Content Menu

● Introduction to 2020 Aluminum Extrusion

● Understanding 2020 Aluminum Extrusion

● Applications of 2020 Aluminum Extrusion

● Aluminum Extrusion Suppliers: Where to Buy

>> 1. Online Marketplaces

>> 2. Specialized Retailers

>> 3. Local Industrial Suppliers

>> 4. Direct from Manufacturers

● Factors to Consider When Buying 2020 Aluminum Extrusion

>> 1. Quality and Tolerance

>> 2. Finish Options

>> 3. Length and Customization

>> 4. Compatibility

>> 5. Price and Minimum Order Quantities

● DIY Aluminum Extrusion Kits: A Popular Option

● Modular Framing Systems: Beyond Basic Extrusions

● Structural Aluminum Beams: Load-Bearing Applications

● CNC Aluminum Extrusions: Precision Manufacturing

● Precision Aluminum Components: Beyond Standard Profiles

● The Future of Aluminum Extrusion

● Conclusion

● Frequently Asked Questions

>> Q1: What does "2020" mean in aluminum extrusion?

>> Q2: Can I cut 2020 aluminum extrusion myself?

>> Q3: Are 2020 aluminum extrusions strong enough for load-bearing applications?

>> Q4: How do I join 2020 aluminum extrusions?

>> Q5: Can I paint or anodize 2020 aluminum extrusion?

Introduction to 2020 Aluminum Extrusion

Aluminum extrusion is a versatile and widely used manufacturing process that creates profiles with consistent cross-sections. Among the various sizes and configurations available, the 2020 aluminum extrusion has gained significant popularity in various industries. This guide will explore where to buy 2020 aluminum extrusion, its applications, and essential considerations for purchasers.

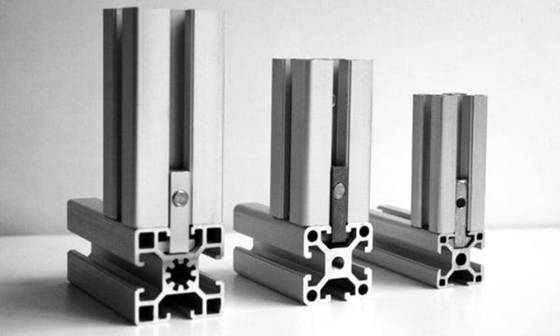

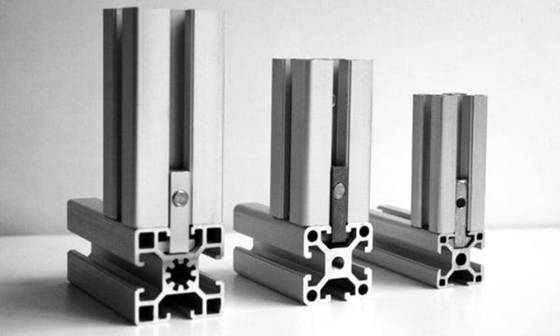

Understanding 2020 Aluminum Extrusion

The term "2020" in aluminum extrusion refers to the profile's dimensions, typically 20mm x 20mm. This size offers a balance between strength and versatility, making it suitable for a wide range of applications. The 2020 profile is part of the broader category of T-slot aluminum extrusions, which feature slots along their length for easy assembly and modification.

Applications of 2020 Aluminum Extrusion

The versatility of 2020 aluminum extrusion makes it an excellent choice for various projects and industries:

1. 3D Printing: Many 3D printer frames utilize 2020 extrusions for their rigidity and ease of customization.

2. CNC Machines: DIY enthusiasts and small-scale manufacturers often use 2020 profiles in building custom CNC machines.

3. Industrial Automation: The profiles are ideal for creating modular framing systems in automated production lines.

4. Furniture Making: Designers use 2020 extrusions to create modern, minimalist furniture pieces.

5. Exhibition Stands: The ease of assembly and disassembly makes 2020 profiles perfect for temporary structures at trade shows.

6. Laboratory Equipment: Research facilities often use these profiles for creating custom workstations and equipment supports.

Aluminum Extrusion Suppliers: Where to Buy

When looking for Aluminum Extrusion Suppliers, several options are available to consumers and businesses alike. Here are some of the most popular sources:

1. Online Marketplaces

Platforms like Amazon, eBay, and AliExpress offer a wide selection of 2020 aluminum extrusions. These marketplaces often provide competitive pricing and the convenience of user reviews to guide your purchase decision.

2. Specialized Retailers

Companies like 80/20 Inc., Misumi, and OpenBuilds specialize in T-Slot 2020 Profiles and other aluminum extrusion products. These retailers often offer high-quality products and excellent customer support.

3. Local Industrial Suppliers

Many cities have local Industrial Aluminum Framing suppliers that stock 2020 extrusions. Buying locally can reduce shipping costs and allow for immediate pickup.

4. Direct from Manufacturers

Some Extruded Aluminum Manufacturers sell directly to consumers, especially for bulk orders. This option can be cost-effective for large projects or businesses requiring a steady supply.

Factors to Consider When Buying 2020 Aluminum Extrusion

Before making a purchase, consider the following factors to ensure you're getting the right product for your needs:

1. Quality and Tolerance

The precision of the extrusion process affects the final product's quality. High-quality extrusions will have tighter tolerances, ensuring better fit and performance in your projects.

2. Finish Options

2020 aluminum extrusions are available in various finishes, including:

- Mill finish (raw aluminum)

- Anodized (for increased corrosion resistance and aesthetic appeal)

- Powder-coated (for color options and additional protection)

Choose a finish that suits both the functional and aesthetic requirements of your project.

3. Length and Customization

Consider whether you need standard lengths or Custom Aluminum Profiles cut to size. Some suppliers offer cutting services, while others may require you to purchase full lengths and cut them yourself.

4. Compatibility

Ensure that the 2020 extrusion you're purchasing is compatible with other components in your project, such as connectors, fasteners, and accessories.

5. Price and Minimum Order Quantities

Compare prices across different suppliers, but also consider minimum order quantities. Bulk purchases often come with discounts but may not be suitable for small-scale projects.

DIY Aluminum Extrusion Kits: A Popular Option

For those embarking on specific projects, DIY Aluminum Extrusion Kits can be an excellent choice. These kits typically include:

- Pre-cut 2020 aluminum extrusions

- Necessary connectors and fasteners

- Assembly instructions

Popular applications for these kits include:

- 3D printer frames

- CNC machine builds

- Custom workbenches

Modular Framing Systems: Beyond Basic Extrusions

Modular Framing Systems based on 2020 aluminum extrusions offer enhanced flexibility and scalability for industrial applications. These systems typically include:

1. A range of profile sizes (including 2020)

2. Specialized connectors and joints

3. Accessories like hinges, wheels, and panels

The modularity of these systems allows for easy reconfiguration and expansion, making them ideal for evolving industrial environments.

Structural Aluminum Beams: Load-Bearing Applications

While 2020 profiles are versatile, some applications require stronger Structural Aluminum Beams. These larger profiles, often based on the same T-slot design, can handle heavier loads and span greater distances. Consider these for:

- Large machine frames

- Overhead gantries

- Heavy-duty workstations

CNC Aluminum Extrusions: Precision Manufacturing

For projects requiring high precision, CNC Aluminum Extrusions offer an excellent solution. These extrusions are machined to tight tolerances using computer-controlled equipment, ensuring:

1. Exact dimensions

2. Smooth surfaces

3. Precise hole placements

CNC-machined extrusions are particularly useful in applications like:

- Robotics

- Aerospace components

- High-precision instruments

Precision Aluminum Components: Beyond Standard Profiles

Some projects may require Precision Aluminum Components that go beyond standard extrusions. Many suppliers offer custom extrusion services, allowing you to design profiles tailored to your specific needs. This can include:

1. Complex cross-sections

2. Integrated functional features

3. Specialized alloys for specific performance requirements

The Future of Aluminum Extrusion

As technology advances, we can expect to see innovations in aluminum extrusion technology, including:

1. Advanced alloys with improved strength-to-weight ratios

2. Smart extrusions with integrated sensors or conductive properties

3. More sustainable manufacturing processes and recycling initiatives

These developments will likely expand the applications of 2020 and other aluminum extrusions across various industries.

Conclusion

2020 aluminum extrusion is a versatile and valuable component in many industries and DIY projects. By understanding where to buy these profiles and what factors to consider, you can ensure that you're getting the right product for your needs. Whether you're building a 3D printer, creating industrial automation systems, or designing modern furniture, 2020 aluminum extrusion offers the flexibility and strength to bring your ideas to life.

Frequently Asked Questions

Q1: What does "2020" mean in aluminum extrusion?

A1: In aluminum extrusion, "2020" refers to the profile's dimensions, typically 20mm x 20mm. This size offers a good balance of strength and versatility for various applications.

Q2: Can I cut 2020 aluminum extrusion myself?

A2: Yes, you can cut 2020 aluminum extrusion yourself using appropriate tools such as a miter saw with a blade designed for cutting aluminum. However, for precise cuts or large quantities, it's often better to purchase pre-cut lengths or use a professional cutting service.

Q3: Are 2020 aluminum extrusions strong enough for load-bearing applications?

A3: While 2020 extrusions are suitable for many applications, their load-bearing capacity depends on the specific use case. For heavy loads or long spans, larger profiles or additional support may be necessary. Always consult engineering guidelines or a professional for load-bearing applications.

Q4: How do I join 2020 aluminum extrusions?

A4: There are several methods to join 2020 aluminum extrusions:

1. T-slot nuts and bolts

2. Corner brackets

3. Specialized connectors designed for the profile

4. Welding (for permanent connections)

The best method depends on your specific application and whether you need the ability to disassemble the structure later.

Q5: Can I paint or anodize 2020 aluminum extrusion?

A5: Yes, 2020 aluminum extrusions can be painted or anodized. Anodizing is an electrochemical process that creates a durable, corrosion-resistant surface and can be done in various colors. Painting is also possible, but proper surface preparation is crucial for good adhesion. Many suppliers offer pre-anodized or powder-coated extrusions if you prefer not to do this yourself.