Content Menu

● Understanding Aluminum Extrusion Clamps

>> Types of Aluminum Extrusion Clamps

● Applications of Aluminum Extrusion Clamps

● Factors to Consider When Choosing Aluminum Extrusion Clamps

>> 1. Compatibility

>> 2. Load Capacity

>> 3. Ease of Installation

>> 4. Material and Finish

>> 5. Price and Value

>> 6. Corrosion Resistance

>> 7. Adjustability

>> 8. Brand Reputation

● Where to Find the Best Aluminum Extrusion Clamps

>> 1. Online Marketplaces

>> 2. Specialized Retailers

>> 3. Industrial Supply Companies

>> 4. Local Hardware Stores

>> 5. Manufacturer Websites

>> 6. Maker Spaces and Hackerspaces

>> 7. 3D Printing Services

>> 8. Surplus Stores

● Tips for Using Aluminum Extrusion Clamps Effectively

● DIY Projects Using Aluminum Extrusion Clamps

>> 1. Custom 3D Printer Enclosure

>> 2. Modular Workbench

>> 3. Photography Lightbox

>> 4. Home Gym Equipment

>> 5. Automated Plant Growing System

>> 6. Racing Simulator Rig

>> 7. Portable Trade Show Booth

>> 8. DIY CNC Router

● Maintenance and Care of Aluminum Extrusion Clamps

● Future Trends in Aluminum Extrusion Clamps

● Conclusion

● Frequently Asked Questions

>> 1. What is the difference between T-slot clamps and corner brackets?

>> 2. Can I use aluminum extrusion clamps for outdoor projects?

>> 3. How do I determine the correct size of clamps for my aluminum extrusions?

>> 4. Are there any alternatives to traditional aluminum extrusion clamps?

>> 5. How much weight can aluminum extrusion clamps support?

Aluminum extrusion clamps are essential tools for DIY enthusiasts and professionals working with aluminum profiles. These versatile components play a crucial role in securing and joining aluminum extrusions, allowing for the creation of sturdy and customizable structures. In this comprehensive guide, we'll explore the world of aluminum extrusion clamps, their applications, and where to find the best options for your DIY projects.

Understanding Aluminum Extrusion Clamps

Aluminum extrusion clamps are specialized fasteners designed to securely hold aluminum profiles together. They come in various shapes and sizes, each tailored to specific applications and extrusion types. These clamps are essential for creating strong, stable connections between aluminum extrusions without the need for welding or permanent modifications.

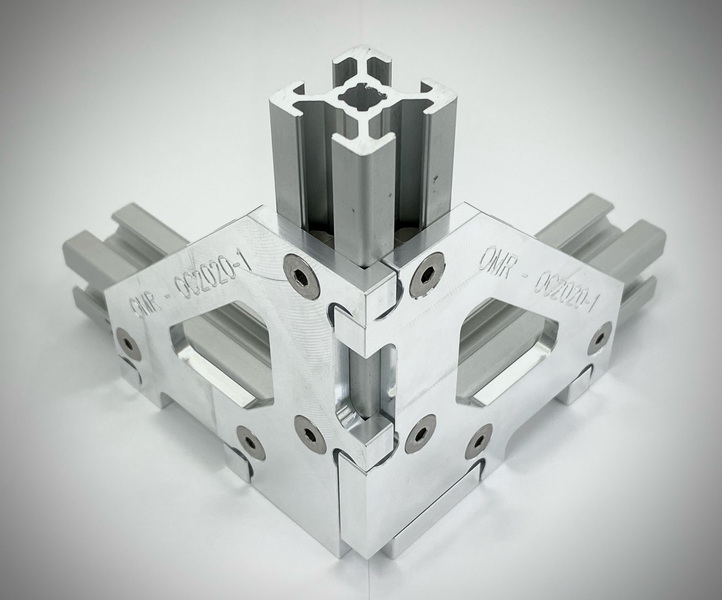

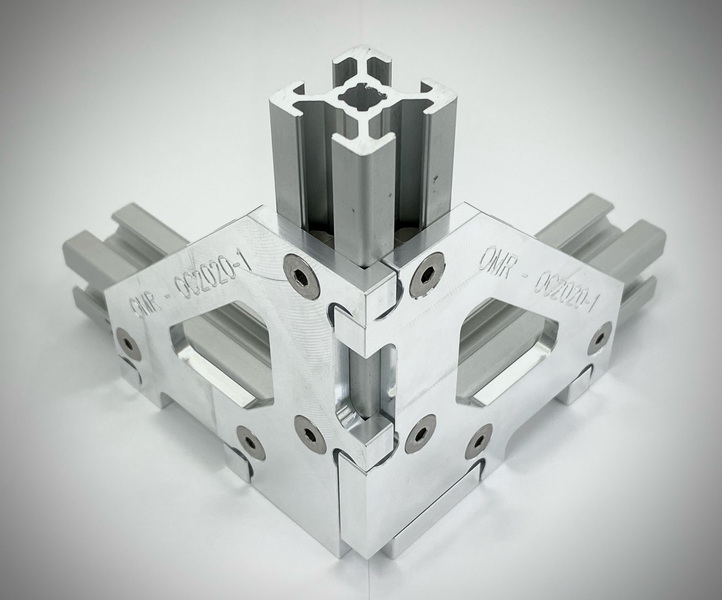

Types of Aluminum Extrusion Clamps

1. T-slot Clamps: These clamps slide into the T-shaped channels of aluminum extrusions, providing a secure grip without damaging the profile.

2. Corner Brackets: Ideal for joining extrusions at right angles, corner brackets offer both strength and aesthetic appeal.

3. Pivot Clamps: These allow for adjustable connections, enabling you to create hinged or movable joints in your structures.

4. End Connectors: Used to join extrusions end-to-end, these clamps ensure a seamless connection between profiles.

5. Quick-Release Clamps: Perfect for temporary installations or frequent reconfigurations, these clamps allow for easy assembly and disassembly.

6. Gusset Brackets: These triangular-shaped brackets provide additional support and rigidity to corner joints, especially useful in load-bearing applications.

7. Angle Brackets: Similar to corner brackets but designed for non-90-degree angles, allowing for more diverse structural designs.

8. Sliding Brackets: These brackets can be adjusted along the length of an extrusion, offering flexibility in positioning and support.

Aluminum Extrusion Clamp Types

Applications of Aluminum Extrusion Clamps

Aluminum extrusion clamps find applications in various industries and DIY projects:

1. 3D Printer Frames: Many 3D printer enthusiasts use aluminum extrusions and clamps to build custom printer frames, ensuring stability and precision.

2. CNC Machine Builds: DIY CNC machine builders often rely on aluminum extrusions and clamps for creating robust and customizable machine frames.

3. Workbenches and Tables: Clamps allow for the easy assembly of sturdy workbenches and tables with adjustable heights and configurations.

4. Display Stands: Trade show displays and retail fixtures often utilize aluminum extrusions and clamps for their versatility and ease of assembly.

5. Home Automation Projects: Smart home enthusiasts use aluminum extrusions and clamps to create custom enclosures and mounting solutions for their devices.

6. Robotics Prototyping: The modular nature of aluminum extrusions and clamps makes them ideal for building and iterating robotic designs quickly.

7. Automotive Accessories: Custom car enthusiasts use aluminum extrusions and clamps to create unique accessories like roof racks or interior organizers.

8. Greenhouse Construction: The corrosion-resistant properties of aluminum make these clamps perfect for building durable greenhouse structures.

9. Photographic Equipment: Photographers use aluminum extrusions and clamps to create custom lighting rigs, backdrops, and camera mounts.

<video src="https://example.com/aluminum-extrusion-clamp-applications.mp4" controls></video>

Factors to Consider When Choosing Aluminum Extrusion Clamps

When selecting the best aluminum extrusion clamps for your DIY projects, consider the following factors:

1. Compatibility

Ensure that the clamps you choose are compatible with the size and profile of your aluminum extrusions. Most clamps are designed for specific extrusion series, such as 2020, 3030, or 4040.

2. Load Capacity

Consider the weight and forces that your structure will need to withstand. Choose clamps with appropriate load ratings to ensure the stability and safety of your project.

3. Ease of Installation

Look for clamps that are easy to install and adjust. Some clamps require special tools, while others can be tightened by hand or with common tools.

4. Material and Finish

High-quality aluminum extrusion clamps are typically made from durable materials like stainless steel or anodized aluminum. Consider the finish of the clamps, especially if aesthetics are important for your project.

5. Price and Value

While it's tempting to opt for the cheapest options, investing in quality clamps can save you time and frustration in the long run. Look for a balance between affordability and durability.

6. Corrosion Resistance

If your project will be exposed to moisture or harsh environments, prioritize clamps with excellent corrosion resistance to ensure longevity.

7. Adjustability

Some clamps offer a range of adjustment, which can be crucial for fine-tuning your structure or accommodating slight variations in extrusion dimensions.

8. Brand Reputation

Consider purchasing clamps from reputable brands known for their quality and customer support. Reading user reviews can provide valuable insights into the performance and reliability of different clamp brands.

Aluminum Extrusion Clamp Factors

Where to Find the Best Aluminum Extrusion Clamps

Now that we understand the importance of choosing the right clamps, let's explore some of the best places to find high-quality aluminum extrusion clamps for your DIY projects:

1. Online Marketplaces

Popular online marketplaces like Amazon, eBay, and AliExpress offer a wide variety of aluminum extrusion clamps. These platforms often provide competitive prices and user reviews to help you make informed decisions.

2. Specialized Retailers

Websites dedicated to 3D printing, CNC machining, and DIY projects often stock a range of aluminum extrusion clamps. These retailers may offer expert advice and curated selections tailored to specific applications.

3. Industrial Supply Companies

Companies like McMaster-Carr, Grainger, and Misumi offer extensive catalogs of aluminum extrusion clamps and related components. While prices may be higher, these suppliers often provide high-quality products and detailed technical specifications.

4. Local Hardware Stores

Some well-stocked hardware stores carry aluminum extrusion clamps, especially if there's a demand for DIY and maker projects in your area. The advantage of shopping locally is the ability to see and handle the clamps before purchasing.

5. Manufacturer Websites

Many aluminum extrusion manufacturers sell clamps and accessories directly through their websites. This can be a good option if you're looking for clamps specifically designed for a particular extrusion series.

6. Maker Spaces and Hackerspaces

Local maker spaces or hackerspaces may have connections to suppliers or bulk purchasing options for members. These communities can also provide valuable advice on sourcing and using aluminum extrusion clamps.

7. 3D Printing Services

For custom or unique clamp designs, consider using 3D printing services. While not suitable for all applications, 3D printed clamps can be an excellent solution for specialized or low-load projects.

8. Surplus Stores

Electronics or industrial surplus stores sometimes carry aluminum extrusion clamps at discounted prices. While the selection may be limited, you can often find great deals on high-quality components.

Aluminum Extrusion Clamp Retailers

Tips for Using Aluminum Extrusion Clamps Effectively

To get the most out of your aluminum extrusion clamps, consider these tips:

1. Clean the Extrusions: Ensure that the surfaces of your aluminum extrusions are clean and free from debris before attaching clamps.

2. Use the Right Tools: Some clamps require specific tools for installation. Make sure you have the necessary Allen keys, wrenches, or other tools on hand.

3. Tighten Gradually: When assembling your structure, tighten the clamps gradually and evenly to ensure proper alignment and prevent warping.

4. Check Periodically: Regularly inspect and re-tighten your clamps, especially if your structure is subject to vibration or frequent use.

5. Combine Clamp Types: Don't hesitate to use different types of clamps in your project to achieve the best stability and functionality.

6. Pre-assemble When Possible: For complex structures, try to pre-assemble smaller components before final assembly. This can make the overall construction process easier and more precise.

7. Use Thread-locking Compounds: For applications subject to vibration, consider using thread-locking compounds on the clamp screws to prevent loosening over time.

8. Plan for Future Modifications: When designing your structure, consider how you might need to modify or expand it in the future. Choose clamp configurations that allow for easy adjustments or additions.

9. Document Your Assembly: Take photos or notes during the assembly process. This can be invaluable if you need to disassemble or replicate the structure later.

10. Consider Load Distribution: When using clamps in load-bearing applications, ensure that the weight is distributed evenly across multiple clamps rather than relying on a single point of connection.

DIY Projects Using Aluminum Extrusion Clamps

To inspire your next DIY endeavor, here are some popular projects that make extensive use of aluminum extrusion clamps:

1. Custom 3D Printer Enclosure

Create a professional-looking enclosure for your 3D printer using aluminum extrusions and clamps. This project not only improves the aesthetics of your setup but also helps control temperature and reduce noise.

2. Modular Workbench

Build a versatile workbench with adjustable height and interchangeable surfaces using aluminum extrusions and clamps. This project allows you to customize your workspace for different tasks and tools.

3. Photography Lightbox

Construct a collapsible lightbox for product photography using aluminum extrusions and quick-release clamps. This portable setup can significantly improve your product shots for online listings or portfolios.

4. Home Gym Equipment

Design and build custom gym equipment, such as a squat rack or pull-up bar, using sturdy aluminum extrusions and heavy-duty clamps. This project allows you to create gym equipment tailored to your specific needs and space constraints.

5. Automated Plant Growing System

Develop a vertical hydroponic system using aluminum extrusions and clamps to create a sturdy frame. Incorporate LED grow lights and automated watering systems for a high-tech gardening solution.

6. Racing Simulator Rig

Construct a custom racing simulator setup using aluminum extrusions and clamps. This project allows you to create a rigid frame for mounting steering wheels, pedals, and screens for an immersive racing experience.

7. Portable Trade Show Booth

Design a modular and easily transportable trade show booth using lightweight aluminum extrusions and quick-release clamps. This project showcases the versatility of extrusion systems for creating professional display solutions.

8. DIY CNC Router

Build a robust CNC router frame using aluminum extrusions and heavy-duty clamps. This project demonstrates how extrusion systems can be used to create precise and stable platforms for machining applications.

DIY Projects with Aluminum Extrusion Clamps

Maintenance and Care of Aluminum Extrusion Clamps

To ensure the longevity and performance of your aluminum extrusion clamps, follow these maintenance tips:

1. Regular Cleaning: Wipe down your clamps periodically to remove dust and debris that can affect their performance.

2. Lubrication: Apply a small amount of lubricant to moving parts, such as threads or pivot points, to maintain smooth operation.

3. Proper Storage: Store your clamps in a dry environment to prevent corrosion, especially for steel components.

4. Inspection: Regularly check your clamps for signs of wear or damage, and replace them if necessary.

5. Avoid Overtightening: While it's important to secure your clamps properly, overtightening can damage both the clamps and the aluminum extrusions.

6. Protect from Chemicals: Avoid exposing your clamps to harsh chemicals or solvents that could degrade the materials or finishes.

7. Use Correct Tools: Always use the appropriate tools when installing or adjusting clamps to avoid damaging the fasteners or the clamp itself.

8. Maintain Proper Alignment: Ensure that your extrusions remain properly aligned to prevent undue stress on the clamps and maintain the integrity of your structure.

Future Trends in Aluminum Extrusion Clamps

As DIY and maker communities continue to grow, we can expect to see some exciting developments in aluminum extrusion clamp technology:

1. Smart Clamps: Integration of sensors and wireless connectivity to monitor structural integrity and provide real-time data.

2. 3D Printed Clamps: Custom-designed clamps that can be 3D printed for specific applications or unique extrusion profiles.

3. Eco-Friendly Materials: Development of sustainable and biodegradable materials for clamp production.

4. Improved Ergonomics: Design innovations to make clamps easier to install and adjust, especially for users with limited mobility.

5. Multi-Functional Clamps: Clamps that incorporate additional features such as cable management or integrated leveling systems.

6. Advanced Locking Mechanisms: Development of more secure and user-friendly locking systems that provide enhanced stability without sacrificing ease of use.

7. Composite Materials: Integration of high-strength composite materials to create lighter yet stronger clamps for specialized applications.

8. Augmented Reality Assembly: AR applications that guide users through the process of selecting and installing the right clamps for their projects.

9. Modular Robotics Integration: Clamps designed to easily integrate with modular robotics systems, enabling rapid prototyping and development of robotic applications.

10. Self-Aligning Clamps: Development of clamps with built-in alignment features to ensure perfect positioning and reduce assembly errors.

Conclusion

Aluminum extrusion clamps are versatile and essential components for a wide range of DIY projects. By understanding the different types of clamps available, considering key factors in your selection process, and knowing where to find the best options, you can elevate your DIY game and create professional-quality structures and devices.

Whether you're building a custom 3D printer frame, designing a modular workbench, or creating innovative smart home solutions, the right aluminum extrusion clamps can make all the difference in the success of your project. Remember to prioritize quality, compatibility, and ease of use when choosing your clamps, and don't be afraid to experiment with different types to achieve the best results.

As the maker movement continues to grow and evolve, we can look forward to even more innovative clamp designs and applications in the future. The integration of smart technologies, sustainable materials, and advanced manufacturing techniques promises to make aluminum extrusion clamps even more versatile and user-friendly.

So, grab your aluminum extrusions and clamps, and start bringing your DIY visions to life! With the right tools and knowledge, you can create sturdy, professional-looking projects that showcase your creativity and technical skills. Whether you're a hobbyist or a professional, the world of aluminum extrusion clamps offers endless possibilities for innovation and customization in your DIY endeavors.

Frequently Asked Questions

1. What is the difference between T-slot clamps and corner brackets?

T-slot clamps are designed to slide into the channels of aluminum extrusions, providing a secure connection along the length of the profile. They are versatile and can be used for various joining configurations. Corner brackets, on the other hand, are specifically designed to join two extrusions at right angles, creating strong and precise 90-degree connections. While T-slot clamps offer more flexibility in positioning, corner brackets provide enhanced stability for perpendicular joints.

2. Can I use aluminum extrusion clamps for outdoor projects?

Yes, you can use aluminum extrusion clamps for outdoor projects, but it's important to choose clamps made from corrosion-resistant materials such as stainless steel or anodized aluminum. Additionally, consider applying a protective coating or sealant to the clamps and extrusions to enhance their weather resistance. Regularly inspect and maintain outdoor structures to ensure the clamps remain secure and free from rust or degradation.

3. How do I determine the correct size of clamps for my aluminum extrusions?

To determine the correct size of clamps, you need to know the dimensions of your aluminum extrusions. Most extrusions are categorized by their cross-sectional measurements, such as 2020 (20mm x 20mm) or 4040 (40mm x 40mm). Check the specifications of the clamps to ensure they are compatible with your extrusion size. Some manufacturers provide sizing charts or guides to help you select the appropriate clamps for your specific extrusion profiles.

4. Are there any alternatives to traditional aluminum extrusion clamps?

Yes, there are several alternatives to traditional clamps:

-3D printed connectors: Custom-designed for specific projects

-Welding: For permanent, high-strength connections

-Adhesive bonding: Using specialized structural adhesives

-Bolt-through connections: Drilling and bolting extrusions directly

-Magnetic connectors: For temporary or adjustable assemblies

Each alternative has its pros and cons, so consider your project requirements when choosing a connection method.

5. How much weight can aluminum extrusion clamps support?

The weight capacity of aluminum extrusion clamps varies depending on the type, size, and material of the clamp, as well as the configuration of the structure. Some heavy-duty clamps can support loads of several hundred pounds, while smaller clamps may be limited to a few dozen pounds. Always check the manufacturer's specifications for load ratings and factor in safety margins when designing your structure. For critical applications or heavy loads, consider consulting with a structural engineer to ensure the safety and stability of your design.