Content Menu

● Introduction to Extrusion Equipment

>> Plastic Extrusion

>> Metal Extrusion

● Top Extrusion Equipment Manufacturers

>> Plastic Extrusion Equipment Manufacturers

>> Metal Extrusion Equipment Manufacturers

● Choosing the Right Extrusion Equipment

● Types of Extrusion Machines

>> Single-Screw Extruders

>> Twin-Screw Extruders

● Specialized Extrusion Machines

● Conclusion

● FAQs

>> 1. What are the main types of extrusion machines?

>> 2. How do I choose the right extrusion equipment manufacturer?

>> 3. What are the applications of plastic extrusion?

>> 4. What is the difference between co-rotating and counter-rotating twin-screw extruders?

>> 5. How do I ensure the quality of extruded products?

● Citations:

In the vast and dynamic world of plastic and metal manufacturing, extrusion equipment plays a pivotal role in shaping raw materials into diverse products such as pipes, profiles, films, and more. Finding reliable extrusion equipment manufacturers is crucial for ensuring high-quality output, efficiency, and cost-effectiveness in production processes. This article delves into the key aspects of extrusion equipment, highlights top manufacturers, and provides insights into how to select the best equipment for your needs.

Introduction to Extrusion Equipment

Extrusion is a manufacturing process where raw materials are melted and forced through a die to create products with uniform cross-sections. The process is widely used in both plastic and metal industries. Plastic extrusion, for instance, is essential for producing items like plastic bags, straws, and pipes, while metal extrusion is used for aluminum profiles and other metal parts.

Plastic Extrusion

Plastic extrusion involves melting thermoplastic materials and shaping them into continuous profiles. The process is versatile and can produce a wide range of products, from simple tubes to complex profiles.

Metal Extrusion

Metal extrusion, particularly aluminum extrusion, involves forcing heated metal through a die to create profiles. This process is critical for producing structural components used in construction, automotive, and aerospace industries.

Top Extrusion Equipment Manufacturers

Identifying reliable extrusion equipment manufacturers is essential for ensuring the quality and efficiency of your production line. Here are some of the top manufacturers in the industry:

Plastic Extrusion Equipment Manufacturers

1. Coperion (Germany): Known for advanced compounding systems and twin-screw extruders, Coperion offers custom solutions with a global presence[1][2].

2. YeJing: Offers a wide range of extrusion solutions, including twin-screw extruders for plastics and pharmaceuticals[1][3].

3. Kabra Extrusiontechnik Ltd. (India): Specializes in providing extrusion solutions for various industries[3].

4. Bausano & Figli S.p.A (Italy): Offers comprehensive extrusion machinery for applications like pipe and profile extrusion[1][2].

5. Davis-Standard (USA): Known for its high-quality extrusion systems, including sheet extrusion lines[9].

Metal Extrusion Equipment Manufacturers

While specific metal extrusion equipment manufacturers are less commonly listed alongside plastic extruders, companies like Aluminum Extrusion Companies focus on providing machinery and services for aluminum extrusion processes.

Choosing the Right Extrusion Equipment

When selecting extrusion equipment, several factors should be considered:

- Production Capacity: Ensure the equipment meets your current and future output needs.

- Flexibility and Versatility: Opt for systems that can handle various materials and thicknesses.

- Energy Efficiency: Choose energy-efficient models to reduce operational costs and environmental impact.

- Equipment Reliability and Maintenance: Select reliable equipment with low maintenance needs and strong manufacturer support.

- Output Quality: Ensure the line produces high-quality products suitable for your applications.

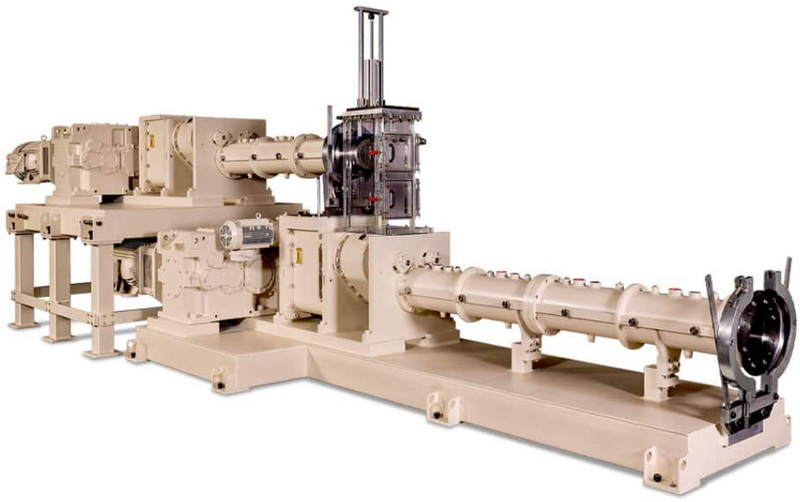

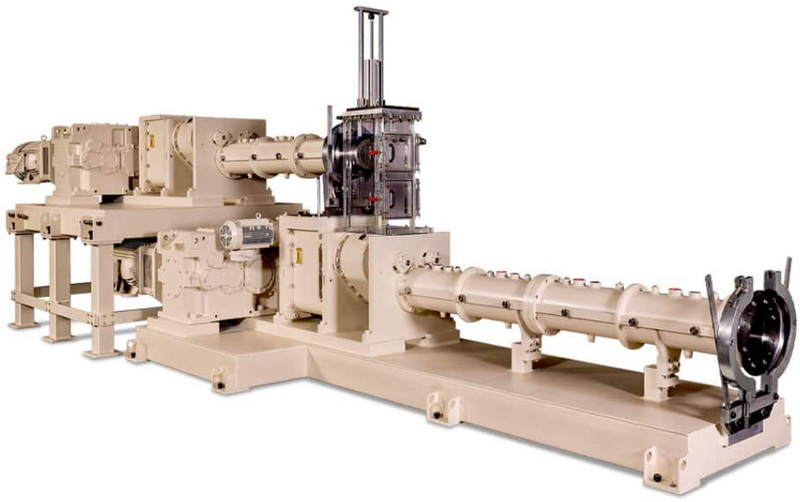

Types of Extrusion Machines

Extrusion machines can be broadly categorized into single-screw and twin-screw extruders.

Single-Screw Extruders

- Advantages: Simple design, easy operation, cost-effective, and suitable for basic extrusion tasks.

- Limitations: Limited mixing efficiency and not ideal for complex materials.

Twin-Screw Extruders

- Advantages: Enhanced mixing and processing capabilities, suitable for a wide variety of materials, and offers better control over the melting process.

- Limitations: More complex design and higher investment costs.

Specialized Extrusion Machines

Different industries require specialized extrusion machines tailored to specific materials and applications:

- PVC Extruders: Designed to handle PVC's sensitivity to temperature fluctuations.

- HDPE Extruders: Engineered for high-density polyethylene, known for its toughness and rigidity.

- PET Extruders: Specialized for polyethylene terephthalate, commonly used in packaging.

Conclusion

Finding reliable extrusion equipment manufacturers is crucial for maintaining high-quality production and efficiency in manufacturing processes. By understanding the types of extrusion machines, their applications, and the key factors to consider when selecting equipment, businesses can optimize their production lines and meet evolving market demands.

FAQs

1. What are the main types of extrusion machines?

Answer: The main types of extrusion machines are single-screw and twin-screw extruders. Single-screw extruders are cost-effective and simple, while twin-screw extruders offer enhanced mixing capabilities and are suitable for complex materials[7].

2. How do I choose the right extrusion equipment manufacturer?

Answer: Consider factors such as production capacity, flexibility, energy efficiency, equipment reliability, and output quality when selecting an extrusion equipment manufacturer[9].

3. What are the applications of plastic extrusion?

Answer: Plastic extrusion is used in various industries for producing pipes, tubing, films, profiles, and more. It is essential in construction, packaging, and manufacturing sectors[7].

4. What is the difference between co-rotating and counter-rotating twin-screw extruders?

Answer: Co-rotating twin-screw extruders are commonly used for compounding and offer better mixing efficiency, while counter-rotating extruders are less common but can be used for specific applications requiring different mixing patterns[2].

5. How do I ensure the quality of extruded products?

Answer: Ensure the quality of extruded products by maintaining precise temperature and pressure controls during the extrusion process, using high-quality raw materials, and regularly inspecting the equipment for optimal performance[7].

Citations:

[1] https://www.kailidaextrusion.com/top-20-plastic-extrusion-machine-manufacturers/

[2] https://ud-machine.com/blog/top-twin-screw-extruder-manufacturers/

[3] https://www.cowellextrusion.com/top-10-plastic-extrusion-machine-manufacturers/

[4] https://www.alamy.com/stock-photo/extrusion-machine.html

[5] https://www.youtube.com/watch?v=Y75IQksBb0M

[6] https://www.youtube.com/watch?v=NSCX6K1eecI

[7] https://jieyatwinscrew.com/blog/everything-you-need-to-know-about-plastic-extrusion-machines/

[8] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[9] https://www.gsextruder.com/top-10-plastic-sheet-extrusion-machine-manufacturers-in-2024/

[10] https://www.conairgroup.com/resources/resource/extrusion-processing-basic-guide-to-auxiliary-equipment/

[11] https://www.jwellextrusions.com/faq/

[12] https://www.blessonextrusion.com/faqs/

[13] https://www.bestextrusion.com/lxfs/list_9.aspx

[14] https://www.sourcifychina.com/top-plastic-extrusion-machine-manufacturers-compare-2/

[15] https://www.alibaba.com/countrysearch/CN/best-extrusion-machine.html

[16] https://jydjx.com/top-20-plastic-extrusion-machine-manufacturers/

[17] https://us.metoree.com/categories/2333/

[18] https://granuwelextruder.com/ko/10-reliable-plastic-extrusion-machine-manufacturers-2024/

[19] https://granuwelextruder.com/10-reliable-plastic-extrusion-machine-manufacturers-2024/

[20] https://ensun.io/search/aluminium-extrusion

[21] https://www.polytechmachine.com/info/top-5-china-plastic-extrusion-machine-manufact-98886068.html

[22] https://www.stcmach.com/e/product.html

[23] https://us.metoree.com/categories/7271/