Content Menu

● Understanding the Role of an Aluminum Extrusion Press Operator

● Essential Skills for an Aluminum Extrusion Press Operator

>> 1. Technical Proficiency

>> 2. Attention to Detail

>> 3. Problem-Solving Skills

>> 4. Physical Stamina

>> 5. Safety Consciousness

● Educational Requirements and Certifications

● Career Advancement Opportunities

● The Future of Aluminum Extrusion Press Operators

● Conclusion

● FAQ

>> 1. What is the typical aluminum extrusion press operator job description?

>> 2. What qualifications are needed to become an aluminum extrusion press operator?

>> 3. What are the primary responsibilities of an aluminum extrusion press operator?

>> 4. What career advancement opportunities are available for aluminum extrusion press operators?

>> 5. How is technology changing the role of aluminum extrusion press operators?

● Citations:

Aluminum extrusion press operators play a crucial role in the manufacturing industry, operating and managing equipment that shapes aluminum into various profiles used in construction, automotive, and other sectors.[2] This article will explore the essential skills required for this challenging yet rewarding career, providing insights into the job description, necessary qualifications, and potential career paths.

Understanding the Role of an Aluminum Extrusion Press Operator

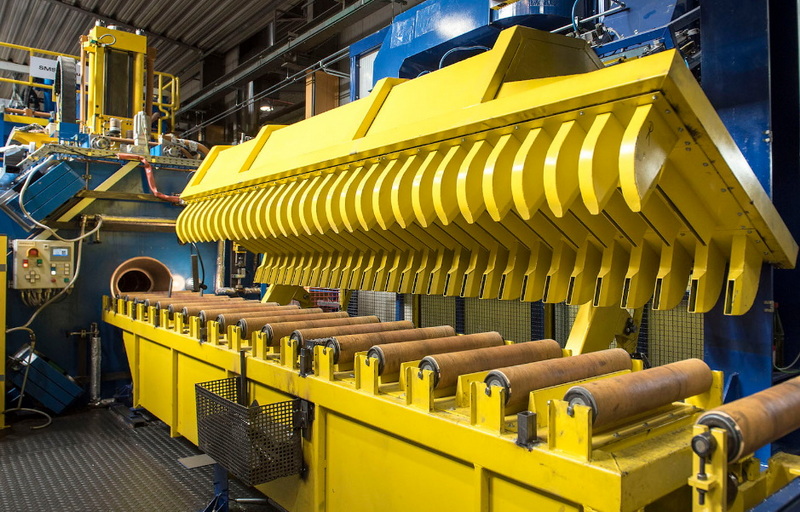

Before delving into the required skills, it's important to understand what an aluminum extrusion press operator does. The process begins with heating aluminum billets until they are malleable, then using a hydraulic press to push the aluminum through a shaped die. The result is a continuous profile that can be cut to length for various applications.[2]

Here's a visual representation of the aluminum extrusion process:

The process typically involves the following steps:

1. Heating the Billet: The aluminum is heated to approximately 900°F (482°C) to make it pliable.

2. Extrusion: A hydraulic press pushes the heated aluminum through a die, forming it into the desired shape.

3. Cooling: The extruded profile is cooled, often in a water bath, to set its shape.

4. Cutting and Finishing: The extruded aluminum is cut to length and may undergo additional finishing processes such as anodizing or painting.[2]

Now that we understand the process, let's explore the skills required for this job.

Essential Skills for an Aluminum Extrusion Press Operator

To be successful as an aluminum extrusion press operator, you should develop several key skills:

1. Technical Proficiency: Understanding machinery operation and maintenance is essential.

2. Attention to Detail: Precision is critical; operators must monitor machine settings closely.

3. Problem-Solving Skills: The ability to troubleshoot issues quickly during production is vital.

4. Physical Stamina: Operators often handle heavy materials and equipment.

5. Safety Consciousness: Adhering to safety protocols helps prevent accidents in the workplace.[2]

Let's delve deeper into each of these skills and explore why they are crucial for the role of an aluminum extrusion press operator.

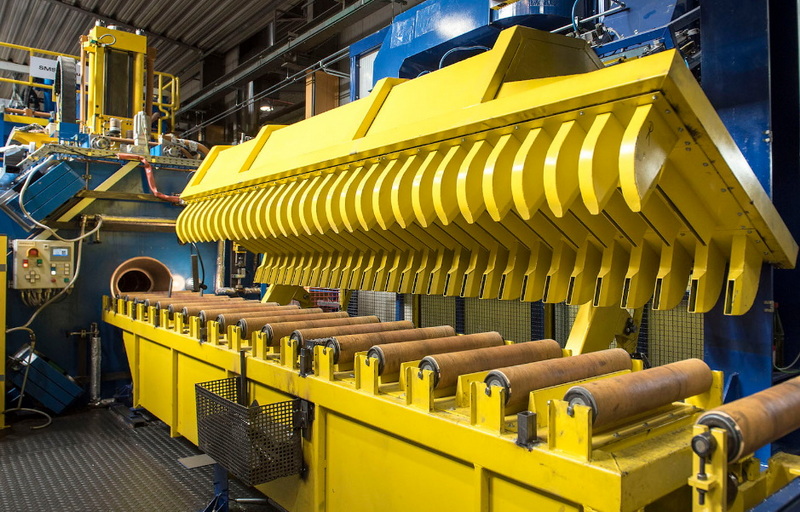

1. Technical Proficiency

Technical proficiency is paramount in this role. Operators must be able to:

- Operate the extrusion saw in a safe and productive manner

- Measure and examine extruded products during routine quality checks

- Determine setup procedures according to specifications

- Perform daily and weekly preventative maintenance on the extrusion saw and press area

- Monitor oil levels, change and replace worn tooling, and perform basic cleaning[5]

To illustrate the complexity of the machinery involved, here's a video showcasing an aluminum extrusion press in action:

2. Attention to Detail

Attention to detail is crucial in this role. Operators must:

- Locate defects on extruded products

- Check for conformance to specifications

- Adjust controls as necessary[3]

This level of precision ensures that the final product meets the required quality standards and customer specifications.

3. Problem-Solving Skills

Problem-solving skills are essential for an aluminum extrusion press operator. They must be able to:

- Accurately use ERP systems to document machine rates, scrap rates, and material usage

- Communicate within the team or organization to discuss changes in production schedule or machine issues[5]

These skills help maintain an efficient and lean production environment, ensuring that any issues are quickly identified and resolved.

4. Physical Stamina

The role of an aluminum extrusion press operator can be physically demanding. Operators must:

- Operate cranes and forklifts to move raw material and tooling when needed

- Be able to perform various duties and responsibilities as needed to cover vacations, absences, breaks, etc.[5]

This physical aspect of the job requires operators to be in good physical condition and able to handle the demands of a manufacturing environment.

5. Safety Consciousness

Safety is paramount in any manufacturing environment. Aluminum extrusion press operators must:

- Follow company policies, procedures, and directives regarding safety and standards of workplace behavior

- Inform production leaders of any maintenance or safety issues

- Ensure proper use of personal protective equipment (PPE)[1]

A strong commitment to safety helps prevent accidents and ensures a healthy work environment for all employees.

Educational Requirements and Certifications

While a college degree is not always required for this position, certain educational qualifications can be beneficial:

- A high school diploma or GED is typically the minimum educational requirement

- Courses in mathematics, physics, and shop classes can provide foundational knowledge

- Vocational or technical training programs in manufacturing technology, mechanical engineering, or industrial technology can enhance job prospects[2]

Additionally, obtaining certification from recognized industry organizations such as the Aluminum Extruders Council (AEC) can demonstrate your commitment to the profession and make you more attractive to employers.[2]

Career Advancement Opportunities

As you gain experience as an aluminum extrusion press operator, there are numerous opportunities for advancement within the field:

- Supervisory Roles: Experienced operators can move into supervisory positions overseeing teams of operators.

- Quality Control: Operators may transition into quality control roles, ensuring that products meet industry standards.

- Specialized Technical Positions: Further education may lead to specialized roles in areas such as CNC operation or robotics.[2]

These advancement opportunities highlight the potential for long-term career growth in this field.

The Future of Aluminum Extrusion Press Operators

The aluminum extrusion industry has seen significant advancements over recent years, driven by technological innovations aimed at improving efficiency and sustainability. With the increasing demand for lightweight materials in industries such as automotive and construction, skilled operators will find ample job opportunities as companies seek experts who can manage sophisticated extrusion processes effectively.[2]

Some of the emerging trends in aluminum extrusion technology include:

1. Artificial Intelligence Integration

2. Advanced Cooling Techniques

3. Hybrid Extrusion Techniques

4. Nano-Coating Technologies

These advancements underscore the importance of continuous learning and adaptability in this field.

Conclusion

The role of an aluminum extrusion press operator is both challenging and rewarding, requiring a unique blend of technical skills, physical stamina, and attention to detail. As the industry continues to evolve with new technologies and processes, the demand for skilled operators remains strong.

Becoming an aluminum extrusion press operator requires a combination of education, hands-on experience, and skill development. With dedication and continuous learning, you can build a successful career in this dynamic field that plays a crucial role in modern manufacturing.[2]

By developing the essential skills outlined in this article and staying abreast of industry advancements, aspiring aluminum extrusion press operators can position themselves for success in this vital manufacturing role.

FAQ

1. What is the typical aluminum extrusion press operator job description?

An aluminum extrusion press operator is responsible for operating the extrusion press at the best possible speed while maintaining good quality extrusion. They handle the movement of material to and from the saw area, monitor and check the quality of extrusion according to ISO standards, and ensure production targets are met in a multi-press operation.[1]

2. What qualifications are needed to become an aluminum extrusion press operator?

Qualifications typically include:

- High school diploma or general education degree (GED) preferred

- 1 to 2 years experience in a production environment

- Ability to read and understand shop orders and prints

- Reliability with a good work ethic and attitude

- Mechanical aptitude[1]

3. What are the primary responsibilities of an aluminum extrusion press operator?

Primary responsibilities include:

- Selecting machine dies

- Determining setup procedures

- Drawing or pressing metal into shapes and diameters

- Reeling extruded products into rolls

- Specifying lengths and weights of rolls

- Replacing worn dies

- Setting controls to regulate vacuum, air pressure, sizing rings, and temperature

- Synchronizing speed of extrusion

- Reading and interpreting blueprints and drawings[3]

4. What career advancement opportunities are available for aluminum extrusion press operators?

Career advancement opportunities include:

- Moving into supervisory roles overseeing teams of operators

- Transitioning into quality control roles

- Pursuing specialized technical positions in areas such as CNC operation or robotics with further education[2]

5. How is technology changing the role of aluminum extrusion press operators?

Technology is significantly impacting the aluminum extrusion industry with advancements aimed at improving efficiency and sustainability. Emerging trends include the integration of artificial intelligence, advanced cooling techniques, hybrid extrusion techniques, and nano-coating technologies. These advancements require operators to continuously update their skills and adapt to new processes and equipment.[2]

Citations:

[1] https://www.ziprecruiter.com/c/Momentum-Manufacturing-Group-Engineered-Extrusions/Job/Aluminum-Extrusion-Operator-Press-Operator-Night-Shift/-in-Franklin,NH?jid=ea9bb883e45c592e

[2] https://www.yjing-extrusion.com/how-to-become-an-aluminum-extrusion-press-operator.html

[3] https://diversityjobs.com/job-descriptions/extruding-machine-operator-job-description

[4] https://www.extrusion.net

[5] https://www.indeed.com/q-aluminum-extrusion-press-operator-jobs.html

[6] https://almag.com/wp-content/uploads/2015/04/Extrusion-Press-Supervisor-1.pdf

[7] https://www.rssinc.com/blog/what-is-an-extrusion-machine-operator/

[8] https://www.keymarkcorp.com/jobs/industrial-manufacturing-machinery-maintenance-technician-2/