Content Menu

● Overview of Sarem Pipe Extrusion Machinery

● Types of Pipes Produced by Sarem Pipe Extrusion Machinery

>> 1. PP Pipes (Polypropylene Pipes)

>> 2. PE Pipes (Polyethylene Pipes)

>> 3. PVC Pipes (Polyvinyl Chloride Pipes)

>> 4. PPR-C Pipes (Polypropylene Random Copolymer Pipes)

>> 5. PEX-A Pipes (Cross-linked Polyethylene Pipes)

>> 6. Multilayer Pipes

>> 7. Corrugated Pipes

>> 8. Drip Irrigation Pipes

● Technological Features of Sarem Pipe Extrusion Machinery

● Applications of Pipes Produced by Sarem Machinery

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What polymers can Sarem pipe extrusion machinery process?

>> 2. What is the maximum pipe diameter that Sarem extrusion lines can produce?

>> 3. How does Sarem ensure energy efficiency in its extrusion machinery?

>> 4. Are Sarem's extrusion lines suitable for multilayer pipe production?

>> 5. What industries benefit most from pipes produced by Sarem machinery?

● Citations:

Sarem Machinery, a leading manufacturer based in Istanbul, Turkey, specializes in the production of advanced plastic pipe extrusion machinery. Since its establishment in 1998, Sarem has become a global player in the pipe extrusion industry, supplying over 300 pipe extrusion lines to 44 countries worldwide. Their expertise spans a wide range of pipe types and sizes, supported by cutting-edge technology and a commitment to quality and innovation. This article explores the various types of pipes that Sarem pipe extrusion machinery can produce, highlighting the machinery's capabilities, applications, and technological advantages.

Overview of Sarem Pipe Extrusion Machinery

Sarem pipe extrusion machinery is designed to manufacture a diverse array of plastic pipes with diameters ranging from as small as 16mm up to 1000mm. The company integrates mechanical engineering expertise with modern automation technologies to deliver highly efficient, reliable, and energy-saving extrusion lines. Their production lines include not only the extrusion machines themselves but also downstream equipment such as haul-offs, vacuum tanks, calibration sleeves, belling machines, and automatic coil winders, ensuring complete turnkey solutions for pipe manufacturers[3][4].

Sarem's machinery supports multiple polymer types, including PP (Polypropylene), PE (Polyethylene), PVC (Polyvinyl Chloride), PPR-C (Polypropylene Random Copolymer), PEX-A (Cross-linked Polyethylene), and multilayer pipes. This versatility allows manufacturers to produce pipes tailored for various industrial, agricultural, and construction applications.

Types of Pipes Produced by Sarem Pipe Extrusion Machinery

1. PP Pipes (Polypropylene Pipes)

PP pipes are widely used in plumbing, heating, and industrial applications due to their chemical resistance, durability, and ease of installation. Sarem machinery efficiently produces PP pipes with consistent wall thickness and high dimensional accuracy. These pipes are suitable for hot and cold water systems, chemical transportation, and other demanding environments.

2. PE Pipes (Polyethylene Pipes)

PE pipes are among the most versatile and commonly used plastic pipes globally. Sarem extrusion lines produce PE pipes in various grades, including HDPE (High-Density Polyethylene), which are used extensively for water supply, gas distribution, sewage, and irrigation systems. The machinery ensures excellent surface finish and mechanical properties, meeting international standards.

3. PVC Pipes (Polyvinyl Chloride Pipes)

PVC pipes produced by Sarem machinery are ideal for drainage, sewage, and irrigation applications. The extrusion lines provide precise control over pipe dimensions and surface quality. PVC pipes are favored for their rigidity, chemical resistance, and cost-effectiveness.

4. PPR-C Pipes (Polypropylene Random Copolymer Pipes)

PPR-C pipes are commonly used for potable water and heating systems due to their high temperature and pressure resistance. Sarem's extrusion machinery can produce these pipes with multilayer structures, enhancing their mechanical strength and longevity.

5. PEX-A Pipes (Cross-linked Polyethylene Pipes)

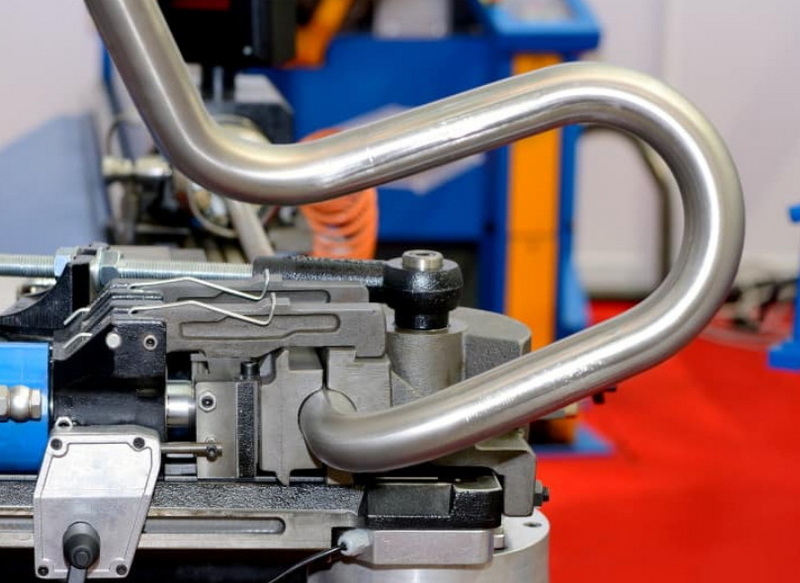

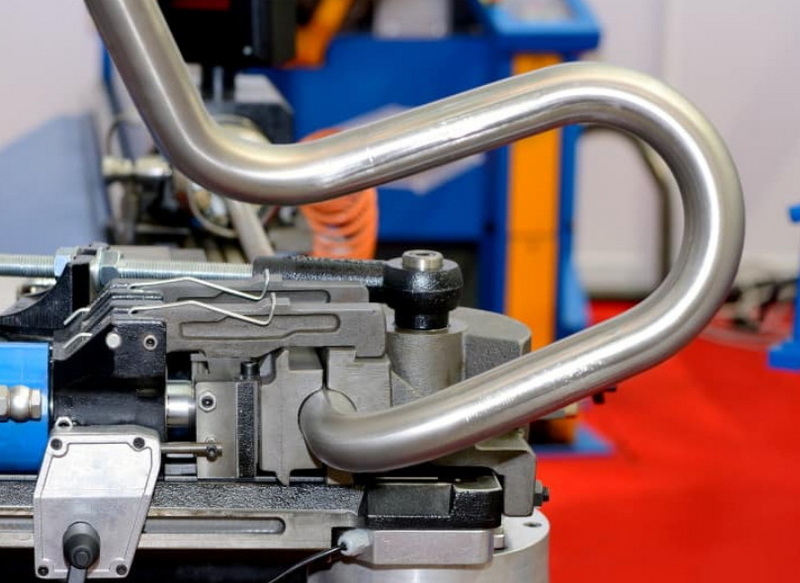

PEX-A pipes are known for their flexibility, durability, and resistance to temperature fluctuations. Sarem Machinery offers the world's only fully integrated PEX-A pipe extrusion solution, which includes a specially designed extruder, infrared (IR) oven for cross-linking, an online dosing system, and automated downstream equipment. This integration ensures superior quality, efficiency, and reliability in PEX-A pipe production, making it suitable for radiant heating, plumbing, and industrial applications[3].

6. Multilayer Pipes

Sarem pipe extrusion machinery can produce multilayer pipes composed of different materials such as PE, EVOH (Ethylene Vinyl Alcohol), and aluminum layers. These multilayer pipes combine the advantages of each material, such as gas barrier properties, mechanical strength, and flexibility. They are widely used in automotive, heating, and potable water systems.

7. Corrugated Pipes

Corrugated pipes are essential for drainage and sewage systems, especially in infrastructure projects requiring flexibility and durability. Sarem's corrugated pipe extrusion lines produce pipes with diameters ranging from 160mm to 400mm, designed to withstand environmental stresses such as earthquakes by allowing flexibility without damage. These pipes are commonly used for transporting rainwater and wastewater from building foundations and streets[2].

8. Drip Irrigation Pipes

Sarem machinery also manufactures extrusion lines for drip irrigation pipes, which are critical in agricultural irrigation systems. These pipes require precise wall thickness and durability to ensure long-term performance under varying environmental conditions. Sarem's fully automatic coil winders enhance production efficiency for these pipe types[3].

Technological Features of Sarem Pipe Extrusion Machinery

Sarem's pipe extrusion machinery incorporates several advanced features that enhance production quality and efficiency:

- High-Output Extruders: Designed for maximum throughput with consistent quality.

- Infrared (IR) Ovens: Used especially in PEX-A pipe production to ensure uniform cross-linking.

- Smart Dosing Systems: Guarantee accurate material flow and mixing.

- Automated Downstream Equipment: Includes haul-offs, vacuum tanks, belling machines, and automatic coil winders that reduce manual labor and increase precision.

- Energy Efficiency: Sarem machines use optimized energy consumption technologies, including hydraulic and pneumatic automation systems, to reduce operational costs[3][4].

Applications of Pipes Produced by Sarem Machinery

The pipes produced by Sarem extrusion lines serve a broad spectrum of industries:

- Water Supply and Distribution: PE, PPR-C, and PVC pipes are widely used for potable water and irrigation.

- Sewage and Drainage: Corrugated and PVC pipes are essential for wastewater management.

- Gas Distribution: HDPE pipes manufactured on Sarem lines are suitable for safe gas transportation.

- Heating and Cooling Systems: PEX-A and multilayer pipes are ideal for radiant heating and cooling applications.

- Agriculture: Drip irrigation pipes enhance water efficiency in farming.

- Industrial Applications: Chemical-resistant PP and PE pipes are used in various industrial processes.

Conclusion

Sarem pipe extrusion machinery offers a comprehensive solution for the production of a wide variety of plastic pipes, including PP, PE, PVC, PPR-C, PEX-A, multilayer, corrugated, and drip irrigation pipes. Their advanced technology, combined with efficient automation and energy-saving features, positions Sarem as a competitive global leader in pipe extrusion machinery manufacturing. Whether for water supply, sewage, gas, or agricultural applications, Sarem's machinery delivers high-quality pipes that meet international standards and diverse customer needs.

Frequently Asked Questions (FAQ)

1. What polymers can Sarem pipe extrusion machinery process?

Sarem machinery can process PP, PE (including HDPE), PVC, PPR-C, PEX-A, and multilayer materials, allowing for a wide range of pipe types suitable for various applications[3].

2. What is the maximum pipe diameter that Sarem extrusion lines can produce?

Sarem pipe extrusion lines can produce pipes with diameters ranging from 16mm up to 1000mm, accommodating both small and large-scale pipe manufacturing needs[3].

3. How does Sarem ensure energy efficiency in its extrusion machinery?

Sarem incorporates optimized hydraulic and pneumatic automation, infrared heating systems, and smart dosing technologies to minimize energy consumption without compromising production quality[4].

4. Are Sarem's extrusion lines suitable for multilayer pipe production?

Yes, Sarem offers machinery capable of producing multilayer pipes, combining different materials like PE, aluminum, and EVOH to enhance pipe properties such as gas barrier and mechanical strength[3].

5. What industries benefit most from pipes produced by Sarem machinery?

Industries including water supply, sewage management, gas distribution, heating and cooling systems, agriculture (drip irrigation), and various industrial sectors benefit from Sarem-produced pipes[3].

Citations:

[1] https://ms.machinery-hitech.com/blog/detail-160755.html

[2] https://www.youtube.com/watch?v=SvnZF9Eh4zY

[3] https://ae.linkedin.com/company/sarem-machinery

[4] https://new.abb.com/drives/highlights-and-references/article-sarem-makina

[5] https://ae.linkedin.com/company/sarem-machinery

[6] https://www.sarem.com.tr/wp-content/uploads/2023/11/Sarem-Catalog-2024.pdf

[7] https://www.sarem.com.tr/en/pp-rc-pipe-production-lines/

[8] https://pdf.directindustry.com/pdf/sarem/plastic-pipe-extrusion-lines/242485-1025688.html

[9] https://www.plantautomation-technology.com/public/index.php/products/sarem-machinery/extruders

[10] https://plasteurasia.com/en/exhibitor-list/sarem-makina-san-ve-tic-ltd-sti-151349-3173

[11] https://www.directindustry.com/prod/sarem/product-242485-2537760.html

[12] https://new.abb.com/docs/librariesprovider87/case-documentation/1405_sarem_makina_case_article_reva.pdf?sfvrsn=2

[13] https://www.sarem.com.tr/en/pipe-production-lines/

[14] https://fa.machinery-hitech.com/blog/top-10-pipe-extrusion-machine-manufacturers-254742.html

[15] https://www.sarem.com.tr/en/product-listing/

[16] https://www.sarem.com.tr/en/extruders/

[17] https://www.directindustry.com/prod/sarem/product-242485-2537369.html

[18] https://www.directindustry.com/prod/sarem-242485.html

[19] https://www.plantautomation-technology.com/products/sarem-machinery/extruders

[20] https://ms.machinery-hitech.com/blog/detail-194451.html

[21] https://www.sarem.com.tr/en/sarem-machinery-plastic-pipe-extrusion-lines-machinery/

[22] https://www.directindustry.com/prod/sarem/product-242485-2537316.html

[23] https://www.instagram.com/saremmakina/p/CXvMiJ7tnXV/

[24] https://new.abb.com/drives/highlights-and-references/article-sarem-makina