Content Menu

● Introduction to Extrusion Blow Molding Machines

>> Key Features of 60L Automatic Extrusion Blow Molding Machines

● Manufacturers and Suppliers

● Market Trends and Pricing

>> Tips for Finding the Best Deals

● Conclusion

● FAQ

>> 1. What are the typical production capacities of 60L automatic extrusion blow molding machines?

>> 2. What materials can these machines process?

>> 3. How do I ensure energy efficiency in these machines?

>> 4. What kind of after-sales support should I look for?

>> 5. Where can I find reliable suppliers for these machines?

● Citations:

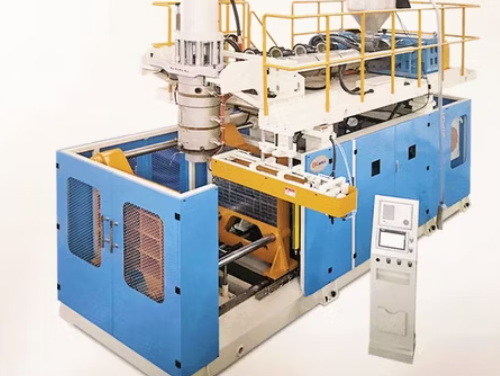

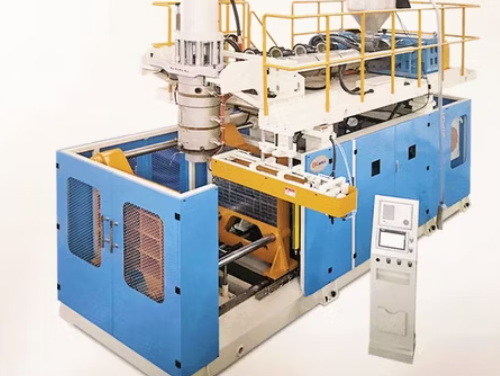

In the rapidly evolving world of plastic manufacturing, finding the best deals on cheap 60L automatic extrusion blow molding machines can be a challenging task. These machines are crucial for producing a wide range of plastic containers, including drums, jerry cans, and barrels. This article will guide you through the process of locating the most cost-effective options for these machines, highlighting key features, manufacturers, and market trends.

Introduction to Extrusion Blow Molding Machines

Extrusion blow molding is a process used to create hollow plastic objects. It involves extruding a tube of plastic (parison) into a mold, where it is then inflated with compressed air to take the shape of the mold. The process is widely used for manufacturing containers such as bottles, drums, and fuel tanks.

Key Features of 60L Automatic Extrusion Blow Molding Machines

When searching for a cheap 60L automatic extrusion blow molding machine, several key features should be considered:

1. Production Capacity: The ability to produce 40-60 pieces per hour is typical for these machines.

2. Material Compatibility: They can process HDPE, PP, and other plastics.

3. Energy Efficiency: Modern machines often incorporate servo hydraulic systems for reduced energy consumption.

4. Automation Level: Fully automatic machines reduce labor costs and improve consistency.

5. After-Sales Support: Comprehensive service packages, including spare parts and technical support, are essential.

Manufacturers and Suppliers

Several manufacturers offer competitive pricing and quality for cheap 60L automatic extrusion blow molding machines:

1. KINGSMAN (China): Known for their high-performance machines with advanced servo systems and comprehensive after-sales support[1].

2. Powerjet (China): Offers a range of extrusion blow molding machines with competitive pricing and customization options[3].

3. DAWSON MACHINE (China): Specializes in energy-efficient machines with advanced automation and customization capabilities[4][9].

Market Trends and Pricing

The market for cheap 60L automatic extrusion blow molding machines is dynamic, with prices influenced by factors such as production capacity, automation level, and energy efficiency. Generally, prices range from $51,500 to $75,000 for machines in the 30-60L capacity range[8].

Tips for Finding the Best Deals

1. Compare Specifications: Ensure that the machine meets your production needs in terms of capacity and material compatibility.

2. Check for Discounts: Look for seasonal promotions or bundle deals that can reduce costs.

3. Evaluate After-Sales Support: Comprehensive service packages can save costs in the long run.

4. Consider Used or Refurbished Machines: These can offer significant savings while still providing reliable performance.

Conclusion

Finding the best deals on cheap 60L automatic extrusion blow molding machines requires careful consideration of key features, market trends, and supplier options. By understanding the specifications and pricing dynamics, manufacturers can make informed decisions that meet their production needs while optimizing costs.

FAQ

1. What are the typical production capacities of 60L automatic extrusion blow molding machines?

Typical production capacities range from 40 to 60 pieces per hour, depending on the machine's configuration and automation level.

2. What materials can these machines process?

These machines can process a variety of plastics, including HDPE, PP, and other polyolefins, making them versatile for different container types.

3. How do I ensure energy efficiency in these machines?

Energy efficiency can be achieved by opting for machines with servo hydraulic systems, which reduce power consumption and improve operational smoothness.

4. What kind of after-sales support should I look for?

Comprehensive after-sales support should include free spare parts, online support, field installation, commissioning, and training, as well as maintenance and repair services.

5. Where can I find reliable suppliers for these machines?

Reliable suppliers can be found through online marketplaces like Alibaba, IndiaMART, and by contacting manufacturers directly, such as KINGSMAN and DAWSON MACHINE.

Citations:

[1] https://www.kingsman-blowtech.com/quality-12154071-hdpe-plastic-drum-blow-molding-machine-60l-drum-extrusion-blow-molding-machine

[2] https://dir.indiamart.com/chennai/blow-molding-machines.html

[3] https://powerjet.en.alibaba.com/productgrouplist-817550631/EB_Extrusion_Blow_Molding_Machines.html

[4] https://www.dawson-plastic.com/Extrusion-Blow-Molding-Machine-for-Hospital-Bed-Plastic-Boards-HDPE-PP-Head-Board-Leg-Board-Making-Blow-Moulding-Machine-pd777111788.html

[5] https://www.greatplast.com/product/blow-molding-machine-60l/

[6] https://www.qenos.com/internet/home.nsf/web/RHAT-96ETFY

[7] https://www.yankangmachine.com/blow-molding-machine-faq/

[8] https://www.meper-blowmolding.com/blow-molding-machine-price/

[9] https://www.dawson-plastic.com/50-120L-50L-60L-100L-HDPE-Plastic-Drum-Making-Accumulator-Die-Head-Fixed-Station-Automatic-Extrusion-Blow-Molding-Machine-pd737441988.html

[10] https://www.alibaba.com/showroom/60l-blow-molding-machine.html

[11] https://www.alibaba.com/product-detail/Hot-sale-extrusion-blow-moulding-machine_1601323306952.html

[12] https://www.alibaba.com/showroom/hdpe-60l-extrusion-blow-molding-machine.html

[13] https://longsnmachine.en.made-in-china.com/product/OxApzbMdnlWc/China-50-Liter-60L-Plastic-Drum-Making-Machine-Jerry-Can-Blow-Molding-Machine-Extrusion-Blow-Moulding-Machine.html

[14] https://apollomachine.en.made-in-china.com/product/xKhJEqFTTmrG/China-Cheap-Price-Good-Quality-40L-50L-60L-Drum-Jerry-Can-Automatic-Blow-Molding-Machine-Made-in-China.html

[15] https://m.kingsman-blowtech.com/sale-12154071-hdpe-plastic-drum-blow-molding-machine-60l-drum-extrusion-blow-molding-machine.html

[16] https://www.alibaba.com/showroom/60l-extrusion-blow-molding-machine.html

[17] https://www.made-in-china.com/manufacturers/automatic-extrusion-blow-molding-machine.html