Content Menu

● Understanding Aluminum Extrusions

● The 2020 Aluminum Extrusion

● The 8020 Aluminum Extrusion

● Key Differences Between 2020 and 8020 Aluminum Extrusions

>> Size and Weight

>> Strength and Load-Bearing Capacity

>> Cost

>> Availability and Accessories

>> Applications

● Choosing the Right Aluminum Extrusion

>> Assess Your Project Requirements

>> Consider Your Budget

>> Explore Available Accessories

>> Plan for Future Modifications

>> Seek Expert Advice

● Real-World Applications of 2020 and 8020 Aluminum Extrusions

>> 2020 Aluminum Extrusion in Robotics

>> 8020 Aluminum Extrusion in Industrial Automation

● Conclusion

● Frequently Asked Questions

>> 1. What is the main difference between 2020 and 8020 aluminum extrusions?

>> 2. Which aluminum extrusion is more cost-effective?

>> 3. Can I use 2020 and 8020 extrusions interchangeably?

>> 4. What types of projects are best suited for 2020 aluminum extrusions?

>> 5. What industries commonly use 8020 aluminum extrusions?

Aluminum extrusions are a popular choice in various industries due to their lightweight, strength, and versatility. Among the many options available, the 2020 and 8020 aluminum extrusions stand out as two of the most commonly used profiles. This article will explore the differences between these two types of aluminum extrusions, their applications, advantages, and how to choose the right one for your project.

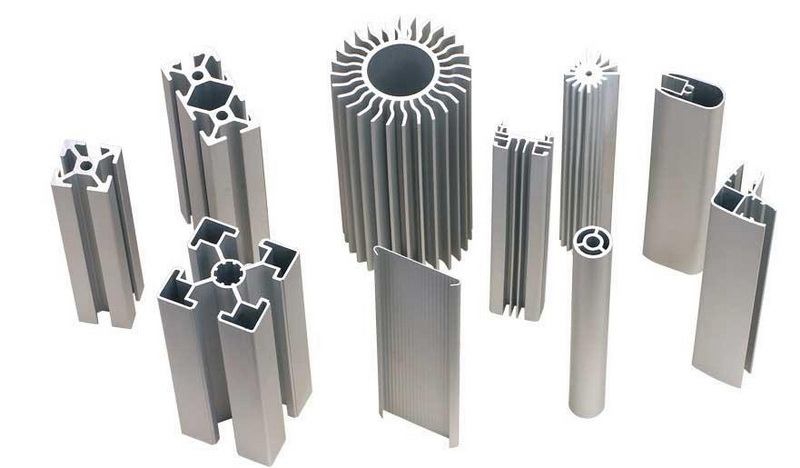

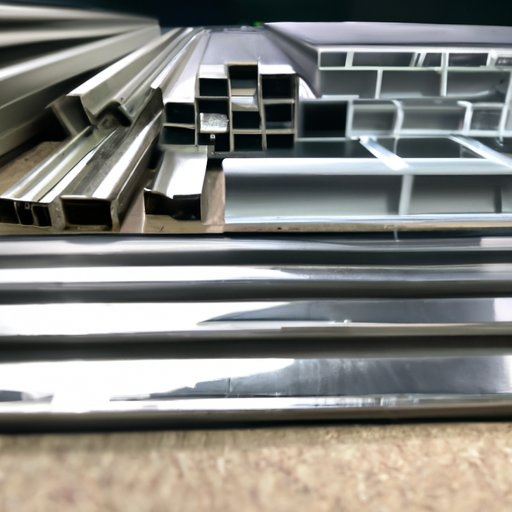

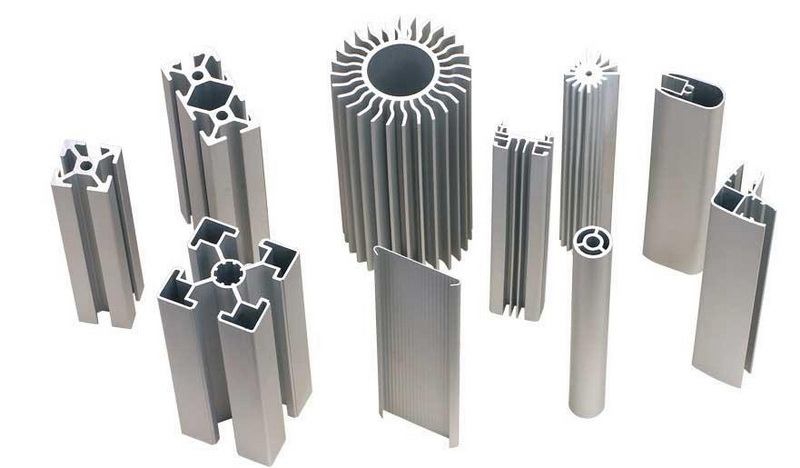

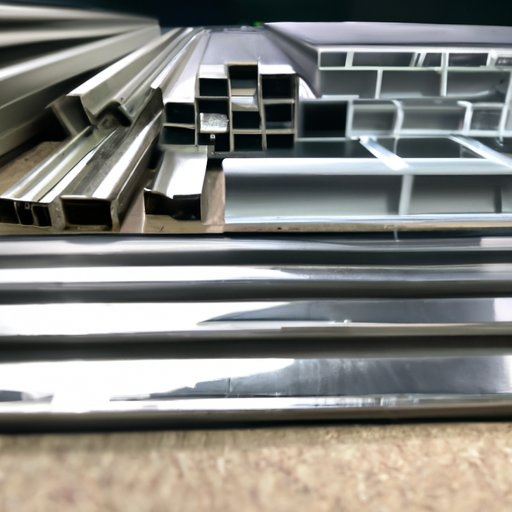

Understanding Aluminum Extrusions

Aluminum extrusion is a process that involves shaping aluminum alloy into a desired cross-sectional profile. This is achieved by forcing the aluminum through a die, which gives it the desired shape. The resulting extrusions can be used in a wide range of applications, from structural components to decorative elements.

The 2020 Aluminum Extrusion

The 2020 aluminum extrusion is part of the metric series and has a cross-section measuring 20mm x 20mm. It is commonly used in smaller-scale projects and applications that require lightweight and compact structural elements. The 2020 profile is particularly popular in the DIY community, robotics, and small machinery due to its ease of use and availability.

The 2020 extrusion is often chosen for its versatility. It can be easily cut, drilled, and assembled, making it ideal for custom projects. Additionally, the lightweight nature of the 2020 profile allows for easy handling and transportation, which is a significant advantage for hobbyists and small-scale manufacturers.

The 8020 Aluminum Extrusion

On the other hand, the 8020 aluminum extrusion has a larger cross-section of 80mm x 20mm. This profile is favored in industrial settings for constructing robust machinery frames, conveyor systems, and other heavy-duty applications. The 8020 series is known for its strength and versatility, making it suitable for a wide range of applications, including automation, robotics, and structural frameworks.

The 8020 extrusion is designed to handle heavier loads and is often used in environments where durability and strength are paramount. Its larger size allows for more complex designs and configurations, making it a preferred choice for engineers and designers working on intricate projects.

Key Differences Between 2020 and 8020 Aluminum Extrusions

When deciding between 2020 and 8020 aluminum extrusions, several factors should be considered:

Size and Weight

The most obvious difference is the size. The 2020 extrusion is smaller and lighter, making it ideal for projects where weight is a concern. This makes it suitable for applications like lightweight frames, small enclosures, and portable structures. In contrast, the 8020 extrusion is larger and heavier, providing greater strength and stability for more demanding applications.

Strength and Load-Bearing Capacity

The 8020 aluminum extrusion has a higher load-bearing capacity compared to the 2020 profile. This makes it the preferred choice for heavy-duty applications, such as industrial machinery and structural supports. If your project requires significant strength and durability, the 8020 extrusion is likely the better option.

Cost

Generally, the 2020 aluminum extrusion is less expensive than the 8020 profile. This cost difference can be significant, especially for large projects or when budget constraints are a concern. If your project does not require the additional strength of the 8020 extrusion, opting for the 2020 profile can help save costs.

Availability and Accessories

Both 2020 and 8020 aluminum extrusions have a wide range of accessories available, including brackets, connectors, and fasteners. However, the 8020 series tends to have a more extensive selection of industrial-grade accessories, making it easier to find components for complex assemblies. The 2020 series, while still well-supported, may have fewer options for heavy-duty applications.

Applications

The applications for each extrusion type vary significantly. The 2020 aluminum extrusion is commonly used in:

- DIY Projects: Ideal for hobbyists and small-scale projects.

- Robotics: Lightweight frames for robotic arms and structures.

- Furniture: Custom furniture designs that require a sleek, modern look.

In contrast, the 8020 aluminum extrusion is often used in:

- Industrial Machinery: Frames for conveyor systems and heavy equipment.

- Automation: Structural components for automated systems and robotics.

- Workstations: Sturdy workbenches and assembly stations in manufacturing environments.

Choosing the Right Aluminum Extrusion

When selecting between 2020 and 8020 aluminum extrusions, consider the following steps:

Assess Your Project Requirements

Determine the specific needs of your project, including weight constraints, load requirements, and the overall design. If your project is lightweight and does not require heavy-duty support, the 2020 extrusion may be sufficient. For projects that demand strength and stability, the 8020 extrusion is the better choice.

Consider Your Budget

Evaluate your budget and how much you are willing to spend on materials. If cost is a significant factor, the 2020 aluminum extrusion may be the more economical option. However, if your project requires the additional strength of the 8020 profile, it may be worth the investment.

Explore Available Accessories

Look into the accessories and components available for each extrusion type. If your project requires specific connectors or brackets, ensure that they are readily available for the extrusion you choose.

Plan for Future Modifications

Consider whether your project may require future modifications or expansions. The modular nature of aluminum extrusions allows for easy adjustments, but the availability of compatible components can vary between the two profiles.

Seek Expert Advice

If you are unsure which extrusion to choose, consult with experts or suppliers who can provide guidance based on your project's specific needs. They can help you understand the advantages and limitations of each profile.

Real-World Applications of 2020 and 8020 Aluminum Extrusions

To further illustrate the differences between 2020 and 8020 aluminum extrusions, let's look at some real-world applications.

2020 Aluminum Extrusion in Robotics

In the field of robotics, the 2020 aluminum extrusion is often used to create lightweight frames for robotic arms and mobile platforms. Its ease of assembly allows engineers to quickly prototype and iterate designs, making it a favorite among hobbyists and professionals alike. The ability to customize the frame with various accessories, such as brackets and connectors, enhances its versatility.

8020 Aluminum Extrusion in Industrial Automation

Conversely, the 8020 aluminum extrusion is commonly found in industrial automation systems. Its robust design makes it suitable for constructing conveyor systems, assembly lines, and heavy machinery frames. The strength of the 8020 profile ensures that it can withstand the rigors of industrial environments, providing reliable support for complex systems.

Conclusion

In conclusion, both 2020 and 8020 aluminum extrusions offer unique advantages and are suitable for different applications. The choice between the two ultimately depends on your project requirements, budget, and intended use. By understanding the key differences and considering your specific needs, you can make an informed decision that will lead to a successful project.

Frequently Asked Questions

1. What is the main difference between 2020 and 8020 aluminum extrusions?

The main difference is their size and load-bearing capacity. The 2020 extrusion is smaller and lighter, while the 8020 extrusion is larger and stronger, making it suitable for heavy-duty applications.

2. Which aluminum extrusion is more cost-effective?

Generally, the 2020 aluminum extrusion is less expensive than the 8020 profile, making it a more cost-effective option for lightweight projects.

3. Can I use 2020 and 8020 extrusions interchangeably?

While both can be used in similar applications, they are not interchangeable due to their different sizes and load capacities. It is essential to choose the right extrusion based on your project requirements.

4. What types of projects are best suited for 2020 aluminum extrusions?

The 2020 aluminum extrusion is ideal for DIY projects, robotics, and lightweight furniture designs.

5. What industries commonly use 8020 aluminum extrusions?

The 8020 aluminum extrusion is commonly used in industrial machinery, automation, and manufacturing environments due to its strength and versatility.