Content Menu

● Introduction

● Understanding Channel Aluminum Extrusions

>> U-Channels

>> C-Channels

>> Structural Channels

● Benefits of Using Channel Aluminum Extrusions

>> Durability and Strength

>> Lightweight Nature

>> Versatility in Design and Application

● Choosing the Right Aluminum Channel

>> Size and Shape

>> Material Properties

>> Customization Options

● Applications of Channel Aluminum Extrusions

>> Construction

>> Industrial Applications

>> Creative Uses in Art and Design

● Finding Reliable Aluminum Channel Suppliers

>> Quality and Service

>> Customization Services

>> Support and Expertise

● Conclusion

● Related Questions

>> 1. What are the main differences between U-channels and C-channels?

>> 2. Can aluminum channels be customized for specific projects?

>> 3. What are the advantages of using aluminum channels in construction?

>> 4. How do I choose the right aluminum channel for my project?

>> 5. Where can I find reliable suppliers for aluminum channels?

Introduction

Aluminum channels are essential components in various industries, known for their strength, lightweight nature, and versatility. Among the different types of aluminum profiles, channel aluminum extrusion profiles stand out due to their unique shapes and applications. This article explores the various types of aluminum channels available for custom fabrication, their benefits, and how to choose the right one for your project.

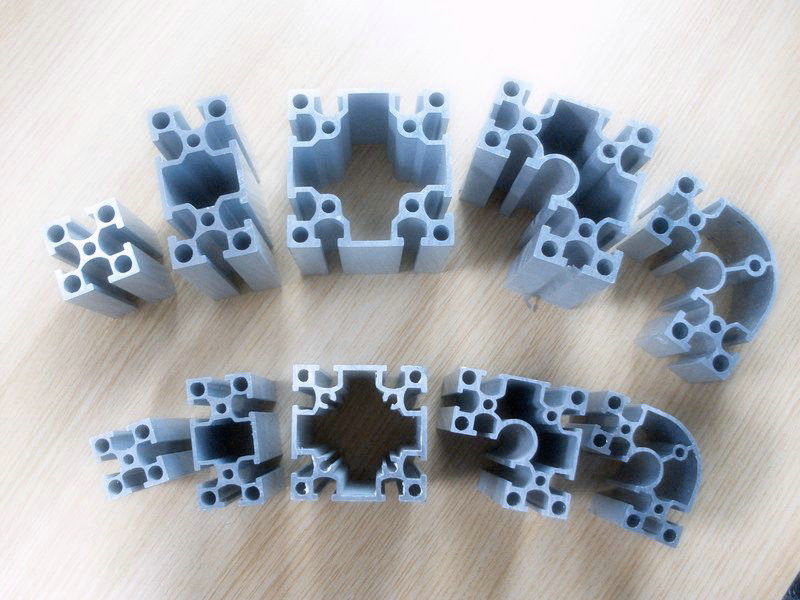

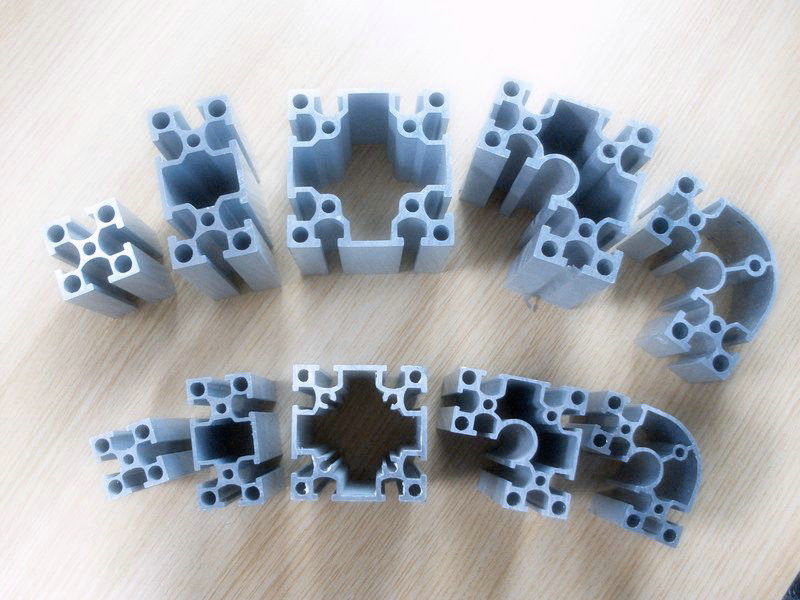

Understanding Channel Aluminum Extrusions

Channel aluminum extrusions are formed by pushing aluminum through a die to create a specific cross-sectional shape. The most common types of channel profiles include U-channels, C-channels, and structural channels. Each type serves different purposes and is used in various applications, from construction to manufacturing.

U-Channels

U-channels are characterized by their U-shaped cross-section. They are widely used in construction and manufacturing due to their strength and stability. U-channels can be used as supports, frames, or guides in various applications. Their design allows for easy integration with other components, making them a popular choice for custom fabrication.

C-Channels

C-channels, similar to U-channels, have a C-shaped cross-section. They are often used in structural applications where strength and rigidity are required. C-channels are commonly found in building frameworks, machinery, and equipment. Their design allows for easy attachment to other materials, making them ideal for custom fabrication.

Structural Channels

Structural channels are designed for heavy-duty applications. They have a more robust profile and are used in construction, bridges, and other infrastructure projects. Structural channels provide excellent load-bearing capabilities and are often used in combination with other materials to create strong frameworks.

Benefits of Using Channel Aluminum Extrusions

Channel aluminum extrusions offer numerous advantages that make them a preferred choice in various industries.

Durability and Strength

Aluminum is known for its strength-to-weight ratio, making it an ideal material for structural applications. Channel aluminum extrusions are resistant to corrosion, ensuring longevity even in harsh environments. This durability makes them suitable for both indoor and outdoor applications.

Lightweight Nature

One of the most significant benefits of aluminum channels is their lightweight nature. This characteristic allows for easy handling and installation, reducing labor costs and time. Lightweight materials are particularly advantageous in industries where weight restrictions are critical, such as aerospace and automotive.

Versatility in Design and Application

Channel aluminum extrusions can be customized to meet specific project requirements. They can be cut, drilled, and shaped to fit various applications, making them highly versatile. This adaptability allows engineers and designers to create innovative solutions tailored to their needs.

Choosing the Right Aluminum Channel

When selecting the right aluminum channel for your project, several factors should be considered.

Size and Shape

The size and shape of the aluminum channel are crucial for its intended application. U-channels and C-channels come in various dimensions, and choosing the right one depends on the load requirements and space constraints of your project.

Material Properties

Different aluminum alloys offer varying properties, such as strength, corrosion resistance, and weldability. Understanding the specific requirements of your project will help you select the appropriate alloy for your aluminum channel.

Customization Options

Many manufacturers offer customization options for aluminum channels. This can include specific lengths, finishes, and additional features such as holes for easy attachment. Customization allows for a more tailored solution that meets the unique needs of your project.

Applications of Channel Aluminum Extrusions

Channel aluminum extrusions are used in a wide range of applications across various industries.

Construction

In the construction industry, channel aluminum extrusions are used for framing, supports, and architectural features. Their strength and lightweight nature make them ideal for creating durable structures that can withstand various environmental conditions.

Industrial Applications

Aluminum channels are commonly used in industrial settings for machinery, equipment, and fixtures. Their ability to support heavy loads while remaining lightweight makes them a popular choice for manufacturing processes.

Creative Uses in Art and Design

Beyond traditional applications, channel aluminum extrusions are also used in creative projects, such as art installations and custom furniture. Their sleek appearance and versatility allow designers to create unique pieces that stand out.

Finding Reliable Aluminum Channel Suppliers

When looking for aluminum channel suppliers, it is essential to consider several factors to ensure you receive high-quality products and services.

Quality and Service

Choose suppliers known for their quality products and excellent customer service. Reading reviews and testimonials can provide insight into the supplier's reputation.

Customization Services

Look for suppliers that offer customization options for aluminum channels. This flexibility allows you to create tailored solutions that meet your specific project requirements.

Support and Expertise

A reliable supplier should provide support and expertise throughout the purchasing process. This includes assistance with selecting the right products and guidance on fabrication techniques.

Conclusion

Channel aluminum extrusion profiles are versatile and durable components used in various industries. Understanding the different types of aluminum channels available for custom fabrication can help you make informed decisions for your projects. Whether you need U-channels, C-channels, or structural channels, the benefits of using aluminum are clear. Its lightweight nature, strength, and adaptability make it an ideal choice for construction, industrial applications, and creative projects.

Related Questions

1. What are the main differences between U-channels and C-channels?

U-channels have a U-shaped cross-section, while C-channels have a C-shaped profile. U-channels are often used for supports and guides, whereas C-channels are typically used in structural applications.

2. Can aluminum channels be customized for specific projects?

Yes, many manufacturers offer customization options for aluminum channels, including specific lengths, finishes, and additional features.

3. What are the advantages of using aluminum channels in construction?

Aluminum channels are lightweight, durable, and resistant to corrosion, making them ideal for construction applications where strength and longevity are essential.

4. How do I choose the right aluminum channel for my project?

Consider factors such as size, shape, material properties, and customization options when selecting the right aluminum channel for your project.

5. Where can I find reliable suppliers for aluminum channels?

Look for suppliers with a good reputation for quality products and customer service. Reading reviews and seeking recommendations can help you find reliable sources.