Content Menu

● Introduction to Extrusion Equipment

>> Types of Extrusion Equipment

● Applications of Extrusion Equipment

>> Chemical Industry Applications

>> Food and Pharmaceutical Industries

● Factors to Consider When Buying Extrusion Equipment

>> Machine Type and Application

>> Capacity and Output

>> Budget and Cost

>> Supplier Reputation and Support

● Where to Buy Extrusion Equipment

● Future Trends in Extrusion Technology

● Maintenance and Upkeep of Extrusion Equipment

● Cost Considerations for Starting an Extrusion Plant

● Conclusion

● FAQ

>> 1. What are the main types of extrusion equipment available for sale?

>> 2. How do I choose between a single screw and twin screw extruder?

>> 3. What factors affect the cost of extrusion equipment?

>> 4. Where can I find used extrusion equipment for sale?

>> 5. What are the benefits of buying refurbished extrusion equipment?

● Citations:

The extrusion equipment market offers a wide range of machinery designed to cater to various industrial needs, from simple plastic films to complex composite materials. In this article, we will explore the different types of extrusion equipment available for sale, their applications, and the factors to consider when purchasing such machinery.

Introduction to Extrusion Equipment

Extrusion is a process used to create objects of a fixed cross-sectional profile. It involves forcing raw materials through a die to produce the desired shape. Extrusion equipment is crucial in industries such as plastics, food, and pharmaceuticals, where it is used to manufacture products like pipes, sheets, films, and even snack foods.

Types of Extrusion Equipment

1. Single Screw Extruders: These are the most common type of extruder and are used for simple extrusion processes. They are cost-effective and suitable for producing products like plastic pipes and films. Single screw extruders are ideal for industries where the material properties do not require complex mixing or compounding.

Example of a Single Screw Extruder:

- Screw Diameter: 60 mm

- Output: 60 kg/h

- Price Range: €12,000 to €55,000

2. Twin Screw Extruders: These are more versatile and are used for compounding and mixing different materials. They are ideal for producing complex plastic products and are commonly used in the automotive and packaging industries. Twin screw extruders offer better mixing capabilities compared to single screw models, making them suitable for applications requiring precise material properties.

Example of a Twin Screw Extruder:

- Screw Diameter: 65 mm

- Output: 250 kg/h

- Price Range: €24,000 to €97,000

3. Blown Film Extruders: These are specialized for producing plastic films used in packaging. They are equipped with advanced features like edge position control and corona treatment for printing. Blown film extruders are essential in the packaging industry for creating thin, durable films.

Example of a Blown Film Extruder:

- Max Film Width: 2500 mm

- Output: 270 kg/h

- Price Range: Customized based on specifications

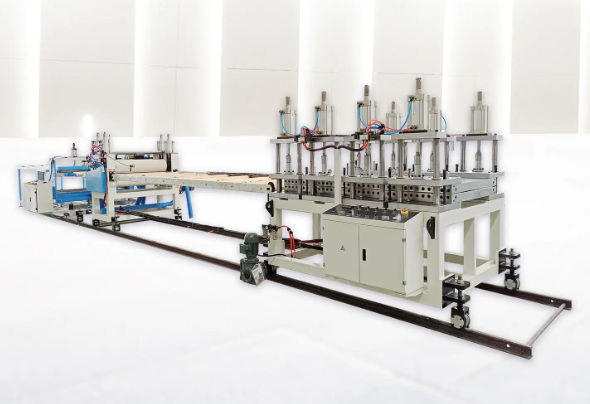

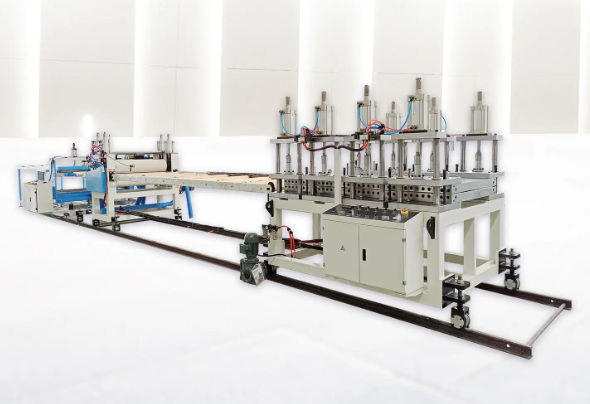

4. Pipe Extruders: Designed specifically for producing PVC pipes and other types of tubing. They are available in various sizes and configurations. Pipe extruders are crucial in the construction industry for producing pipes used in plumbing and infrastructure projects.

Example of a Pipe Extruder:

- Pipe Diameter: Up to 160 mm

- Output: Customizable based on material and size

- Price Range: Varies with specifications

Applications of Extrusion Equipment

Extrusion equipment is used across various industries due to its versatility and efficiency.

Chemical Industry Applications

In the chemical industry, extrusion is used to produce a wide range of products, including:

- Plastic Manufacturing: Extrusion is essential for producing plastic pipes, sheets, films, and profiles. These materials are used in industries such as electronics, automotive, packaging, and construction[2].

- Rubber and Elastomer Production: Extrusion is used to process rubber compounds for applications like tires, gaskets, and seals. It ensures consistent product quality and accurate dimensions[2].

- Chemical Coatings and Film Extrusion: Extrusion aids in applying consistent coatings to materials like plastic films or metal wires, enhancing their properties[2].

- Composite Materials Manufacturing: Extrusion is used to produce composite materials by mixing different materials to improve strength and durability[2].

Food and Pharmaceutical Industries

Extrusion is also used in the food and pharmaceutical industries for producing products like snack foods and pharmaceutical pellets. The extrusion process allows for precise control over the size and shape of these products, making it ideal for applications requiring uniformity[2].

Factors to Consider When Buying Extrusion Equipment

When purchasing extrusion equipment for sale, several factors must be considered to ensure the right machine is selected for your specific needs.

Machine Type and Application

- Single Screw vs. Twin Screw: Single screw extruders are suitable for simple extrusions, while twin screw extruders are better for complex mixing and compounding processes.

- Material Compatibility: Ensure the machine can handle the type of plastic or material you plan to use.

Capacity and Output

- Production Volume: Choose a machine that can meet your desired production volume in terms of kilograms per hour.

- Screw Diameter and L/D Ratio: These parameters affect the machine's efficiency and output quality.

Budget and Cost

- Initial Purchase Price: Single screw extruders are generally less expensive than twin screw models.

- Operating Costs: Consider energy efficiency and maintenance costs over the machine's lifespan.

Supplier Reputation and Support

- Brand Reliability: Opt for reputable manufacturers known for quality and reliability.

- After-Sales Service: Ensure the supplier offers good technical support and spare parts availability.

Where to Buy Extrusion Equipment

Extrusion equipment for sale can be found through various channels:

1. New Equipment Manufacturers: Companies like Davis-Standard and Battenfeld-Cincinnati offer brand-new machines with warranties.

2. Used Equipment Dealers: Platforms like Exapro and Machineseeker provide a wide range of used extruders at competitive prices.

3. Refurbished Equipment: Some dealers offer refurbished machines that have been inspected and upgraded to near-new condition.

Future Trends in Extrusion Technology

The future of extrusion technology is promising, with advancements in automation, AI, and 3D printing. These technologies enhance precision, efficiency, and customization capabilities.

- Automation and AI: Advances in automation and AI lead to more precise control of extrusion processes, optimizing production and reducing waste[1].

- 3D Printing Integration: Combining 3D printing with extrusion allows for complex geometries and customized products, expanding manufacturing possibilities[1][5].

Maintenance and Upkeep of Extrusion Equipment

Regular maintenance is crucial for ensuring the longevity and performance of extrusion equipment. This includes:

- Scheduled Inspections: Regularly inspect critical components like the hydraulic system and cooling systems for signs of wear or damage[3].

- Lubrication: Ensure all moving parts are properly lubricated to reduce friction and wear[3].

- Cleanliness: Maintain a clean workspace to prevent blockages and damage from debris[3].

Cost Considerations for Starting an Extrusion Plant

Starting an extrusion plant involves several cost considerations:

- Machinery Costs: Investing in used or refurbished equipment can significantly reduce initial costs[4].

- Facility Costs: Leasing a facility instead of purchasing can lower initial expenses[4].

- Raw Materials: Building strong relationships with suppliers can lead to bulk purchasing discounts[4].

Conclusion

Choosing the right extrusion equipment for sale involves careful consideration of several factors, including machine type, capacity, budget, and supplier reputation. Whether you are looking for single screw, twin screw, or specialized extruders like blown film or pipe extruders, there are numerous options available in the market. By understanding your production needs and selecting the appropriate machinery, you can optimize your manufacturing process and achieve higher productivity and quality.

FAQ

1. What are the main types of extrusion equipment available for sale?

- The main types include single screw extruders, twin screw extruders, blown film extruders, and pipe extruders.

2. How do I choose between a single screw and twin screw extruder?

- Single screw extruders are suitable for simple extrusions, while twin screw extruders are better for complex mixing and compounding processes.

3. What factors affect the cost of extrusion equipment?

- The cost is influenced by machine type, capacity, material handling capabilities, and supplier reputation.

4. Where can I find used extrusion equipment for sale?

- Used extrusion equipment can be found through dealers like Exapro and Machineseeker.

5. What are the benefits of buying refurbished extrusion equipment?

- Refurbished equipment offers a cost-effective option with near-new performance and reliability.

Citations:

[1] https://kama-packaging.com/en/the-future-of-extrusion-technology-new-materials-and-technologies/

[2] https://kriimpasindia.com/extrusion-applications-in-chemical-industries/

[3] https://satimaco.wixsite.com/satimaco/post/aluminum-extrusion-machine-maintenance-tips-for-peak-performance

[4] https://businessplan-templates.com/blogs/startup-costs/pvc-extrusion-plant

[5] https://www.alcircle.com/news/tech-trends-driving-the-aluminium-extrusion-industry-111131

[6] https://yamunaind.com/innovation-spotlight-recent-advancements-in-aluminium-extrusion-technology/

[7] https://jieyatwinscrew.com/blog/exploring-the-world-of-extrusion-machines-understanding-the-basics-and-benefits/

[8] https://davis-standard.com/custom_blog/10-tips-to-keep-your-extruder-pumping/

[9] https://www.plasticstoday.com/plastics-processing/reducing-energy-costs-focus-on-extrusion

[10] https://profileprecisionextrusions.com/the-evolution-of-aluminum-extrusions-emerging-trends-and-technologies/

[11] https://www.wevolver.com/article/extruding-plastic

[12] https://paulmurphyplastics.com/industry-news-blog/extrusion-process-working-types-application-advantages-and-disadvantages/

[13] https://www.grahamengineering.com/about/ge-connect/proper-extruder-maintenance-a-key-to-success/

[14] https://rollepaal.com/knowledge/optimization-of-raw-material-selection-for-cost-effectiveness-in-pipe-extrusion/

[15] https://nationalindustries.world/2025/01/02/the-future-of-aluminum-how-extrusion-technology-is-transforming-industries/

[16] https://www.ptonline.com/articles/get-ready-to-be-blown-away-with-new-extrusion-technology

[17] https://cfaminternational.com/top-commercial-applications-of-extrusion-technology/

[18] https://www.jwellmachine.com/winter-maintenance-tips-for-plastic-extrusion-equipment/

[19] https://apenergy.com/blogs/the-top-energy-efficiency-tips-for-reducing-plastic-extrusion-energy-costs/

[20] https://hunterplastics.com/trends-in-plastic-extrusion-technology