Content Menu

● Understanding 20/20 Aluminum Extrusion

● Essential Tools for Working with 20/20 Aluminum Extrusion

>> Cutting Tools

>> Drilling Tools

>> Fastening Tools

>> Measuring and Marking Tools

>> Assembly Tools

>> Safety Gear

● Tips for Working with 20/20 Aluminum Extrusion

● Conclusion

● Frequently Asked Questions

>> 1. What is the best way to cut 20/20 aluminum extrusion?

>> 2. Can I use a regular drill for aluminum extrusion?

>> 3. What type of fasteners should I use with aluminum extrusion?

>> 4. How do I ensure my assembly is square?

>> 5. Is it necessary to wear safety gear when working with aluminum extrusion?

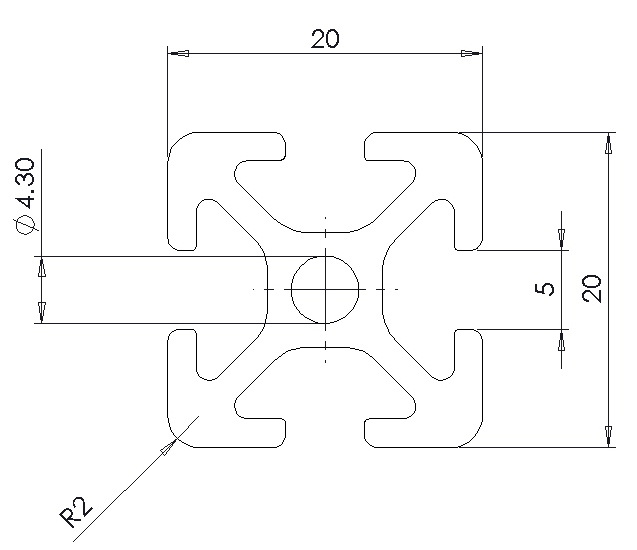

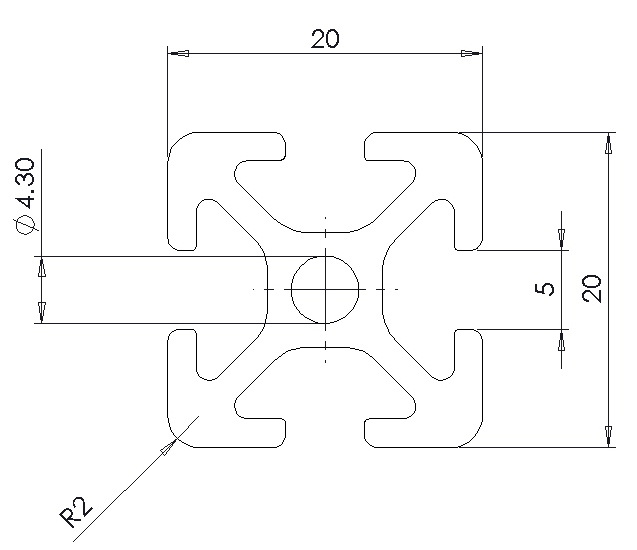

Understanding 20/20 Aluminum Extrusion

Working with 20/20 aluminum extrusion can be an exciting and rewarding experience, especially for DIY enthusiasts, engineers, and hobbyists. This versatile material is widely used in various applications, from building custom furniture to creating complex machinery frames. However, to work effectively with 20/20 aluminum extrusion, having the right tools is essential.

The term "20/20" refers to the dimensions of the extrusion profile, which is 20mm by 20mm. This size is part of a modular system that allows for easy assembly and customization. The aluminum material is lightweight, strong, and resistant to corrosion, making it ideal for various applications. Its modular nature means that it can be easily adapted to different projects, whether you are constructing a simple frame or a more complex structure.

Essential Tools for Working with 20/20 Aluminum Extrusion

Cutting Tools

One of the first steps in working with aluminum extrusion is cutting the profiles to the desired lengths. Here are some cutting tools you might consider:

- Miter Saw: A miter saw with a fine-toothed blade is ideal for making precise cuts at various angles. It provides clean edges and minimizes the risk of burrs. When using a miter saw, ensure that the blade is sharp and designed for cutting metal to achieve the best results.

- Band Saw: A band saw is another excellent option for cutting aluminum extrusion. It allows for more intricate cuts and can handle thicker profiles. Band saws are particularly useful for making curved cuts or when working with larger pieces of aluminum.

- Hand Saw: For smaller projects, a hand saw with a fine-toothed blade can be sufficient. It's a more manual approach but can be effective for simple cuts. When using a hand saw, take your time to ensure straight cuts and avoid damaging the material.

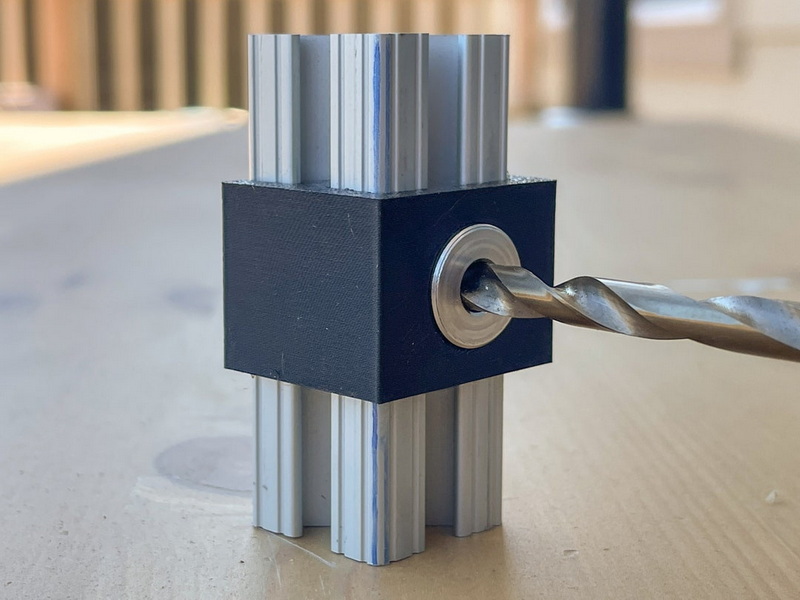

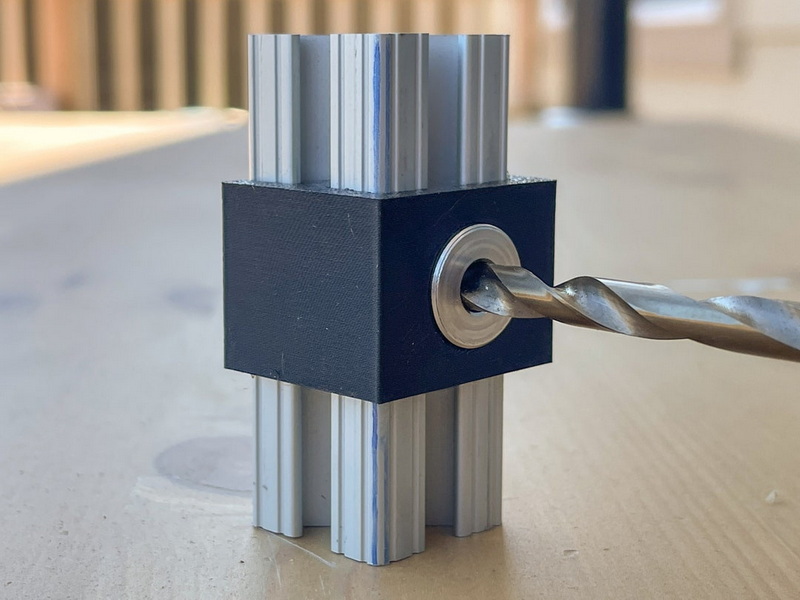

Drilling Tools

Drilling is often necessary for creating holes in the aluminum extrusion for fasteners or other components. Here are some tools to consider:

- Cordless Drill: A cordless drill is versatile and can be used for various tasks, including drilling holes and driving screws. Make sure to use drill bits designed for metal, as they are specifically engineered to handle the hardness of aluminum.

- Drill Press: For more precision, a drill press can be used. It allows for consistent hole placement and depth, which is especially useful for larger projects. A drill press is particularly beneficial when you need to drill multiple holes in a straight line or at specific intervals.

Fastening Tools

Once the pieces are cut and drilled, you'll need to join them together. Here are some fastening tools:

- Screwdriver Set: A good set of screwdrivers is essential for driving screws into the aluminum profiles. Look for a set that includes both Phillips and flathead screwdrivers. Having a variety of sizes will ensure you can handle different types of screws.

- Hex Key Set: Many aluminum extrusion systems use hex bolts, so having a hex key (Allen wrench) set is crucial for assembly. These tools allow you to tighten or loosen bolts easily, ensuring a secure fit.

- Rivet Gun: For a more permanent solution, a rivet gun can be used to secure pieces together. This is especially useful for creating strong joints in structural applications. Riveting is a great option when you want to avoid using visible fasteners.

Measuring and Marking Tools

Accurate measurements are vital when working with aluminum extrusion. Here are some tools to help you measure and mark:

- Tape Measure: A standard tape measure is essential for measuring lengths accurately. Look for a tape measure that has both metric and imperial measurements for versatility.

- Square: A carpenter's square or framing square can help ensure that your cuts are straight and your angles are correct. This tool is invaluable for checking the squareness of your assembly.

- Marking Tool: A fine-tip marker or scribe can be used to mark cut lines on the aluminum extrusion. Using a scribe can help create more precise lines that are easier to follow when cutting.

Assembly Tools

Once you have all your pieces cut and drilled, it's time to assemble them. Here are some tools that can help:

- Clamps: Clamps are essential for holding pieces in place while you fasten them together. Look for adjustable clamps that can accommodate different sizes of profiles. Using clamps will help ensure that your assembly remains stable while you work.

- Level: A level ensures that your assembly is straight and true, which is especially important for larger structures. Using a level during assembly can prevent issues later on, such as misalignment.

- Workbench: A sturdy workbench provides a stable surface for cutting, drilling, and assembling your aluminum extrusion projects. A well-organized workspace can significantly improve your efficiency and safety.

Safety Gear

Safety should always be a priority when working with tools. Here are some essential safety items:

- Safety Glasses: Protect your eyes from metal shavings and debris while cutting and drilling. Safety glasses are a must-have to prevent injuries.

- Hearing Protection: If you're using power tools, consider wearing ear protection to guard against noise. Prolonged exposure to loud tools can lead to hearing loss.

- Gloves: Wearing gloves can protect your hands from sharp edges and provide a better grip on tools. Choose gloves that are cut-resistant for added safety.

Tips for Working with 20/20 Aluminum Extrusion

- Plan Your Design: Before starting, sketch out your design and plan the cuts and assembly. This will save time and materials. Having a clear plan will help you visualize the final product and identify any potential issues early on.

- Measure Twice, Cut Once: Always double-check your measurements before cutting to avoid mistakes. This age-old adage is especially true when working with materials like aluminum, where errors can be costly.

- Use the Right Blade: Ensure that you are using the correct blade for cutting aluminum. A fine-toothed blade will provide cleaner cuts. Using the wrong blade can lead to rough edges and increased wear on your tools.

- Deburr Edges: After cutting, use a deburring tool or file to smooth out any sharp edges. This will make handling safer and improve the fit of joints. Deburring is an important step that should not be overlooked.

- Test Fit Before Final Assembly: Before permanently fastening pieces together, do a test fit to ensure everything aligns correctly. This step can save you from having to disassemble and redo parts of your project.

Conclusion

Working with 20/20 aluminum extrusion can be a fulfilling endeavor, especially when equipped with the right tools and knowledge. From cutting and drilling to fastening and assembling, each step requires careful attention to detail and the appropriate equipment. By following the tips outlined in this article, you can create strong, functional structures that meet your needs. Whether you are building a simple frame or a complex assembly, the right tools and techniques will ensure your success in working with aluminum extrusion.

Frequently Asked Questions

1. What is the best way to cut 20/20 aluminum extrusion?

The best way to cut 20/20 aluminum extrusion is to use a miter saw with a fine-toothed blade for clean, precise cuts. A band saw can also be effective for more intricate cuts.

2. Can I use a regular drill for aluminum extrusion?

Yes, a regular cordless drill can be used, but make sure to use drill bits specifically designed for metal to achieve the best results. This will help prevent damage to both the drill and the material.

3. What type of fasteners should I use with aluminum extrusion?

Hex bolts and screws are commonly used with aluminum extrusion. Ensure they are compatible with the profile you are using, and consider using T-nuts for a secure fit.

4. How do I ensure my assembly is square?

Use a carpenter's square to check the angles during assembly. Adjust as necessary before fastening. This will help ensure that your final structure is stable and visually appealing.

5. Is it necessary to wear safety gear when working with aluminum extrusion?

Yes, wearing safety glasses, gloves, and hearing protection is important to ensure your safety while working with tools and materials. Always prioritize safety to prevent accidents.