However, they have lower production capacities compared to double screw models.

- Double Screw Extruders: These offer higher efficiency and faster production rates due to the intermeshing screws, but they are more expensive.

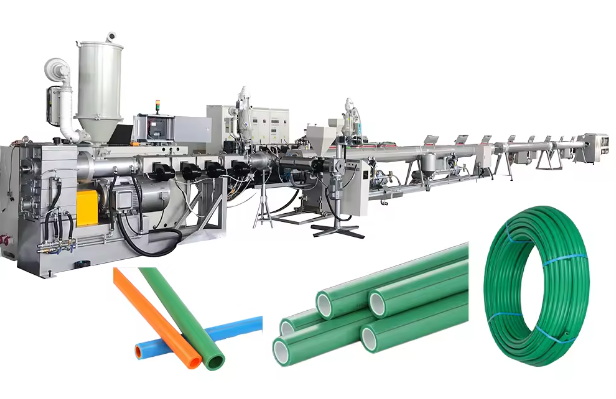

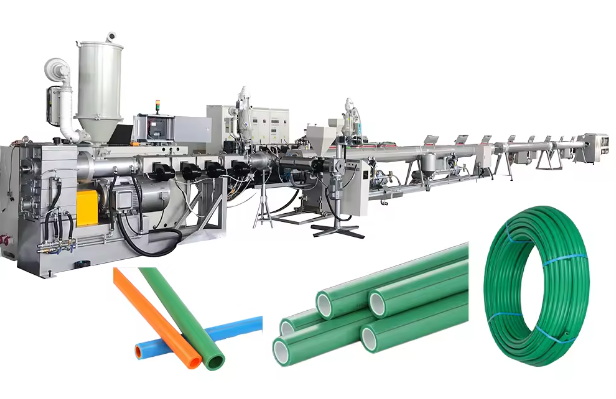

Pipe Extrusion Machines

These machines are specifically designed for producing pipes and tubes. They are crucial in industries such as plumbing and construction.

Profile Extrusion Machines

These machines are used to produce profiles such as aluminum or PVC frames. They are versatile and can handle various materials.

Blown Film Extrusion Machines

These machines are used to produce plastic films, which are essential in packaging industries.

Best Fully Automatic Extrusion Machine Price

The price of fully automatic extrusion machines varies widely based on the type, capacity, and features. Here are some approximate price ranges:

- Pipe Extrusion Machines: $30,000 to $150,000

- Profile Extrusion Machines: $25,000 to $100,000

- Blown Film Extrusion Machines: Prices vary significantly based on the complexity and output capacity, but generally fall between $19,000 and $96,000 for basic models.

When considering the best fully automatic extrusion machine price, it's essential to balance cost with the machine's capabilities and your business needs.

Choosing the Best Fully Automatic Extrusion Machine for Your Business

Considerations

1. Production Needs: Determine the output capacity required and the type of products you will be producing.

2. Material Type: Ensure the machine can handle the specific materials you plan to use.

3. Budget: Consider both the initial investment and ongoing operational costs.

4. Automation and Control Systems: Opt for machines with advanced PLC control and user-friendly interfaces for precision and ease of operation.

Innovations in Extrusion Technology

Recent advancements in extrusion technology include the integration of artificial intelligence (AI) and the Internet of Things (IoT) to enhance precision and efficiency. AI algorithms analyze real-time data from the extrusion machinery, allowing for immediate adjustments and ensuring that each profile meets exact specifications. This not only enhances product quality but also contributes to resource efficiency[1].

Hybrid extrusion techniques, combining traditional methods with advanced processes, have emerged to address the demand for profiles with enhanced strength and formability. These methods optimize the material's properties, opening up new possibilities for applications in aerospace, automotive, and other industries where both strength and malleability are critical[1].

Sustainability is at the forefront of recent innovations. From energy-efficient extrusion processes to the use of recycled materials, the industry is embracing environmentally conscious practices. These advancements not only reduce the carbon footprint of production but also align with global efforts to create more sustainable manufacturing solutions[1].

The integration of 3D printing technology with extrusion has opened up new frontiers in customization. This combination allows for the creation of intricate and tailored designs, offering architects, engineers, and designers unparalleled freedom in realizing their visions[1].

High-pressure extrusion allows for the production of complex, high-strength profiles necessary for critical industries like aerospace and defense. This process results in stronger, more durable profiles that meet exact specifications[7].

Applications Across Industries

Plastics Industry

Extruders are extensively used to produce a variety of plastic products, including pipes, sheets, films, and profiles. The process allows for precise control over the shape and properties of the final product[2].

Food Industry

Food extruders are used to produce snacks, cereals, pasta, and pet foods. The extrusion process can modify the texture, shape, and nutritional content of food products, making it a valuable tool for food manufacturers[2].

Metals Industry

Metal extrusion is used to create complex shapes and profiles from metals such as aluminum, copper, and steel. This process is commonly used in the automotive, aerospace, and construction industries[2].

Ceramics and Composites

Extrusion technology is also applied in the production of ceramic and composite materials, offering unique properties for specialized applications.

Top Manufacturers of Twin Screw Extruders

Some of the leading manufacturers of twin-screw extruders include UDTECH, Coperion, Leistritz, Milacron, and KraussMaffei. These companies offer innovative solutions with advanced technology and customer support[3].

Energy Efficiency and Sustainability

Modern extrusion machines are designed to be energy-efficient, reducing the carbon footprint of the manufacturing process. This is particularly important for industries aiming to minimize their environmental impact[5]. The use of recycled materials and closed-loop recycling systems further enhances sustainability by reducing waste and emissions[1].

Conclusion

Fully automatic extrusion machines are crucial for businesses aiming to enhance production efficiency and product quality. By understanding the different types of machines available and considering factors such as production needs, material types, and budget, you can select the best machine for your business. The best fully automatic extrusion machine price will depend on balancing these factors with the machine's capabilities.

FAQs

1. What are the main types of fully automatic extrusion machines?

Fully automatic extrusion machines include pipe extrusion machines, profile extrusion machines, blown film extrusion machines, and co-extrusion machines. Each type is designed for specific applications and materials.

2. How do I determine the best fully automatic extrusion machine price for my business?

To determine the best price, consider your production needs, the type of materials you will be processing, and the machine's features. Balancing these factors with the cost will help you find the most suitable option.

3. What are the benefits of using fully automatic extrusion machines?

Benefits include high-speed production, reduced material waste, consistent product quality, and energy efficiency. These machines also offer flexibility in material processing and labor efficiency.

4. How do I choose between single screw and double screw extruders?

Single screw extruders are cost-effective and suitable for modest production needs, while double screw extruders offer higher efficiency and faster production rates but are more expensive. Choose based on your production volume and budget.

5. What are some key considerations when selecting an extrusion machine?

Key considerations include production capacity, material compatibility, budget, automation level, and after-sales support. Ensure the machine complies with safety standards and is easy to maintain.

Citations:

[1] https://www.yjing-extrusion.com/what-are-the-latest-innovations-in-aluminum-extruder-technology-for-2024.html

[2] https://engitech.in/extrusion-machines-and-extruders-guide/

[3] https://ud-machine.com/blog/top-twin-screw-extruder-manufacturers/

[4] https://www.machinedesign.com/3d-printing-cad/article/55248644/redetec-high-risk-high-reward-investing-in-game-changing-plastics-extrusion-technology

[5] https://www.yjing-extrusion.com/how-does-an-automatic-extrusion-machine-improve-production-efficiency.html

[6] https://www.prm-taiwan.com/blog/leading-way-in-customized-extrusion-solutions-sinoalloys-highlight-at-k-show_527

[7] https://nationalindustries.world/2025/01/02/the-future-of-aluminum-how-extrusion-technology-is-transforming-industries/

[8] https://ensun.io/search/extrusion-machine

[9] https://www.globenewswire.com/news-release/2025/02/05/3021359/0/en/Plastic-Extrusion-Machine-Market-to-Grow-at-4-7-CAGR-During-2025-2035-Boosting-Global-Industry-to-USD-12-343-2-Million-by-2035-Future-Market-Insights-Inc.html

[10] https://www.jwellmachine.com/analysis-of-plastic-extrusion-technology/

[11] https://www.thebusinessresearchcompany.com/report/extrusion-machinery-global-market-report

[12] https://www.promarketreports.com/reports/extruding-machines-33875

[13] https://www.mywaymachine.com/high-capacity-extrusion-blow-molding-for-industrial-applications/

[14] https://www.globenewswire.com/news-release/2025/01/01/3003246/0/en/Europe-Plastic-Extrusion-Machine-Market-Valuation-is-Skyrocketing-to-Reach-US-3-901-68-Million-by-2033-Astute-Analytica.html

[15] https://www.globenewswire.com/news-release/2025/01/02/3003332/0/en/U-S-Plastic-Extrusion-Machine-Market-to-Hit-Valuation-of-US-1-548-99-Million-By-2033-Rapid-Innovation-and-Growing-Collaboration-Fueling-Market-Growth-Says-Astute-Analytica.html

[16] https://www.moldingmachinetepai.com/resources/plastic-extrusion-machines-introduction-types-application.html

[17] https://www.cognitivemarketresearch.com/extruding-machines-market-report

[18] https://www.yjing-extrusion.com/what-is-the-current-size-of-the-extrusion-equipment-market.html

[19] https://www.zjchaoxin.com/abc-3-layer-blown-film-machine/36

[20] https://www.moldingmachinetepai.com/news/what-are-the-applications-of-extrusion-blow-molding.html