Content Menu

● Understanding 80/20 Aluminum Extrusions

● The Importance of Using the Right Tools

● Essential Tools for Working with 80/20 Aluminum Extrusions

>> Cutting Tools

>> Drilling Tools

>> Fastening Tools

>> Assembly Tools

>> Safety Equipment

● Tips for Working with 80/20 Aluminum Extrusions

● Conclusion

● Frequently Asked Questions

>> 1. What is the best way to cut aluminum extrusions?

>> 2. Can I use regular drill bits for aluminum?

>> 3. What type of fasteners should I use with 80/20 aluminum extrusions?

>> 4. Do I need special safety equipment when working with aluminum?

>> 5. How can I ensure my assembly is square?

When embarking on a project that involves 80/20 aluminum extrusions, having the right tools is essential for ensuring precision, efficiency, and safety. Whether you are a seasoned professional or a DIY enthusiast, understanding the tools required to work with these versatile materials can significantly enhance your building experience. This article will explore the various tools needed for working with 80/20 aluminum extrusions, including cutting, drilling, fastening, and assembly tools, as well as tips for using them effectively.

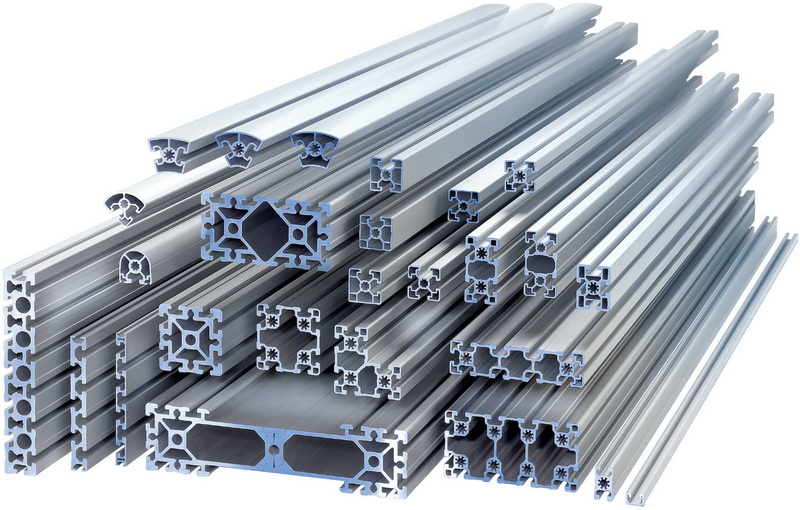

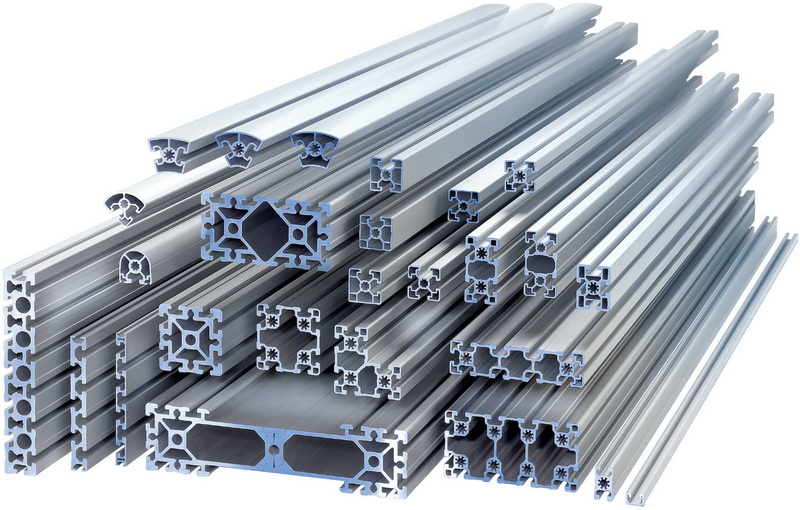

Understanding 80/20 Aluminum Extrusions

80/20 aluminum extrusions are modular framing systems that consist of aluminum profiles with T-slots. These profiles allow for easy assembly and disassembly, making them ideal for a wide range of applications, from industrial machinery to custom furniture. The dimensions of these extrusions can vary, but they typically come in standard sizes, which can be cut to fit specific project requirements.

The versatility of 80/20 aluminum extrusions is one of their most significant advantages. They can be used in various applications, including robotics, workstations, machine frames, and even art installations. The ability to customize the dimensions and configurations of these extrusions makes them a popular choice among engineers, designers, and hobbyists alike.

The Importance of Using the Right Tools

Using the correct tools when working with aluminum extrusions is crucial for several reasons:

1. Precision: Accurate cuts and measurements ensure that components fit together seamlessly. This is particularly important in applications where structural integrity is critical.

2. Safety: Proper tools reduce the risk of accidents and injuries during the construction process. Using the right equipment minimizes the chances of slips, cuts, and other mishaps.

3. Efficiency: The right tools can speed up the assembly process, saving time and effort. Efficient workflows lead to better productivity and higher-quality results.

4. Quality of Work: High-quality tools often yield better results. Investing in good tools can lead to a more professional finish and longer-lasting structures.

Essential Tools for Working with 80/20 Aluminum Extrusions

Cutting Tools

Cutting aluminum extrusions requires specific tools to achieve clean and precise cuts. Here are some of the most commonly used cutting tools:

- Miter Saw: A miter saw equipped with a fine-toothed blade is ideal for making accurate crosscuts and miter cuts in aluminum extrusions. Ensure the blade is designed for cutting non-ferrous metals to prevent damage and achieve a smooth finish.

- Band Saw: A band saw is another excellent option for cutting aluminum. It allows for more intricate cuts and can handle thicker profiles. Use a blade with a high tooth count for the best results.

- Hand Saw: For smaller projects or when portability is essential, a hand saw with a fine-toothed blade can be used. However, this method requires more effort and may not yield as clean a cut as powered tools.

Drilling Tools

Drilling holes in aluminum extrusions is often necessary for fastening components together. Here are the tools you will need:

- Drill Press: A drill press provides stability and precision when drilling holes in aluminum. It allows for consistent depth and angle, which is crucial for creating accurate holes.

- Cordless Drill: A cordless drill is versatile and can be used for various tasks, including drilling holes and driving screws. Ensure you use drill bits specifically designed for metal to avoid dulling.

- Drill Bits: Use high-speed steel (HSS) drill bits for drilling aluminum. These bits are designed to cut through metal efficiently and are less likely to break or wear out quickly.

Fastening Tools

Fastening is a critical step in assembling aluminum extrusions. The following tools will help you secure your components effectively:

- T-Nuts: T-nuts are essential for fastening components to the T-slots of aluminum extrusions. They slide into the slot and provide a threaded hole for screws.

- Bolts and Screws: Use bolts and screws that fit the T-nuts and are appropriate for the load requirements of your project. Stainless steel or aluminum fasteners are recommended for durability.

- Wrenches: A set of wrenches is necessary for tightening bolts and screws. Consider using a torque wrench to ensure that fasteners are tightened to the correct specifications.

Assembly Tools

Once you have cut, drilled, and fastened your aluminum extrusions, you will need tools for assembly:

- Square: A carpenter's square is essential for ensuring that your frames are square and true. This tool helps you check angles and alignments during assembly.

- Level: A level is crucial for ensuring that your assembly is straight and plumb. This tool helps prevent structural issues in your final product.

- Clamps: Clamps are useful for holding components in place while you fasten them together. They provide stability and prevent movement during assembly.

Safety Equipment

Safety should always be a priority when working with tools and materials. Here are some essential safety items:

- Safety Glasses: Protect your eyes from metal shavings and debris while cutting and drilling.

- Hearing Protection: Use earplugs or earmuffs when operating loud machinery, such as saws and drills.

- Gloves: Wear gloves to protect your hands from sharp edges and hot surfaces.

Tips for Working with 80/20 Aluminum Extrusions

1. Measure Twice, Cut Once: Always double-check your measurements before cutting to avoid mistakes and wasted material.

2. Use a Stop Block: When making multiple cuts of the same length, use a stop block to ensure consistency and accuracy.

3. Deburr Edges: After cutting, use a deburring tool or file to smooth sharp edges. This will prevent injuries and ensure a better fit during assembly.

4. Plan Your Layout: Before starting your project, sketch out your design and plan the layout of your extrusions. This will help you visualize the final product and identify any potential issues.

5. Take Your Time: Rushing through the process can lead to mistakes. Take your time to ensure each step is done correctly.

Conclusion

Working with 80/20 aluminum extrusions can be a rewarding experience, especially when you have the right tools at your disposal. From cutting and drilling to fastening and assembly, each tool plays a vital role in the success of your project. By investing in quality tools and following best practices, you can create sturdy and functional structures that meet your needs. Whether you are building a custom workstation, a machine frame, or a unique art installation, the versatility of 80/20 aluminum extrusions combined with the right tools will help you achieve your goals efficiently and effectively.

Frequently Asked Questions

1. What is the best way to cut aluminum extrusions?

The best way to cut aluminum extrusions is to use a miter saw or band saw with a fine-toothed blade designed for non-ferrous metals. This ensures clean cuts and minimizes burrs.

2. Can I use regular drill bits for aluminum?

While you can use regular drill bits, it is recommended to use high-speed steel (HSS) drill bits specifically designed for metal to achieve better results and prolong the life of the bits.

3. What type of fasteners should I use with 80/20 aluminum extrusions?

Use T-nuts, bolts, and screws that are compatible with the T-slots of the extrusions. Stainless steel or aluminum fasteners are ideal for durability and corrosion resistance.

4. Do I need special safety equipment when working with aluminum?

Yes, it is important to wear safety glasses, hearing protection, and gloves to protect yourself from potential hazards such as metal shavings, loud noises, and sharp edges.

5. How can I ensure my assembly is square?

Use a carpenter's square to check angles and alignments during assembly. This will help ensure that your frame is square and true, which is essential for structural integrity.