Content Menu

● Introduction to Aluminum Extrusions

>> Aluminum Extrusion Process

● Key Considerations for Choosing a Hawaii Aluminum Extruder

>> Companies Serving Hawaii

● Industries Served by Aluminum Extrusions

>> Custom Aluminum Extrusions for Specific Applications

● Challenges and Opportunities in Hawaii

>> Sustainability and Environmental Considerations

● Market Trends and Outlook

>> Impact of Technological Advancements

● Conclusion

● Frequently Asked Questions

>> 1. What is the Aluminum Extrusion Process?

>> 2. What Industries Use Aluminum Extrusions?

>> 3. How Do I Choose the Best Hawaii Aluminum Extruder?

>> 4. What Are the Benefits of Using Aluminum Extrusions?

>> 5. Are Aluminum Extrusions Environmentally Friendly?

● Citations:

In the beautiful state of Hawaii, finding the right Hawaii aluminum extruder for your project can be a challenging task. Aluminum extrusions are crucial in various industries, including construction, automotive, and aerospace, due to their versatility and durability. This article will guide you through the process of selecting the best Hawaii aluminum extruder and provide insights into the aluminum extrusion process, highlighting key companies and considerations.

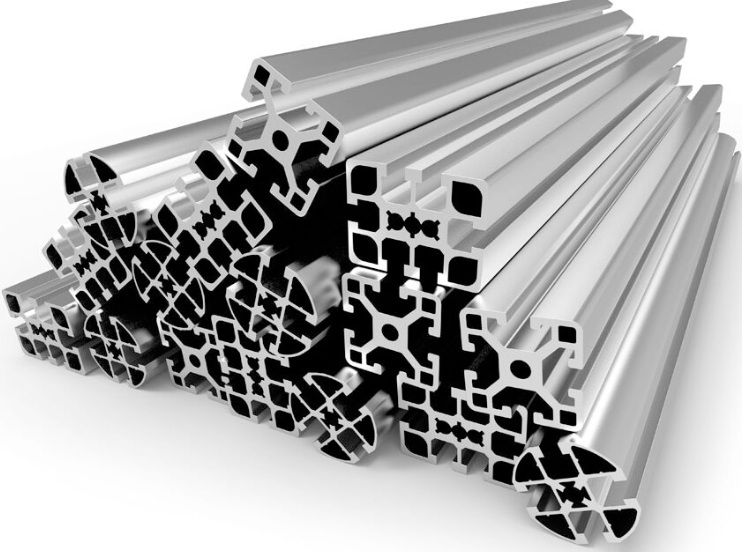

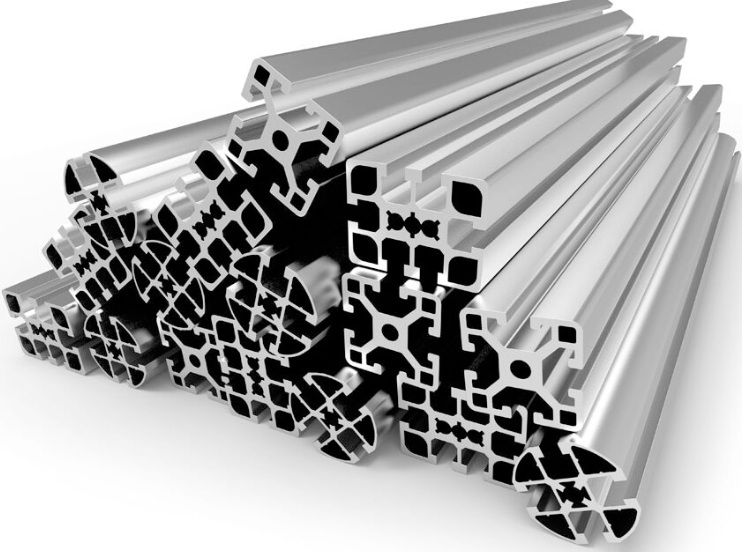

Introduction to Aluminum Extrusions

Aluminum extrusions are created by forcing heated aluminum through a die, which shapes the metal into the desired profile. This process allows for the production of complex shapes with uniform cross-sectional areas, making it ideal for applications such as door and window frames, structural framing systems, and exterior cladding.

Aluminum Extrusion Process

The aluminum extrusion process involves several key steps:

1. Billet Preparation: Aluminum billets are heated to a temperature that softens them without melting.

2. Extrusion: The heated billet is then forced through a die using a hydraulic press, shaping it into the desired profile. The hydraulic ram applies about 15,000 tons of pressure to push the billet through the die[2].

3. Cooling and Treatment: The extruded profile is cooled and may undergo additional treatments like quenching or aging to enhance its properties.

Key Considerations for Choosing a Hawaii Aluminum Extruder

When selecting a Hawaii aluminum extruder, several factors should be considered:

- Quality and Precision: Look for companies that offer high-quality extrusions with tight tolerances.

- Customization Options: Ensure the company can provide custom shapes and profiles tailored to your project needs.

- Secondary Services: Consider companies that offer additional services like CNC machining, anodizing, or powder coating.

- Certifications and Compliance: Check for certifications such as ISO 9001 or AS9100, which ensure adherence to industry standards.

Companies Serving Hawaii

While there may not be many Hawaii aluminum extruders directly located in Hawaii, several companies in nearby states offer services that can be shipped to Hawaii:

- Futura Industries: Located in Utah, Futura Industries is a leading custom aluminum extruder offering a wide range of services including extruding, CNC machining, and anodizing.

- Paramount Extrusions: Based in California, Paramount Extrusions provides custom aluminum extrusions with rapid turnaround times and offers secondary operations like machining and finishing[5].

- Zetwerk: Headquartered in California, Zetwerk supplies custom aluminum extrusions to Hawaii and offers comprehensive logistics services. They provide a range of supplementary services, including powder coating and CNC machining[3].

Industries Served by Aluminum Extrusions

Aluminum extrusions are versatile and serve various industries:

- Construction: Used in building frames, roofing, and exterior cladding.

- Automotive: Employed in vehicle frames and body parts.

- Aerospace: Essential for aircraft structures due to their lightweight and strength.

Custom Aluminum Extrusions for Specific Applications

Companies like Minalex specialize in custom aluminum extrusions for applications such as windows, LED lighting, and aerospace components. They offer precision manufacturing with tight tolerances and various finishes.

Challenges and Opportunities in Hawaii

Hawaii presents unique challenges due to its remote location, which can increase shipping costs and lead times. However, this also creates opportunities for local businesses to develop innovative solutions tailored to the Hawaiian market.

Sustainability and Environmental Considerations

Aluminum extrusions are highly recyclable, making them an environmentally friendly choice. Companies should prioritize sustainable practices and consider the environmental impact of their operations.

Market Trends and Outlook

The global aluminum extrusion market is experiencing significant growth, driven by increasing demand from the construction and automotive sectors. The Asia-Pacific region is a major player in this market, with countries like China leading in aluminum extrusion production[4]. The market is expected to grow further due to advancements in technology and the adoption of sustainable practices[6].

Impact of Technological Advancements

Technological advancements have improved the efficiency and precision of aluminum extrusion processes. For instance, the use of high-speed billets has enhanced extrusion speeds without compromising product strength[6]. These advancements are crucial for meeting the increasing demand for complex and precise aluminum profiles.

Conclusion

Finding the best Hawaii aluminum extruder involves considering factors like quality, customization options, and secondary services. While local options may be limited, companies in nearby states offer comprehensive solutions that can meet the needs of projects in Hawaii. By understanding the aluminum extrusion process and the industries it serves, you can make informed decisions for your project.

Frequently Asked Questions

1. What is the Aluminum Extrusion Process?

The aluminum extrusion process involves heating an aluminum billet and forcing it through a die to create a specific shape. This process is efficient for producing parts with uniform cross-sectional areas.

2. What Industries Use Aluminum Extrusions?

Aluminum extrusions are used in various industries including construction, automotive, aerospace, and electronics due to their strength, durability, and lightweight properties.

3. How Do I Choose the Best Hawaii Aluminum Extruder?

When choosing a Hawaii aluminum extruder, consider factors such as quality, customization capabilities, secondary services offered, and certifications like ISO 9001 or AS9100.

4. What Are the Benefits of Using Aluminum Extrusions?

Aluminum extrusions offer benefits such as high strength-to-weight ratio, corrosion resistance, and recyclability, making them a sustainable choice for many applications.

5. Are Aluminum Extrusions Environmentally Friendly?

Yes, aluminum extrusions are environmentally friendly due to their high recyclability and the fact that aluminum can be recycled infinitely without losing its properties.

Citations:

[1] https://www.ibisworld.com/us/industry/hawaii/aluminum-manufacturing/21090/

[2] https://www.rapiddirect.com/blog/aluminum-extrusion-process/

[3] https://aluminumextrusions.net/usa/hawaii/

[4] https://www.alliedmarketresearch.com/aluminum-extrusion-market-A09001

[5] https://paramountextrusions.com

[6] https://www.giiresearch.com/report/tbrc1658772-aluminum-extruded-products-global-market-report.html

[7] https://www.aerostarmfg.com/machining-capabilities/aluminum-extrusions/

[8] http://www.zycon.com/Products/US-HI-Hawaii/Aluminum-Extrusions.html

[9] https://www.aluminum.org/sites/default/files/2021-11/StateRegionReport3Q2021.pdf

[10] https://www.giiresearch.com/report/imarc1642497-aluminum-extrusion-market-report-by-product-type.html

[11] https://www.beskamold.com/aluminum-extrusion-manufacturers-in-usa/

[12] https://taberextrusions.com/aluminum-extrusions/

[13] https://www.richconn-cnc.com/aluminium-extrusion.html

[14] https://www.giiresearch.com/report/luci1522981-aluminum-extrusion-market-report-trends-forecast.html

[15] https://www.grandviewresearch.com/horizon/outlook/aluminum-extrusion-market/united-states

[16] https://www.minalex.com

[17] https://taberextrusions.com

[18] https://hawaiialuminum.com

[19] https://www.grandviewresearch.com/horizon/outlook/aluminum-extrusion-market-size/global

[20] https://www.reddit.com/r/HotasDIY/comments/xywt4q/where_do_you_find_aluminum_extrusions/