Content Menu

● The Role of Extrusion Machinery in Plastics Manufacturing

● Overview of Plastics Extrusion Machinery LLC Olympia WA

● Main Types of Extrusion Machinery Offered

>> Pipe and Profile Pullers

>> Belling Machines

>> Hydrostatic Testing Machines

>> Chamfering Machines

>> Vacuum and Cooling Tanks

>> Precision Saws

>> Lift & Rotators, Pipe Stacking Units, and Unibundler Machines

>> Aftercoolers

>> Spare Parts and Engineering Support

● Types of Extrusion Techniques and Machines

>> Single Screw Extruders

>> Twin Screw Extruders

>> Ram Extruders

>> Multilayer and Co-Extrusion Systems

● Innovative Downstream Solutions: The PEM Advantage

● Applications of Plastics Extrusion Machinery LLC Equipment

● Engineering Support and Customization

● Comparison of Key Extrusion Machinery Types

● Commitment to Quality and ROI

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What makes Plastics Extrusion Machinery LLC Olympia WA unique in the extrusion machinery market?

>> 2. Which industries benefit most from Plastics Extrusion Machinery LLC's equipment?

>> 3. Can Plastics Extrusion Machinery LLC Olympia WA customize equipment for specific production needs?

>> 4. What types of plastics can be processed with their machinery?

>> 5. How does the company support customers after equipment installation?

● Citations:

Plastics Extrusion Machinery LLC, based in Olympia, WA, stands at the forefront of the plastics extrusion industry, offering a comprehensive range of innovative machinery and downstream solutions tailored to the needs of modern PVC and profile extrusion plants. With a reputation for engineering excellence, long-term reliability, and a focus on maximizing return on investment, Plastics Extrusion Machinery LLC Olympia WA has become a trusted partner for manufacturers across the United States and beyond. This article provides an in-depth exploration of the types of extrusion machinery the company specializes in, the technologies behind these systems, their applications, and the unique advantages they deliver to the plastics industry.

The Role of Extrusion Machinery in Plastics Manufacturing

Extrusion is a fundamental process in plastics manufacturing, enabling the continuous production of pipes, profiles, sheets, and a wide variety of custom products. The process involves melting raw plastic materials and forcing them through a die to create objects of fixed cross-sectional profiles. The efficiency, quality, and versatility of the final products depend heavily on the sophistication and reliability of the extrusion machinery used[2][4].

Overview of Plastics Extrusion Machinery LLC Olympia WA

Plastics Extrusion Machinery LLC Olympia WA has established itself as a leader in downstream extrusion equipment, particularly for the PVC pipe and profile sectors. The company's product portfolio reflects a commitment to innovation, durability, and customer-focused engineering support. Their machinery is designed to optimize production efficiency, product quality, and operational longevity, making them a preferred choice for extrusion plants aiming for excellence[1].

Main Types of Extrusion Machinery Offered

Pipe and Profile Pullers

Pipe and profile pullers are essential for maintaining consistent tension and speed as extruded products exit the die. Plastics Extrusion Machinery LLC Olympia WA offers advanced pullers designed for both pipes and complex profiles, ensuring smooth, distortion-free handling and precise sizing throughout the extrusion line[1].

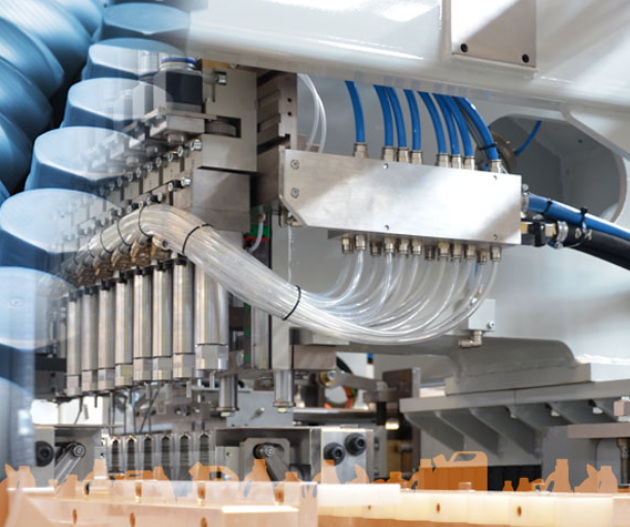

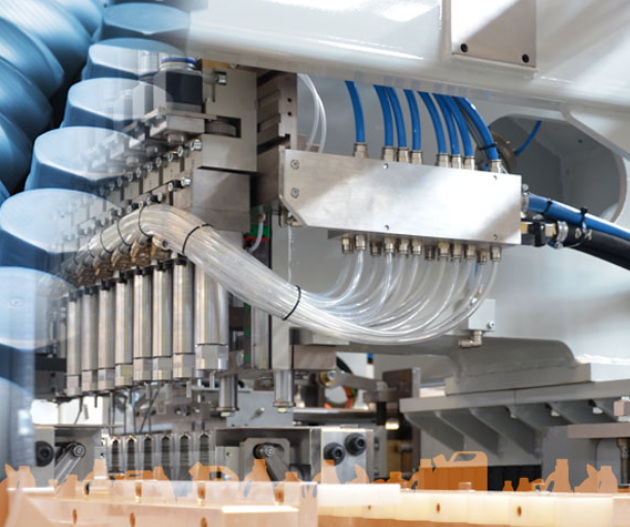

Belling Machines

Belling machines are used to form socket ends on pipes, a critical step for applications requiring pipe joining and assembly. The company provides both single-head and multi-head belling machines, capable of handling various pipe diameters and wall thicknesses. These machines are engineered for speed, repeatability, and minimal downtime, supporting high-volume production environments[1].

Hydrostatic Testing Machines

Hydrostatic testing is vital for ensuring the structural integrity and leak-proof performance of extruded pipes. Plastics Extrusion Machinery LLC Olympia WA supplies hydrostatic testing machines that automate the process, delivering accurate, repeatable results while streamlining quality assurance protocols[1].

Chamfering Machines

Chamfering machines are used to bevel the ends of pipes, facilitating easier assembly and reducing the risk of damage during installation. The company offers both single-head and multi-head chamfering machines for internal and external chamfers, adaptable to a wide range of pipe sizes and materials[1].

Vacuum and Cooling Tanks

Vacuum tanks play a crucial role in shaping and sizing extruded pipes and profiles by applying negative pressure immediately after the die. Cooling tanks then rapidly lower the temperature of the extrudate, stabilizing its dimensions and improving surface quality. Plastics Extrusion Machinery LLC Olympia WA provides vacuum and cooling tanks in various sizes and configurations, tailored to specific product requirements[1].

Precision Saws

Cutting extruded products to precise lengths is essential for downstream processing and product uniformity. The company's precision saws are engineered for clean, accurate cuts with minimal material waste, suitable for both high-speed and heavy-duty applications[1].

Lift & Rotators, Pipe Stacking Units, and Unibundler Machines

For efficient material handling and automation, Plastics Extrusion Machinery LLC Olympia WA offers lift & rotators, pipe stacking units, and unibundler machines. These systems streamline the movement, bundling, and storage of finished products, reducing labor costs and improving plant safety[1].

Aftercoolers

Aftercoolers provide efficient secondary cooling for belled pipes, further enhancing production throughput and product quality by ensuring pipes are ready for immediate handling or further processing[1].

Spare Parts and Engineering Support

The company manufactures many spare parts in-house, ensuring quick fulfillment and easy installation. Their engineering support spans the entire end-to-end process, from initial consultation and machine selection to installation, training, and ongoing maintenance[1].

Types of Extrusion Techniques and Machines

While Plastics Extrusion Machinery LLC Olympia WA is renowned for its downstream equipment, understanding the broader context of extrusion machinery is essential. The main types of extrusion machines used in the plastics industry include:

Single Screw Extruders

Single screw extruders are the most common type, featuring a rotating screw within a heated barrel that melts and conveys plastic material toward a die. These machines are versatile, cost-effective, and ideal for standard extrusion applications such as pipes, sheets, and simple profiles[2][4].

Twin Screw Extruders

Twin screw extruders utilize two intermeshing or parallel screws, offering superior mixing, homogenization, and control over the extrusion process. They are preferred for complex formulations, filled plastics, and applications requiring precise material blending and thermal management[2][4].

Ram Extruders

Ram extruders use a piston or ram to force plastic material through a die, suitable for high-viscosity materials or products requiring a high degree of compaction. They are less common but valuable for specific applications such as thick-walled pipes or highly filled compounds[2][4].

Multilayer and Co-Extrusion Systems

These machines combine multiple extruders to produce products with layered structures, each layer offering distinct properties. Multilayer extrusion is widely used in packaging films, co-extruded pipes, and other advanced applications[4][5].

Innovative Downstream Solutions: The PEM Advantage

Plastics Extrusion Machinery LLC Olympia WA distinguishes itself through its focus on downstream solutions—machinery that processes, finishes, and handles extruded products after they exit the die. This specialization brings several advantages:

- Enhanced Product Quality: Downstream equipment such as vacuum tanks, cooling tanks, and precision saws ensure that extruded products meet tight dimensional tolerances and surface quality standards.

- Increased Efficiency: Automated pullers, stackers, and belling machines streamline production, reduce labor requirements, and minimize cycle times.

- Long-Term Reliability: The company's equipment is engineered for durability, with robust construction and components designed for extended service life.

- Comprehensive Support: From spare parts to engineering assistance, Plastics Extrusion Machinery LLC Olympia WA supports customers throughout the equipment lifecycle, maximizing uptime and return on investment[1].

Applications of Plastics Extrusion Machinery LLC Equipment

The machinery produced by Plastics Extrusion Machinery LLC Olympia WA serves a diverse range of industries and applications, including:

- PVC Pipe Manufacturing: For water supply, drainage, electrical conduits, and irrigation systems.

- Profile Extrusion: Window frames, door profiles, and custom shapes for construction and automotive industries.

- Sheet and Film Production: Used in packaging, signage, and industrial applications.

- Specialty Products: Co-extruded pipes, multilayer films, and custom-engineered profiles.

Engineering Support and Customization

A hallmark of Plastics Extrusion Machinery LLC Olympia WA is its commitment to engineering support and customization. The company works closely with clients to understand their specific production requirements, offering tailored solutions that optimize performance, throughput, and cost-effectiveness. Whether upgrading an existing line or designing a new extrusion plant, customers benefit from expert guidance and innovative problem-solving[1].

Comparison of Key Extrusion Machinery Types

| Machine Type | Principle/Function | Typical Applications | Advantages |

| Pipe and Profile Pullers | Maintains tension and speed post-die | Pipes, profiles | Consistent sizing, smooth handling |

| Belling Machines | Forms socket ends on pipes | Pipe joining/assembly | High-speed, repeatable, reliable |

| Hydrostatic Testing Machines | Tests pipe strength and leak resistance | Quality assurance for pipes | Automated, accurate, efficient |

| Chamfering Machines | Bevels pipe ends | Pipe assembly, installation | Versatile, adaptable, improves assembly |

| Vacuum/Cooling Tanks | Shapes and cools extrudate | Pipes, profiles, sheets | Precise sizing, improved surface quality |

| Precision Saws | Cuts extrudate to length | All extruded products | Clean, accurate cuts, minimal waste |

| Lift & Rotators/Stackers | Material handling and automation | Finished pipes, profiles | Labor savings, improved safety |

| Single Screw Extruder | Melts/conveys plastic with one screw | General extrusion (pipes, sheets, profiles) | Simple, cost-effective, versatile |

| Twin Screw Extruder | Uses two screws for enhanced mixing | Complex/filled plastics, masterbatches | Superior mixing, precise control |

| Ram Extruder | Uses piston/ram for compaction | High-viscosity/filled materials | Handles difficult materials, high compaction |

| Multilayer Extruder | Combines multiple plastics into layered products | Packaging films, co-extruded pipes | Enhanced product properties, versatility |

Commitment to Quality and ROI

Plastics Extrusion Machinery LLC Olympia WA places a strong emphasis on manufacturing equipment that delivers long-term value. Their machinery is built to withstand demanding production environments, with features designed to maximize productivity, minimize maintenance, and ensure consistent product quality. This focus on quality and return on investment has earned the company a loyal customer base and a prominent position in the extrusion machinery market[1].

Conclusion

Plastics Extrusion Machinery LLC Olympia WA has carved out a leading role in the plastics extrusion industry through its commitment to innovation, quality, and customer-focused engineering. Specializing in downstream extrusion machinery, the company offers a broad portfolio of solutions that streamline production, enhance product quality, and deliver long-term value. From pipe and profile pullers to belling machines, hydrostatic testing systems, and advanced material handling equipment, their machinery is trusted by manufacturers nationwide. With a focus on customization, engineering support, and robust construction, Plastics Extrusion Machinery LLC Olympia WA continues to set the standard for excellence in extrusion technology.

Frequently Asked Questions (FAQ)

1. What makes Plastics Extrusion Machinery LLC Olympia WA unique in the extrusion machinery market?

Plastics Extrusion Machinery LLC Olympia WA specializes in innovative downstream solutions that enhance the efficiency, quality, and automation of extrusion lines. Their equipment is engineered for durability, ease of maintenance, and maximum ROI, backed by comprehensive engineering support throughout the equipment lifecycle[1].

2. Which industries benefit most from Plastics Extrusion Machinery LLC's equipment?

Their machinery is widely used in the PVC pipe and profile industries, construction, automotive, packaging, and any sector requiring high-quality extruded plastic products. The versatility and customization options make their equipment suitable for both standard and specialized applications[1].

3. Can Plastics Extrusion Machinery LLC Olympia WA customize equipment for specific production needs?

Yes, the company offers tailored solutions based on client requirements, including custom sizing, configurations, and integration with existing production lines. Their engineering team collaborates closely with customers to deliver optimized, turnkey solutions[1].

4. What types of plastics can be processed with their machinery?

While the company's equipment is particularly prevalent in PVC extrusion, it is also compatible with a wide range of thermoplastics, including polyethylene, polypropylene, and specialty compounds, depending on the specific machine and application[4][5].

5. How does the company support customers after equipment installation?

Plastics Extrusion Machinery LLC Olympia WA provides ongoing engineering support, spare parts manufactured in-house for quick delivery, and assistance with maintenance, troubleshooting, and upgrades to ensure maximum uptime and productivity[1].

Citations:

[1] https://www.pemusa.com/products

[2] http://www.industrialextrusionmachinery.com/types_of_plastic_extruders.html

[3] https://www.milacron.com/product-types/extrusion-machines/

[4] https://www.cnchaoxu.com/news-center/what-are-the-different-types-of-plastic-extrusion-machines

[5] https://plasticextrusiontech.net

[6] https://www.pemusa.com

[7] https://ensun.io/search/plastic-extruding-machinery/united-states

[8] https://www.thomasnet.com/suppliers/usa/plastics-extrusion-equipment-96202767