Content Menu

● Introduction to the Folger Tech FT-5

>> Key Features of the FT-5

● Why Upgrade to an Aluminum Extruder?

>> Popular Aluminum Extruder Upgrades

● Folger Tech FT-5 Aluminum Extruder Upgrade Process

>> Step 1: Prepare the New Extruder

>> Step 2: Remove the Stock Extruder

>> Step 3: Install the New Extruder

>> Step 4: Calibrate the Extruder

● Conclusion

● Frequently Asked Questions

>> 1. What are the benefits of using an aluminum extruder over a plastic one?

>> 2. How do I choose the right aluminum extruder for my Folger Tech FT-5?

>> 3. Can I use a 2.85mm filament with the Titan Extruder on the FT-5?

>> 4. How do I calibrate the extruder steps per mm (esteps) after installing a new extruder?

>> 5. Are there any specific tools required for installing an aluminum extruder on the FT-5?

● Citations:

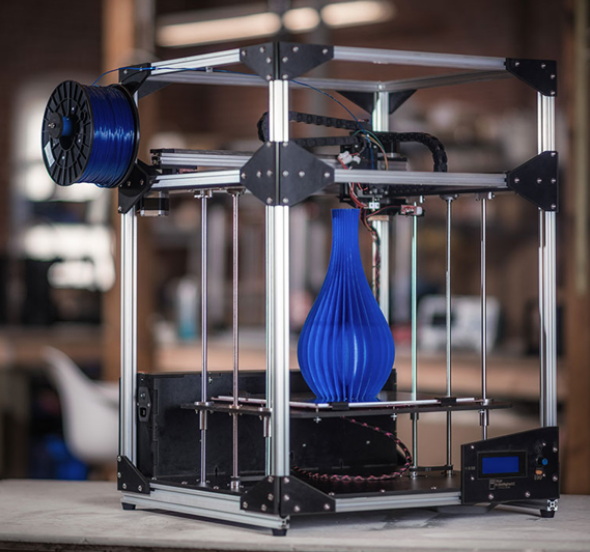

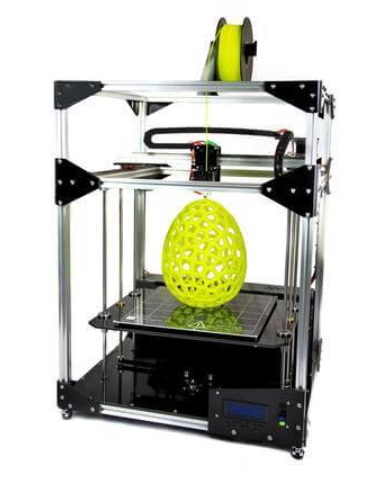

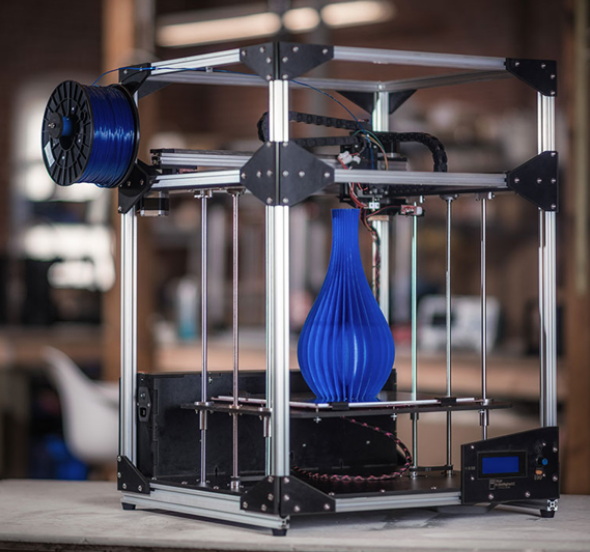

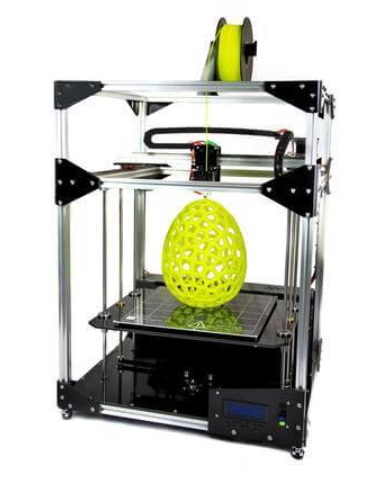

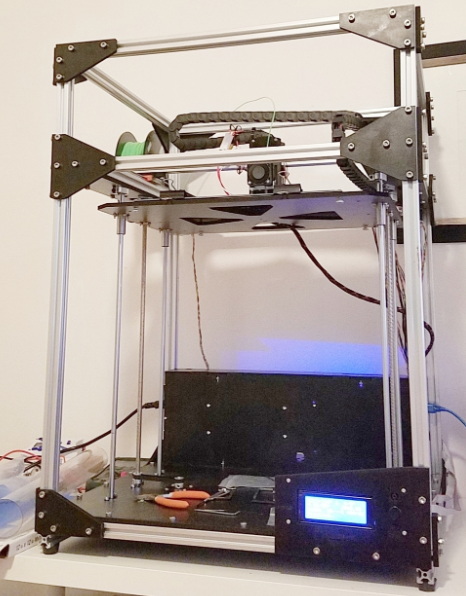

The Folger Tech FT-5 is a versatile and highly customizable 3D printer kit, known for its large build volume and robust construction. One of the key areas where users often look to upgrade is the extruder system, as it can significantly improve print quality and reliability. In this article, we will explore the best aluminum extruder options for the Folger Tech FT-5, focusing on upgrades that enhance performance, durability, and ease of use.

Introduction to the Folger Tech FT-5

The Folger Tech FT-5 is a popular DIY 3D printer kit that offers a build area of 300x300x400mm. It features linear rails for smooth X and Y movements, dual Y and Z motors for increased speed and stability, and an aluminum build surface capable of handling a variety of filaments, including PLA and ABS[5][6].

Key Features of the FT-5

- Large Build Volume: 300x300x400mm, ideal for printing large models.

- Linear Rails: Provide smooth and precise movement.

- Dual Y and Z Motors: Enhance stability and speed.

- Aluminum Build Surface: Suitable for printing with PLA and ABS.

Why Upgrade to an Aluminum Extruder?

Upgrading to an aluminum extruder can offer several benefits over the stock extruder:

- Durability: Aluminum extruders are more robust and less prone to wear compared to plastic or melamine components.

- Heat Dissipation: Aluminum is a better conductor of heat, which can help in maintaining consistent temperatures during printing.

- Precision: Aluminum extruders often provide better filament grip and control, leading to improved print quality.

Popular Aluminum Extruder Upgrades

1. Titan Extruder: Known for its robust design and ability to handle a wide range of filaments, including 2.85mm and 1.75mm diameters. It is a popular choice for upgrading the FT-5 due to its reliability and ease of installation[1].

2. E3D V6 Hotend with Aluminum Mount: Combining the E3D V6 hotend with an aluminum extruder mount provides excellent thermal performance and filament control. The E3D V6 is highly regarded for its precision and versatility[1].

3. Bondtech BMG Extruder: Offers a dual-drive system for improved filament grip and control. It is compatible with a variety of hotends and is known for its reliability in handling flexible filaments.

Folger Tech FT-5 Aluminum Extruder Upgrade Process

Upgrading the extruder on the FT-5 involves several steps:

Step 1: Prepare the New Extruder

- Ensure all necessary parts are included with your new extruder, such as screws, nuts, and any specific mounting hardware.

- If using a Titan or Bondtech extruder, verify compatibility with your existing hotend.

Step 2: Remove the Stock Extruder

- Disconnect the filament and any electrical connections from the stock extruder.

- Remove the screws holding the stock extruder in place and gently pull it away from the printer frame.

Step 3: Install the New Extruder

- Mount the new extruder using the provided hardware. Ensure it is securely fastened to the printer frame.

- Reconnect any electrical connections and load filament into the new extruder.

Step 4: Calibrate the Extruder

- Perform an extruder calibration to ensure accurate filament flow. This may involve adjusting the extruder steps per mm (esteps) in your printer's firmware.

Conclusion

Upgrading the extruder on the Folger Tech FT-5 can significantly enhance print quality and reliability. Aluminum extruders like the Titan and Bondtech models offer improved durability and filament control, making them excellent choices for users looking to maximize their printer's potential. Whether you're printing with PLA, ABS, or more exotic materials, an aluminum extruder upgrade can help ensure consistent results.

Frequently Asked Questions

1. What are the benefits of using an aluminum extruder over a plastic one?

Aluminum extruders are more durable, provide better heat dissipation, and offer improved filament control compared to plastic extruders.

2. How do I choose the right aluminum extruder for my Folger Tech FT-5?

Consider factors like compatibility with your existing hotend, the type of filament you use most often, and whether you need features like dual-drive for flexible filaments.

3. Can I use a 2.85mm filament with the Titan Extruder on the FT-5?

Yes, the Titan Extruder supports both 1.75mm and 2.85mm filaments, making it versatile for different printing needs.

4. How do I calibrate the extruder steps per mm (esteps) after installing a new extruder?

Calibration involves measuring the actual filament extruded against the requested amount and adjusting the esteps value in your printer's firmware accordingly.

5. Are there any specific tools required for installing an aluminum extruder on the FT-5?

Typically, you will need basic tools like Allen wrenches, screwdrivers, and possibly a drill for any custom modifications.

Citations:

[1] http://3dprintingforum.us/viewtopic.php?t=570

[2] https://www.treatstock.com/static/uploads/printers/FT-5-Manual-Draft-V8-.pdf

[3] https://github.com/celer/FT5_CoreXY_EVA

[4] https://forum.duet3d.com/topic/18809/trying-to-get-a-folgertech-ft5-r2-kit-dialed-in

[5] https://www.treatstock.com/machines/item/305-folgertech-ft5

[6] https://www.3dbeginners.com/folger-tech-ft-5-review/

[7] https://713maker.com/en/ft-5

[8] https://www.reddit.com/r/3Dprinting/comments/5ara8r/my_adventure_with_the_folgertech_ft5_now_called/

[9] https://www.reddit.com/r/folgertech/comments/1avjxaa/ft5_corexy_upgrade_found_a_new_design/

[10] https://3dprinteruniverse.com/products/folger-tech-ft-5-large-scale-3d-printer-kit

[11] https://www.reddit.com/r/3Dprinting/comments/17dv5fu/folgertech_ft5_question/

[12] https://www.youtube.com/watch?v=dwL71pTHkEk

[13] https://www.3dprintersbay.com/folger-tech-ft-5-large-scale-3d-printer-kit

[14] https://www.youtube.com/watch?v=r70NqZjuZq4

[15] http://www.soliforum.com/topic/17300/folger-ft5-r2-printer-head/

[16] https://www.youtube.com/watch?v=NVnJV1RAM-0

[17] https://www.youtube.com/watch?v=m41ksuBNwpI

[18] https://www.youtube.com/watch?v=7Ys4MalVHMI

[19] https://www.youtube.com/watch?v=MKbc2PEuxlw

[20] http://www.soliforum.com/topic/16800/folgertech-ft5-r2-build/page/2/

[21] https://www.yeggi.com/q/folger+tech+ft+5/

[22] https://www.youtube.com/watch?v=00Q1NRQrEhU

[23] https://www.printables.com/tag/folgertechft5

[24] https://www.youtube.com/watch?v=xu-Ej391Ycg

[25] https://www.thingiverse.com/thing:3699183

[26] https://www.youtube.com/playlist?list=PLs5rsD0wRejTJ_3vB5Im_nkjhD2Nb8D4z

[27] https://www.youtube.com/watch?v=yyNmC8bGH-s

[28] https://www.youtube.com/watch?v=qtDKhpYtsqI

[29] https://www.youtube.com/watch?v=chpUiMCm48M

[30] https://www.manualslib.com/manual/1371283/Folger-Tech-Ft-5.html

[31] https://www.youtube.com/watch?v=Q85tSHDfi6U

[32] https://www.youtube.com/watch?v=b0RbRVUiTps

[33] https://www.aniwaa.com/product/3d-printers/folger-tech-ft-5-r2/

[34] https://www.3dprintingforum.org/forum/general/share-a-project/106154-folgertech-ft-5-build-thread