Content Menu

● Introduction to Aluminum Extrusion

● Understanding Aluminum Extrusion

>> Benefits of Aluminum Extrusion

● Aluminum Extrusion Suppliers: Finding the Right Partner

>> Key Factors in Choosing a Supplier

● Custom Aluminum Profiles: Tailoring to Your Needs

>> Advantages of Custom Profiles

● Local Metal Fabricators: The Convenience of Proximity

>> Benefits of Working with Local Fabricators

● Industrial Aluminum Distributors: Wide Selection and Expertise

>> What to Expect from Distributors

● Extruded Aluminum Manufacturers: Direct from the Source

>> Advantages of Direct Manufacturing Relationships

● Aluminum Framing Systems: Modular Solutions

>> Applications of Aluminum Framing Systems

● Architectural Aluminum Solutions: Aesthetics Meet Functionality

>> Common Architectural Applications

● Metal Extrusion Services: Beyond Aluminum

>> Other Extrudable Metals

● Aluminum Building Materials: Sustainable Construction

>> Advantages in Construction

● Precision Aluminum Components: Meeting Tight Tolerances

>> Industries Relying on Precision Components

● How to Find the Best Aluminum Extrusion Source Near You

● Factors to Consider When Buying Aluminum Extrusion

● The Future of Aluminum Extrusion

● Conclusion

● Frequently Asked Questions

>> Q1: What is the typical lead time for custom aluminum extrusions?

>> Q2: How do I determine the right aluminum alloy for my extrusion project?

>> Q3: Can aluminum extrusions be recycled?

>> Q4: What finishing options are available for aluminum extrusions?

>> Q5: How do I ensure the quality of aluminum extrusions from a new supplier?

Introduction to Aluminum Extrusion

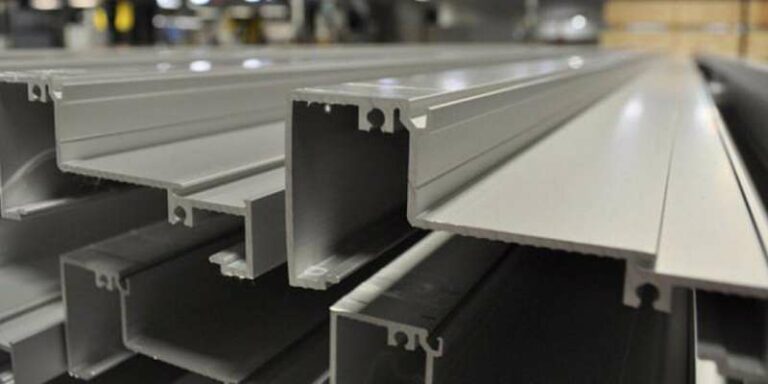

Aluminum extrusion is a versatile and widely used manufacturing process that shapes aluminum alloys into specific cross-sectional profiles. This technique is essential in various industries, including construction, automotive, aerospace, and consumer goods. If you're wondering "Where To Buy Aluminum Extrusion Near Me?", you're not alone. Many businesses and individuals seek local sources for aluminum extrusion to meet their project needs efficiently.

Understanding Aluminum Extrusion

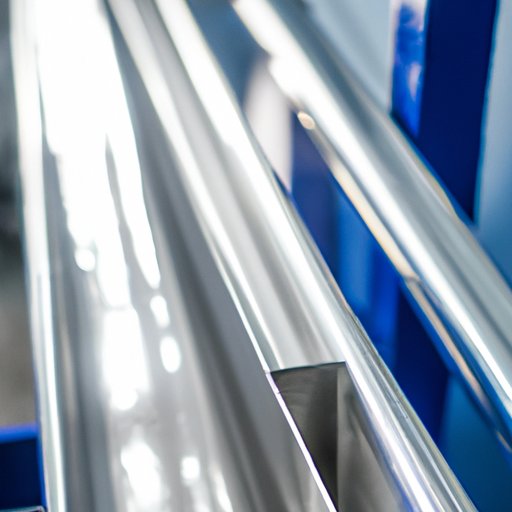

Before diving into where to purchase aluminum extrusion, it's crucial to understand what it is and its applications. Aluminum extrusion involves forcing heated aluminum through a die with a specific cross-sectional profile. The result is a length of material with a consistent shape that can be cut and finished according to specific requirements.

Benefits of Aluminum Extrusion

1. Lightweight yet strong

2. Corrosion-resistant

3. Excellent thermal and electrical conductivity

4. Easily customizable shapes and sizes

5. Cost-effective for both small and large production runs

Aluminum Extrusion Suppliers: Finding the Right Partner

When searching for Aluminum Extrusion Suppliers, consider factors such as product quality, customization options, and delivery times. Local suppliers often offer advantages like faster turnaround times and easier communication.

Key Factors in Choosing a Supplier

1. Experience and reputation in the industry

2. Range of aluminum alloys available

3. Capacity to handle your order volume

4. Quality certifications (e.g., ISO 9001)

5. Technical support and design assistance

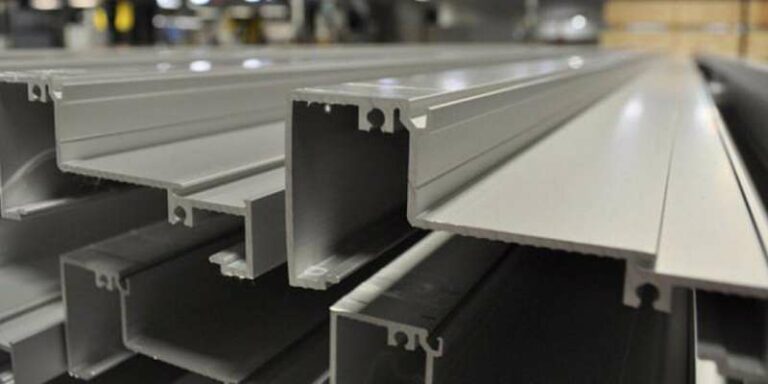

Custom Aluminum Profiles: Tailoring to Your Needs

Many projects require Custom Aluminum Profiles that aren't available off-the-shelf. Working with a supplier who offers customization services can be crucial for specialized applications.

Advantages of Custom Profiles

1. Optimized design for specific applications

2. Reduced material waste

3. Improved functionality and aesthetics

4. Potential cost savings in assembly and production

Local Metal Fabricators: The Convenience of Proximity

Local Metal Fabricators can be an excellent source for aluminum extrusion, especially for smaller orders or projects requiring quick turnaround. They often provide additional services like cutting, drilling, and assembly.

Benefits of Working with Local Fabricators

1. Face-to-face consultations

2. Quicker response times

3. Reduced shipping costs and times

4. Support for the local economy

Industrial Aluminum Distributors: Wide Selection and Expertise

Industrial Aluminum Distributors typically offer a broad range of aluminum products, including various extrusion profiles. They can be an excellent one-stop-shop for all your aluminum needs.

What to Expect from Distributors

1. Extensive inventory of standard profiles

2. Access to multiple manufacturers

3. Value-added services like cutting and finishing

4. Technical knowledge and product recommendations

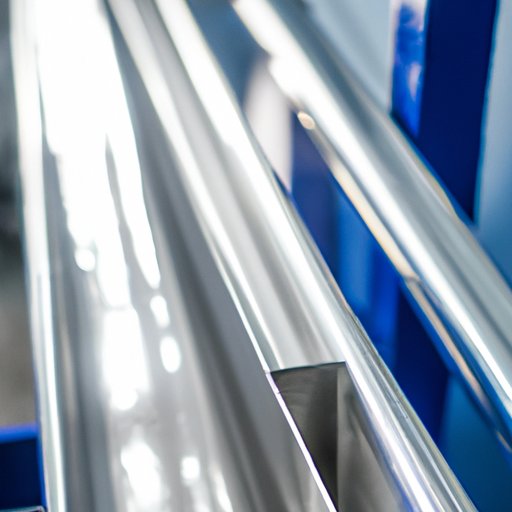

Extruded Aluminum Manufacturers: Direct from the Source

For large-scale projects or highly specialized needs, working directly with Extruded Aluminum Manufacturers can be advantageous. These companies have the capability to produce custom extrusions and often offer design support.

Advantages of Direct Manufacturing Relationships

1. Customization from the extrusion process onward

2. Potential for better pricing on large orders

3. Access to the latest aluminum alloys and technologies

4. Collaborative design and engineering support

Aluminum Framing Systems: Modular Solutions

Aluminum Framing Systems are popular in various industries for their versatility and ease of assembly. These systems often use standardized extrusion profiles that can be easily connected and reconfigured.

Applications of Aluminum Framing Systems

1. Industrial workstations and equipment enclosures

2. Trade show displays and exhibits

3. Clean room partitions

4. Automated manufacturing systems

Architectural Aluminum Solutions: Aesthetics Meet Functionality

In the construction and design industries, Architectural Aluminum Solutions play a significant role. These specialized extrusions are designed to meet both aesthetic and functional requirements for buildings and structures.

Common Architectural Applications

1. Window and door frames

2. Curtain wall systems

3. Sunshades and light shelves

4. Decorative facades and cladding

Metal Extrusion Services: Beyond Aluminum

While aluminum is the most common material for extrusion, Metal Extrusion Services often work with other metals as well. This can be beneficial if your project requires a combination of materials or if you're comparing aluminum to other options.

Other Extrudable Metals

1. Copper and copper alloys

2. Brass

3. Bronze

4. Zinc alloys

Aluminum Building Materials: Sustainable Construction

The construction industry increasingly turns to Aluminum Building Materials for their sustainability and performance characteristics. Extruded aluminum profiles are integral to many modern building systems.

Advantages in Construction

1. High strength-to-weight ratio

2. Recyclability and long lifespan

3. Low maintenance requirements

4. Design flexibility for energy-efficient buildings

Precision Aluminum Components: Meeting Tight Tolerances

For industries requiring high-precision parts, such as aerospace or medical devices, Precision Aluminum Components are essential. These extrusions are manufactured to meet extremely tight tolerances and often undergo additional machining processes.

Industries Relying on Precision Components

1. Aerospace and defense

2. Medical and laboratory equipment

3. Robotics and automation

4. High-performance automotive parts

How to Find the Best Aluminum Extrusion Source Near You

1. Use online directories and search engines to identify local suppliers

2. Check industry associations for member listings

3. Attend trade shows and industry events

4. Ask for recommendations from colleagues or related businesses

5. Utilize social media platforms to connect with manufacturers and distributors

Factors to Consider When Buying Aluminum Extrusion

1. Quality and consistency of the product

2. Lead times and delivery schedules

3. Minimum order quantities

4. Available alloys and finishes

5. Technical support and design assistance

6. Pricing and payment terms

7. Environmental and sustainability practices

The Future of Aluminum Extrusion

The aluminum extrusion industry continues to evolve, driven by technological advancements and changing market demands. Some trends to watch include:

1. Increased use of recycled aluminum in extrusions

2. Development of stronger and more specialized aluminum alloys

3. Integration of smart technologies in extrusion processes

4. Growing demand in emerging markets and industries

Conclusion

Finding the right source for aluminum extrusion near you involves considering various factors, from the type of supplier to the specific requirements of your project. Whether you choose to work with local metal fabricators, industrial distributors, or directly with manufacturers, understanding your needs and the capabilities of potential suppliers is key to a successful partnership.

As the aluminum extrusion industry continues to innovate and expand, staying informed about new developments and maintaining relationships with reliable suppliers will help ensure that you always have access to the materials and expertise needed for your projects.

Frequently Asked Questions

Q1: What is the typical lead time for custom aluminum extrusions?

A1: Lead times for custom aluminum extrusions can vary widely depending on the complexity of the design, the quantity ordered, and the current workload of the manufacturer. Generally, you can expect lead times ranging from 2-8 weeks for custom extrusions. Simple designs with standard alloys might be completed more quickly, while complex profiles or large orders may take longer. It's always best to discuss lead times with your chosen supplier early in the process.

Q2: How do I determine the right aluminum alloy for my extrusion project?

A2: Choosing the right aluminum alloy depends on several factors, including the intended application, required strength, corrosion resistance needs, and cost considerations. Some common alloys used in extrusion include:

- 6061: Good strength and corrosion resistance, widely used in structural applications

- 6063: Excellent for architectural applications due to its finish quality

- 7075: High-strength alloy often used in aerospace applications

Consult with your extrusion supplier or a materials engineer to determine the best alloy for your specific needs. They can help balance performance requirements with cost and availability.

Q3: Can aluminum extrusions be recycled?

A3: Yes, aluminum extrusions are 100% recyclable without loss of quality. In fact, recycling aluminum requires only about 5% of the energy needed to produce new aluminum from raw materials. Many extrusion manufacturers use a significant percentage of recycled aluminum in their products. When your aluminum extrusions reach the end of their useful life, they can be recycled again, making them an environmentally friendly choice for many applications.

Q4: What finishing options are available for aluminum extrusions?

A4: There are several finishing options available for aluminum extrusions, each offering different aesthetic and performance characteristics:

1. Anodizing: Creates a durable, corrosion-resistant surface available in various colors

2. Powder coating: Provides a wide range of colors and textures with excellent durability

3. Painting: Offers unlimited color options but may be less durable than other finishes

4. Brushing or polishing: Creates a metallic luster for a more industrial or modern look

5. Chemical films: Enhances corrosion resistance without changing the metal's appearance

The choice of finish depends on the application, environmental exposure, and aesthetic requirements of your project.

Q5: How do I ensure the quality of aluminum extrusions from a new supplier?

A5: To ensure the quality of aluminum extrusions from a new supplier, consider the following steps:

1. Request and review the supplier's quality certifications (e.g., ISO 9001)

2. Ask for material certifications and test reports for the alloys you're interested in

3. Request samples or prototypes to evaluate before placing a large order

4. Visit the supplier's facility if possible to observe their processes and quality control measures

5. Check references or case studies from other customers in similar industries

6. Establish clear quality expectations and tolerances in your purchase agreement

7. Implement an incoming quality inspection process for received materials

By taking these precautions, you can build confidence in a new supplier's ability to meet your quality requirements consistently.