Content Menu

● Understanding the Role

● Key Responsibilities

● Essential Skills Required

>> Technical Skills

>> Managerial Skills

>> Analytical Skills

● Education and Experience Requirements

● Tools and Technologies Used

● Challenges Faced by Die Shop Managers

● Future Trends in Aluminum Extrusion

● Developing Soft Skills

● The Importance of Continuous Learning

● Conclusion

● FAQs

>> 1. What qualifications do I need to become an Aluminum Extrusion Die Shop Manager?

>> 2. What are the primary responsibilities of a Die Shop Manager?

>> 3. How important is experience in aluminum extrusion for this role?

>> 4. What tools do Die Shop Managers commonly use?

>> 5. What challenges do Die Shop Managers face?

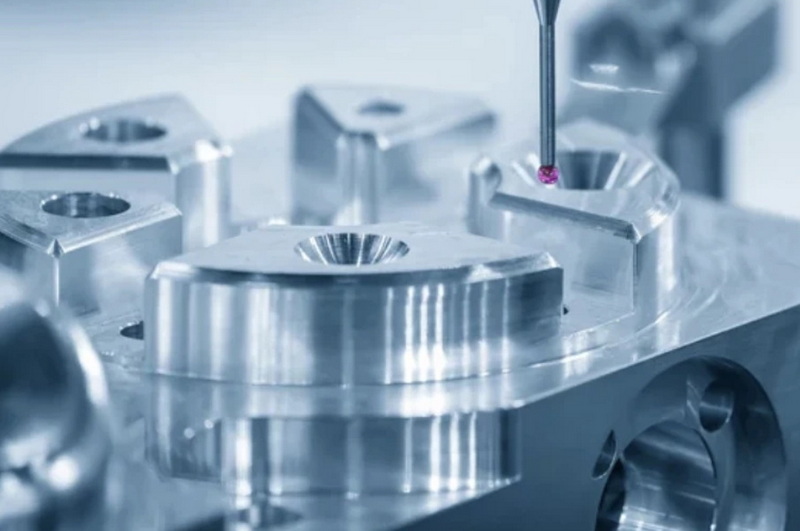

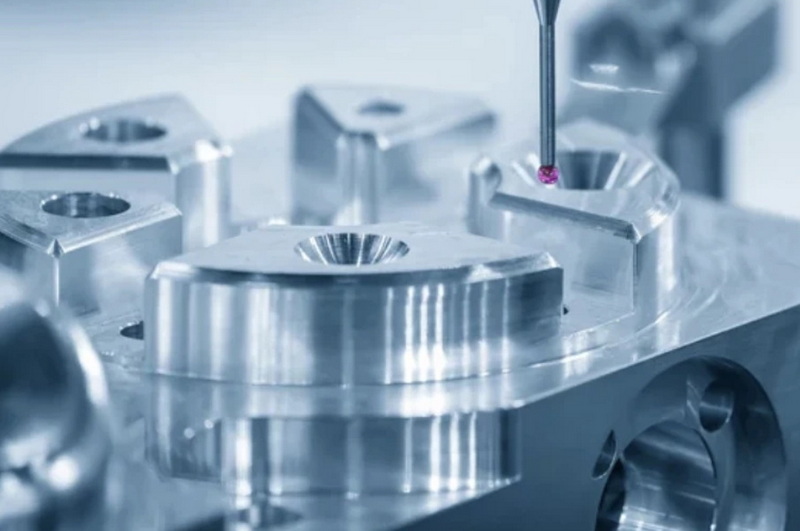

The role of an Aluminum Extrusion Die Shop Manager is pivotal in the manufacturing process of aluminum products. This position requires a unique blend of technical expertise, managerial skills, and industry knowledge. In this article, we will explore the essential skills and qualifications needed for this role, providing insights into the daily responsibilities and challenges faced by professionals in this field.

Understanding the Role

An Aluminum Extrusion Die Shop Manager oversees the die shop operations, ensuring that all processes related to die maintenance, repair, and production run smoothly. This role is crucial for maintaining product quality and operational efficiency. The manager must coordinate with various departments, including production, quality control, and engineering, to meet production goals.

Key Responsibilities

- Die Maintenance and Repair: Overseeing the maintenance and repair of extrusion dies to ensure they meet production specifications.

- Team Management: Leading a team of die makers and technicians, fostering a collaborative work environment.

- Process Improvement: Identifying areas for process improvement to enhance productivity and reduce waste.

- Quality Assurance: Ensuring that all produced dies meet quality standards and specifications.

- Budget Management: Managing budgets related to die shop operations, including labor and materials.

Essential Skills Required

To excel in the role of an Aluminum Extrusion Die Shop Manager, candidates must possess a variety of skills:

Technical Skills

- Die Design Knowledge: Understanding die design principles is critical. This includes knowledge of materials used in die manufacturing, such as H13 steel, which is commonly used due to its high wear resistance.

- Extrusion Process Expertise: A deep understanding of the aluminum extrusion process is necessary. This includes familiarity with preheating billets, hydraulic ram operations, and cooling methods.

- Precision Measurement Skills: Proficiency in using precision measuring instruments to ensure that dies are manufactured within strict tolerances.

- Material Science Knowledge: Understanding the properties of aluminum alloys is essential for selecting the right materials for specific applications. Knowledge about how different alloys respond to extrusion processes can significantly impact product quality.

Managerial Skills

- Leadership Abilities: Strong leadership skills are essential for managing a diverse team. This includes motivating staff, resolving conflicts, and fostering a positive workplace culture.

- Project Management: Ability to manage multiple projects simultaneously while adhering to deadlines and budget constraints.

- Communication Skills: Excellent verbal and written communication skills are necessary for effective collaboration with team members and other departments.

- Conflict Resolution: The ability to mediate disputes between team members or departments efficiently is crucial for maintaining a harmonious work environment.

Analytical Skills

- Problem-Solving Abilities: The capacity to identify problems quickly and develop effective solutions is crucial in a fast-paced manufacturing environment.

- Data Analysis: Familiarity with data analysis tools can help in assessing production metrics and making informed decisions regarding process improvements.

- Root Cause Analysis: Skills in identifying the root causes of defects or inefficiencies can lead to more sustainable solutions rather than temporary fixes.

Education and Experience Requirements

Typically, candidates for Aluminum Extrusion Die Shop Manager roles are expected to have:

- A bachelor's degree in engineering, manufacturing management, or a related field.

- Several years of experience in aluminum extrusion or a related manufacturing environment.

- Previous experience in a supervisory or managerial role is highly advantageous.

Tools and Technologies Used

In addition to the skills mentioned above, familiarity with specific tools and technologies is beneficial:

- CAD Software: Proficiency in computer-aided design (CAD) software for designing dies. Knowledge of software such as AutoCAD or SolidWorks can be particularly advantageous.

- ERP Systems: Knowledge of enterprise resource planning (ERP) systems can assist in managing resources effectively. Familiarity with systems like SAP or Oracle can streamline operations significantly.

- Quality Control Tools: Understanding how to use various quality control tools to monitor production processes. Tools such as coordinate measuring machines (CMM) are often used for precise measurements.

Challenges Faced by Die Shop Managers

Die shop managers face several challenges that require adaptability and resilience:

- Meeting Production Demands: Balancing production schedules while ensuring quality can be difficult, especially during peak times when orders surge unexpectedly.

- Technological Advancements: Keeping up with new technologies in die design and manufacturing processes requires continuous learning. Managers must stay informed about advancements like 3D printing technology for rapid prototyping of dies.

- Workforce Management: Managing a diverse workforce with varying skill levels can lead to challenges in training and development. Effective training programs must be established to upskill employees regularly.

- Supply Chain Issues: Fluctuations in raw material availability can impact production schedules. Managers need to develop contingency plans to mitigate these risks effectively.

Future Trends in Aluminum Extrusion

As industries evolve, so do the demands placed on aluminum extrusion processes. Future trends include:

- Sustainability Practices: Increasing focus on sustainable manufacturing practices will require managers to adapt their processes accordingly. This includes recycling scrap aluminum and reducing energy consumption during extrusion processes.

- Automation: The rise of automation technology will change how die shops operate, necessitating new skills among managers. Embracing Industry 4.0 principles can lead to smarter factories with interconnected systems that enhance efficiency.

- Advanced Materials Development: Research into new aluminum alloys that offer improved performance characteristics will influence die design strategies. Managers must stay abreast of these developments to remain competitive.

Developing Soft Skills

While technical knowledge is critical for success as an Aluminum Extrusion Die Shop Manager, soft skills are equally important:

- Emotional Intelligence (EQ): High EQ enables managers to understand their team's emotions better, leading to improved morale and productivity.

- Adaptability: The ability to adapt quickly to changing circumstances or unexpected challenges is vital in today's dynamic manufacturing environment.

- Time Management: Effective time management skills help managers prioritize tasks efficiently, ensuring that critical deadlines are met without compromising quality.

The Importance of Continuous Learning

In an industry characterized by rapid change, continuous learning is essential for Aluminum Extrusion Die Shop Managers. Engaging in professional development opportunities such as workshops, seminars, or online courses can enhance both technical competencies and managerial capabilities. Networking with other professionals through industry associations can also provide valuable insights into best practices and emerging trends.

Conclusion

The role of an Aluminum Extrusion Die Shop Manager is multifaceted and requires a combination of technical expertise, managerial skills, and problem-solving abilities. As the industry continues to evolve with technological advancements and sustainability initiatives, the demand for skilled professionals in this field will only increase. Those looking to pursue a career as an Aluminum Extrusion Die Shop Manager should focus on developing both their technical knowledge and leadership capabilities to succeed in this dynamic environment.

By understanding the complexities involved in die shop management—from overseeing production processes to fostering team collaboration—aspiring managers can prepare themselves for the challenges ahead. The future holds exciting opportunities for those who are willing to adapt and grow within this vital sector of manufacturing.

FAQs

1. What qualifications do I need to become an Aluminum Extrusion Die Shop Manager?

To become an Aluminum Extrusion Die Shop Manager, you typically need a bachelor's degree in engineering or manufacturing management along with several years of relevant experience in the aluminum extrusion industry.

2. What are the primary responsibilities of a Die Shop Manager?

The primary responsibilities include overseeing die maintenance and repair operations, managing staff, ensuring quality assurance, budgeting for die shop operations, and implementing process improvements.

3. How important is experience in aluminum extrusion for this role?

Experience in aluminum extrusion is crucial as it provides practical knowledge of the processes involved, which is essential for effective management of die shop operations.

4. What tools do Die Shop Managers commonly use?

Die Shop Managers commonly use CAD software for designing dies, ERP systems for resource management, and various precision measuring instruments for quality control.

5. What challenges do Die Shop Managers face?

Die Shop Managers face challenges such as meeting production demands while ensuring quality, keeping up with technological advancements, managing a diverse workforce effectively, and addressing supply chain issues promptly.