Content Menu

● Understanding 80/20 Aluminum Extrusions

>> Benefits of Using 80/20 Aluminum Extrusions

● Essential Accessories for Building Custom Frames

>> Connectors

>> Fasteners

>> End Caps

>> Brackets and Mounts

>> Panels and Covers

>> Wheels and Casters

>> Linear Motion Components

>> Custom Machining Services

● Tips for Building Custom Frames

● Common Applications of 80/20 Aluminum Extrusions

● Conclusion

● Frequently Asked Questions

>> 1. What are the advantages of using aluminum extrusions over other materials?

>> 2. Can I modify my aluminum frame after it is built?

>> 3. What tools do I need to assemble an aluminum frame?

>> 4. How do I ensure my frame is stable?

>> 5. Where can I find custom machining services for aluminum extrusions?

Building custom frames using 80/20 aluminum extrusions has become increasingly popular among DIY enthusiasts, engineers, and manufacturers alike. The versatility and modularity of these extrusions allow for the creation of a wide range of structures, from simple frames to complex machinery. However, to maximize the potential of 80/20 aluminum extrusions, it is essential to understand which accessories are necessary for building robust and functional custom frames. In this article, we will explore the essential accessories, their uses, and how they contribute to the overall effectiveness of your projects.

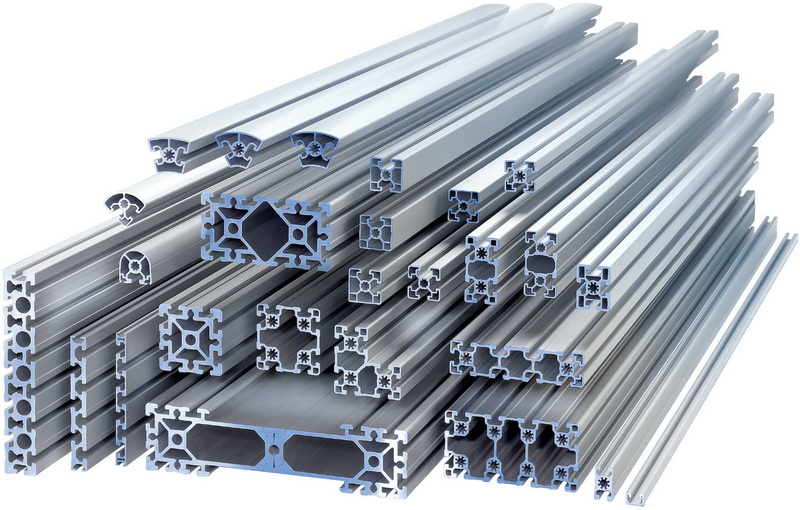

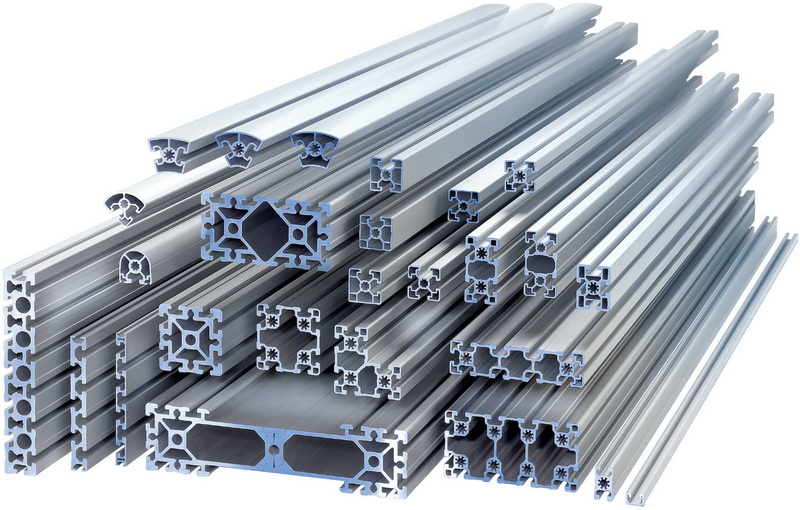

Understanding 80/20 Aluminum Extrusions

80/20 aluminum extrusions are T-slot profiles made from high-quality aluminum. The T-slot design allows for easy assembly and disassembly, making it ideal for projects that may require modifications or adjustments over time. These extrusions come in various sizes and shapes, providing flexibility in design and application.

Benefits of Using 80/20 Aluminum Extrusions

1. Modularity: The T-slot design allows for easy integration of various components, making it simple to customize and expand your frame as needed.

2. Lightweight yet Strong: Aluminum is known for its strength-to-weight ratio, making it an excellent choice for structural applications without adding unnecessary weight.

3. Corrosion Resistance: Aluminum is naturally resistant to corrosion, ensuring longevity and durability in various environments.

4. Ease of Assembly: The T-slot design allows for quick and easy assembly using standard tools, reducing the time and effort required to build custom frames.

Essential Accessories for Building Custom Frames

To effectively utilize 80/20 aluminum extrusions, several accessories are essential. These accessories enhance the functionality, stability, and versatility of your custom frames.

Connectors

Connectors are crucial for joining different sections of aluminum extrusions. They come in various types, including:

- Corner Brackets: Used to create right angles in frames, corner brackets provide stability and support.

- T-Slot Connectors: These connectors fit into the T-slots of the extrusions, allowing for secure connections without the need for drilling.

- Splice Plates: Used to join two lengths of extrusion together, splice plates ensure a strong and stable connection.

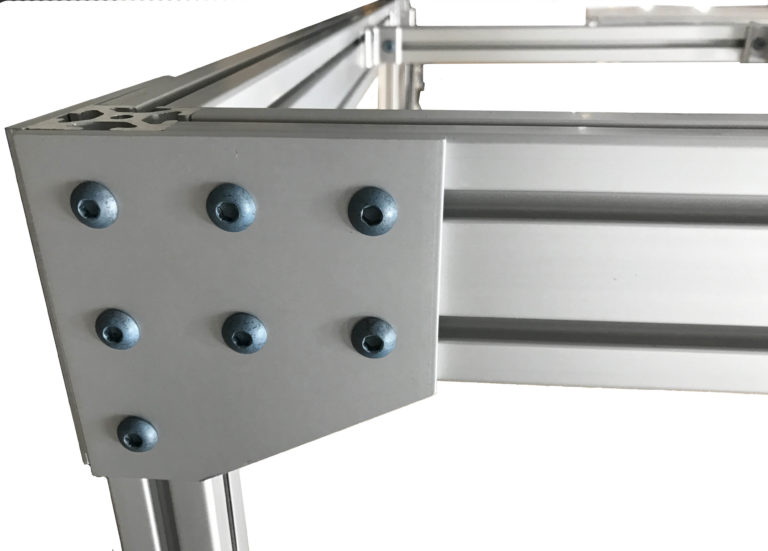

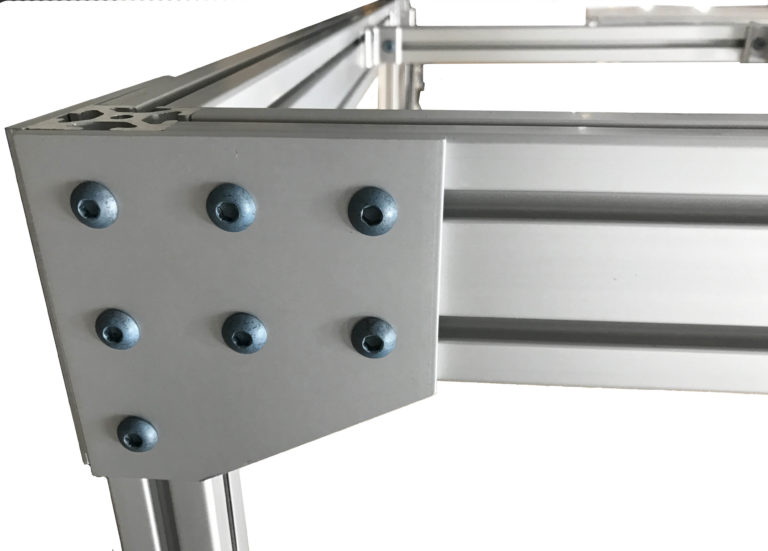

Fasteners

Fasteners are essential for securing connectors and other components to the aluminum extrusions. Common types of fasteners include:

- Bolts and Nuts: Standard bolts and nuts are used to secure connections, providing a strong hold.

- T-Nuts: These nuts slide into the T-slots of the extrusions, allowing for easy attachment of components without external hardware.

- Washers: Used to distribute the load of the fastener, washers help prevent damage to the extrusion and ensure a secure fit.

End Caps

End caps are used to cover the open ends of aluminum extrusions. They serve several purposes:

- Safety: End caps prevent sharp edges from being exposed, reducing the risk of injury.

- Aesthetics: They provide a finished look to the frame, enhancing its overall appearance.

- Dust Protection: End caps help keep dust and debris out of the extrusions, maintaining cleanliness and functionality.

Brackets and Mounts

Brackets and mounts are used to attach additional components to the frame, such as shelves, panels, or machinery. They come in various styles, including:

- L-Brackets: Used for mounting shelves or other flat surfaces to the frame.

- U-Brackets: Ideal for securing cylindrical objects or providing additional support.

- Adjustable Mounts: These allow for height and angle adjustments, providing flexibility in design.

Panels and Covers

Panels and covers can be added to aluminum frames for various purposes, including:

- Enclosures: Creating a protective enclosure for machinery or sensitive equipment.

- Shelving: Adding shelves for storage or display purposes.

- Safety Guards: Installing panels to protect operators from moving parts or hazards.

Wheels and Casters

For mobile applications, adding wheels or casters to your aluminum frame can enhance its functionality. These accessories allow for easy movement of the frame, making it ideal for workstations or equipment that needs to be relocated frequently.

Linear Motion Components

If your project involves moving parts, consider incorporating linear motion components such as:

- Linear Rails: These provide a smooth path for moving parts, ideal for applications like sliding doors or automated machinery.

- Carriages: Used in conjunction with linear rails, carriages allow for smooth movement along the rail.

Custom Machining Services

For specialized projects, custom machining services can provide tailored solutions. This may include cutting, drilling, or fabricating specific components to meet unique design requirements.

Tips for Building Custom Frames

1. Plan Your Design: Before starting, sketch out your design and determine the necessary components. This will help you visualize the final product and ensure you have all the required accessories.

2. Measure Twice, Cut Once: Accurate measurements are crucial for a successful build. Double-check your dimensions before cutting any extrusions.

3. Use the Right Tools: Standard tools such as wrenches, screwdrivers, and saws are typically sufficient for assembly. However, specialized tools like a miter saw can provide cleaner cuts for angled joints.

4. Test Stability: Once assembled, test the stability of your frame before adding any additional components or weight. This will help identify any weak points that may need reinforcement.

Common Applications of 80/20 Aluminum Extrusions

80/20 aluminum extrusions are used in a variety of applications across different industries. Some common uses include:

- Workstations: Custom workstations can be built to fit specific tasks, providing ergonomic solutions for various jobs.

- Machine Guards: Aluminum frames can be used to create safety enclosures around machinery, protecting operators from moving parts.

- Display Racks: Retail environments often utilize aluminum extrusions for creating attractive and functional display racks.

- Robotics: Many robotics projects use aluminum extrusions for building frames that house components and provide structural integrity.

Conclusion

Building custom frames with 80/20 aluminum extrusions is a rewarding endeavor that allows for creativity and innovation. By utilizing the essential accessories discussed in this article, you can create strong, functional, and aesthetically pleasing structures tailored to your specific needs. Whether you are a DIY enthusiast or a professional engineer, understanding the importance of these accessories will enhance your projects and ensure their success.

Frequently Asked Questions

1. What are the advantages of using aluminum extrusions over other materials?

- Aluminum extrusions are lightweight, strong, corrosion-resistant, and easy to assemble, making them ideal for a wide range of applications.

2. Can I modify my aluminum frame after it is built?

- Yes, one of the key benefits of using 80/20 aluminum extrusions is their modularity, allowing for easy modifications and expansions.

3. What tools do I need to assemble an aluminum frame?

- Basic tools such as wrenches, screwdrivers, and saws are typically sufficient. Specialized tools like a miter saw can help with angled cuts.

4. How do I ensure my frame is stable?

- Test the stability of your frame after assembly and reinforce any weak points as needed. Using appropriate connectors and fasteners will also enhance stability.

5. Where can I find custom machining services for aluminum extrusions?

- Many suppliers of 80/20 aluminum extrusions offer custom machining services. Check with your local supplier or online retailers for options.