Content Menu

● Understanding Aluminum Extrusion

>> Benefits of Using 2x2 Aluminum Extrusion

● Essential Tools for Working with 2x2 Aluminum Extrusion

>> 1. Cutting Tools

>> 2. Drilling Tools

>> 3. Fastening Tools

>> 4. Measuring and Marking Tools

>> 5. Finishing Tools

>> 6. Safety Equipment

● Techniques for Working with 2x2 Aluminum Extrusion

>> Cutting Techniques

>> Drilling Techniques

>> Assembly Techniques

● Common Applications of 2x2 Aluminum Extrusion

● Tips for Successful Projects

● Conclusion

● Frequently Asked Questions

>> 1. What is the best way to cut 2x2 aluminum extrusion?

>> 2. Can I drill holes in aluminum extrusion?

>> 3. What type of fasteners should I use with aluminum extrusion?

>> 4. How do I ensure accurate measurements when working with aluminum extrusion?

>> 5. What safety equipment should I wear when working with aluminum extrusion?

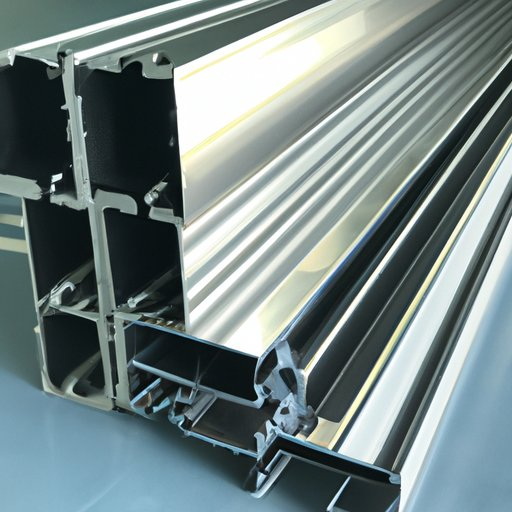

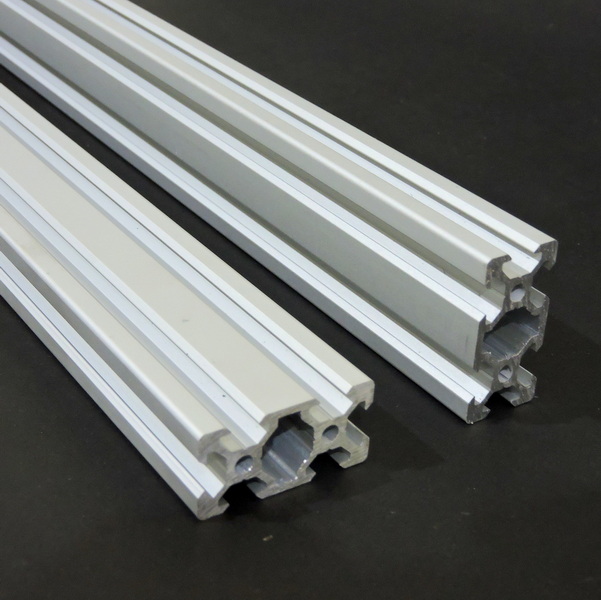

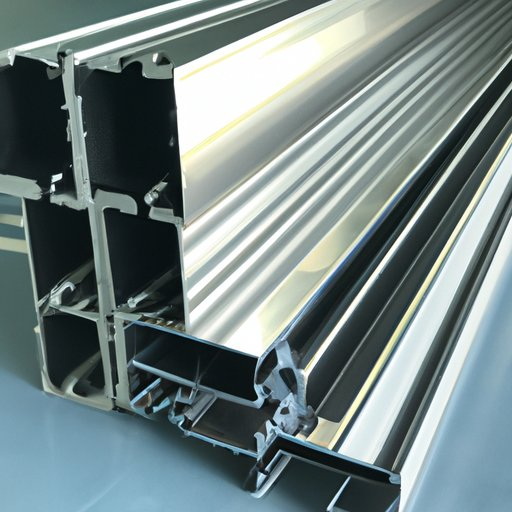

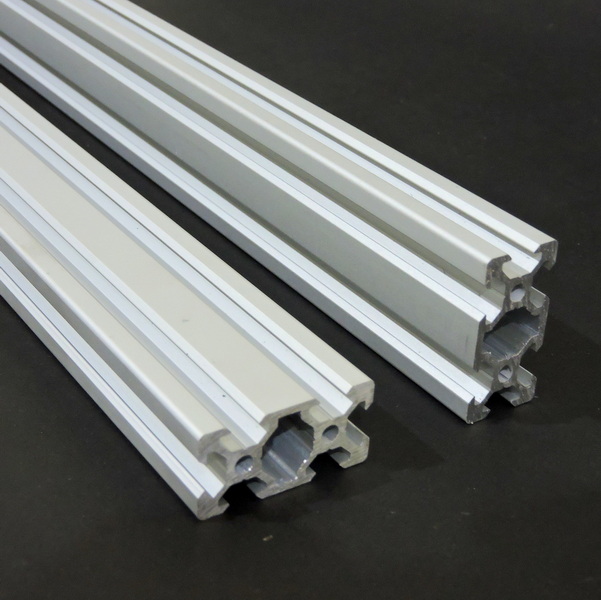

Aluminum extrusion is a versatile and widely used manufacturing process that allows for the creation of complex shapes and profiles. Among the various sizes available, the 2x2 aluminum extrusion is particularly popular due to its strength, lightweight nature, and ease of use. Whether you are a DIY enthusiast, a professional fabricator, or an engineer, understanding the tools required to work with 2x2 aluminum extrusion is essential for achieving high-quality results. In this article, we will explore the necessary tools, techniques, and tips for working with 2x2 aluminum extrusion effectively.

Understanding Aluminum Extrusion

Before diving into the tools, it's important to understand what aluminum extrusion is. The process involves forcing heated aluminum through a die to create a specific cross-sectional shape. This method allows for the production of long lengths of aluminum profiles that can be cut to size for various applications, including structural frames, enclosures, and custom projects.

Benefits of Using 2x2 Aluminum Extrusion

1. Strength and Durability: Aluminum is known for its strength-to-weight ratio, making it ideal for structural applications.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps resist corrosion.

3. Lightweight: Compared to steel, aluminum is significantly lighter, making it easier to handle and transport.

4. Versatility: The 2x2 profile can be used in a variety of applications, from furniture to industrial machinery.

5. Ease of Assembly: With the right tools, 2x2 aluminum extrusions can be easily cut, drilled, and assembled.

Essential Tools for Working with 2x2 Aluminum Extrusion

1. Cutting Tools

Cutting aluminum extrusion accurately is crucial for ensuring that your pieces fit together properly. Here are some common cutting tools used for this purpose:

- Miter Saw: A miter saw equipped with a non-ferrous metal cutting blade is one of the best tools for cutting aluminum extrusion. It provides clean, precise cuts at various angles.

- Band Saw: A band saw can also be used for cutting aluminum, especially for larger pieces. It allows for more intricate cuts and is ideal for thicker extrusions.

- Hack Saw: For smaller projects or when precision is less critical, a hand-held hack saw can be used. However, it requires more effort and may not provide as clean a cut.

2. Drilling Tools

Drilling holes in aluminum extrusion is often necessary for assembly and fastening. The following tools are essential:

- Drill Press: A drill press provides stability and precision when drilling holes in aluminum. It allows for consistent depth and alignment.

- Cordless Drill: For more portable applications, a cordless drill with the appropriate drill bits can be used. Make sure to use bits designed for metal to avoid dulling.

3. Fastening Tools

Once your aluminum pieces are cut and drilled, you will need to assemble them. Here are some fastening tools to consider:

- Screws and Bolts: Use screws or bolts specifically designed for aluminum. These fasteners often have a finer thread to grip the softer material better.

- T-Slot Nuts: If you are using T-slot aluminum extrusions, T-slot nuts are essential for creating a secure connection without the need for additional hardware.

- Rivet Gun: For permanent connections, a rivet gun can be used to secure pieces together. This is particularly useful in applications where disassembly is not required.

4. Measuring and Marking Tools

Accurate measurements are critical in any fabrication project. The following tools will help ensure precision:

- Tape Measure: A standard tape measure is essential for measuring lengths and distances accurately.

- Square: A framing square or combination square helps ensure that your cuts are straight and your angles are correct.

- Marking Tools: Use a fine-tip marker or scribe to mark your cut lines clearly on the aluminum.

5. Finishing Tools

After cutting and assembling your aluminum extrusion, you may want to finish the edges for a smoother appearance:

- File: A metal file can be used to smooth out rough edges after cutting.

- Deburring Tool: This tool helps remove sharp edges and burrs from drilled holes, making the finished product safer to handle.

6. Safety Equipment

Working with aluminum extrusion involves cutting and drilling, which can pose safety risks. Always wear appropriate safety gear:

- Safety Glasses: Protect your eyes from metal shavings and debris.

- Gloves: Use cut-resistant gloves to protect your hands while handling sharp edges.

- Ear Protection: If using power tools, ear protection is advisable to prevent hearing damage.

Techniques for Working with 2x2 Aluminum Extrusion

Cutting Techniques

1. Secure the Material: Always secure your aluminum extrusion in a vise or clamp before cutting to prevent movement.

2. Use the Right Blade: Ensure that your saw blade is designed for cutting aluminum to achieve the best results.

3. Cut Slowly: Take your time when cutting to avoid overheating the blade and to ensure a clean cut.

Drilling Techniques

1. Use a Center Punch: Mark your drilling points with a center punch to prevent the drill bit from wandering.

2. Lubricate the Bit: Using cutting oil can help reduce friction and prolong the life of your drill bits.

3. Drill at a Steady Speed: Maintain a consistent speed while drilling to avoid damaging the material.

Assembly Techniques

1. Pre-assemble: Before final assembly, lay out all pieces to ensure they fit together as planned.

2. Use a Level: When assembling larger structures, use a level to ensure everything is aligned correctly.

3. Tighten Fasteners Securely: Ensure that all screws and bolts are tightened properly to maintain structural integrity.

Common Applications of 2x2 Aluminum Extrusion

2x2 aluminum extrusions are used in a variety of applications, including:

- Furniture: Many modern furniture designs utilize aluminum extrusion for frames and supports due to its strength and aesthetic appeal.

- Industrial Racks: Aluminum extrusions are commonly used in warehouses and factories for creating shelving and storage solutions.

- Automotive: In the automotive industry, aluminum extrusions are used for lightweight structural components.

- DIY Projects: Hobbyists and DIY enthusiasts often use aluminum extrusions for custom projects, such as robotics and home improvement.

Tips for Successful Projects

1. Plan Your Design: Before starting any project, take the time to plan your design thoroughly. Sketch out your ideas and make a list of the materials and tools you will need.

2. Practice Safety First: Always prioritize safety when working with tools. Familiarize yourself with the operation of each tool and follow safety guidelines.

3. Take Your Time: Rushing through cuts and assembly can lead to mistakes. Take your time to ensure accuracy and quality in your work.

4. Experiment with Techniques: Don't be afraid to try different cutting and assembly techniques. Experimentation can lead to discovering more efficient methods.

5. Seek Help When Needed: If you are unsure about a particular technique or tool, seek advice from experienced fabricators or online resources.

Conclusion

Working with 2x2 aluminum extrusion can be a rewarding experience, whether you are building furniture, creating industrial structures, or embarking on a DIY project. By equipping yourself with the right tools and techniques, you can achieve professional-quality results. Remember to prioritize safety and precision in your work, and don't hesitate to experiment with different designs and applications. With the right approach, your projects can not only meet your expectations but also inspire creativity and innovation in your future endeavors.

Frequently Asked Questions

1. What is the best way to cut 2x2 aluminum extrusion?

The best way to cut 2x2 aluminum extrusion is to use a miter saw with a non-ferrous metal cutting blade for clean and precise cuts.

2. Can I drill holes in aluminum extrusion?

Yes, you can drill holes in aluminum extrusion using a drill press or a cordless drill with metal drill bits. It's advisable to use cutting oil for lubrication.

3. What type of fasteners should I use with aluminum extrusion?

Use screws or bolts specifically designed for aluminum, as they have finer threads that grip better in the softer material.

4. How do I ensure accurate measurements when working with aluminum extrusion?

Use a tape measure, square, and marking tools to ensure accurate measurements and markings before cutting.

5. What safety equipment should I wear when working with aluminum extrusion?

Always wear safety glasses, cut-resistant gloves, and ear protection when using power tools to ensure your safety.