Content Menu

● Introduction

● Understanding Rivnut Sizes For Van Conversion

● Aluminum Extrusion Installation Techniques

● Van Build Fastening Methods

● Threaded Insert Options For Vans

● DIY Van Cabinets With Extrusions

● Sprinter Van 8020 Mounting

● Rivet Nut Selection Guide

● Van Interior Construction Materials

● Extruded Aluminum Framing Systems

● Secure Attachment Methods For Vans

● Conclusion

● Frequently Asked Questions

>> Q1: What size rivnuts should I use for attaching aluminum extrusion to my van?

>> Q2: How do I install rivnuts in my van?

>> Q3: Can I use aluminum extrusion for my entire van interior frame?

>> Q4: How do I cut aluminum extrusion for my van build?

>> Q5: Are there alternatives to rivnuts for attaching components in a van conversion?

Introduction

Van conversions have become increasingly popular in recent years, with more people embracing the nomadic lifestyle and the freedom it offers. One of the key aspects of a successful van build is choosing the right materials and fastening methods to create a sturdy, functional, and aesthetically pleasing interior. In this comprehensive guide, we'll explore the world of rivnuts and aluminum extrusion, two essential components that can elevate your van conversion project to the next level.

Understanding Rivnut Sizes For Van Conversion

Rivnuts, also known as rivet nuts or threaded inserts, are an ingenious fastening solution that allows you to create strong, threaded attachment points in thin materials. When it comes to van conversions, rivnuts are particularly useful for attaching various components to the van's body without compromising its structural integrity.

The most common rivnut sizes used in van conversions are:

1. 1/4"-20: This size is widely used for general-purpose applications and can handle most lightweight to medium-weight attachments.

2. 5/16"-18: Ideal for heavier-duty applications where extra strength is required.

3. M6 and M8: These metric sizes are often used in European vans and for certain specialized components.

When selecting the appropriate rivnut size for your project, consider the weight of the item you're attaching, the thickness of the van's sheet metal, and the available space for installation.

Aluminum Extrusion Installation Techniques

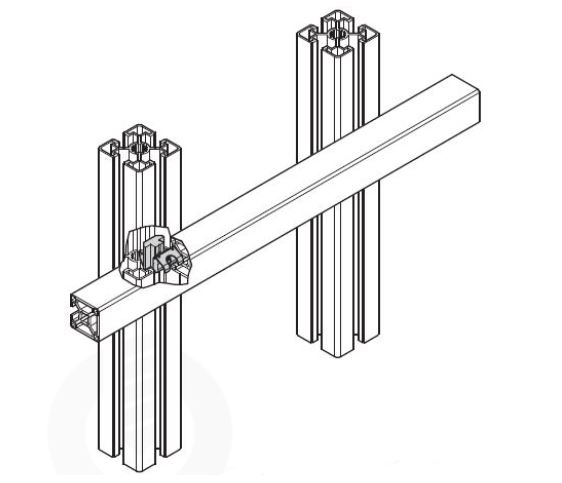

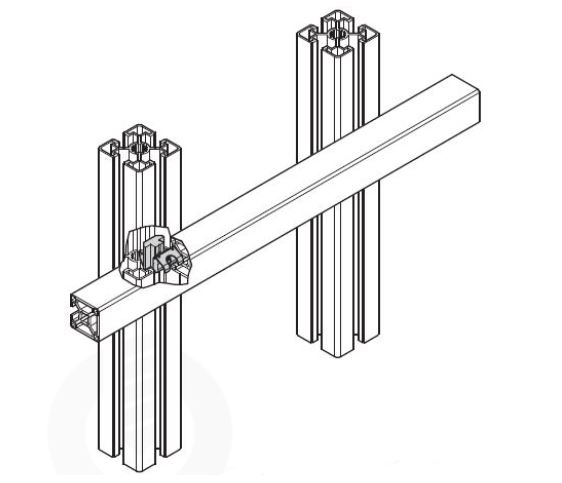

Aluminum extrusion, particularly the 80/20 system, has revolutionized van conversions by providing a versatile, lightweight, and strong framing solution. These modular aluminum profiles can be used to create everything from bed frames to cabinet structures and even entire interior layouts.

To install aluminum extrusion in your van:

1. Plan your layout carefully, considering the van's dimensions and your specific needs.

2. Cut the extrusions to size using a miter saw with a blade designed for cutting aluminum.

3. Use corner brackets, joining plates, and other specialized connectors to assemble your frame.

4. Attach the frame to the van's body using rivnuts or other secure fastening methods.

Van Build Fastening Methods

While rivnuts are an excellent option for attaching components to your van, there are several other fastening methods worth considering:

1. Self-tapping screws: These can be used for lightweight applications but may not provide the same level of strength as rivnuts.

2. Welding: For those with welding skills, this can provide an extremely strong connection but is permanent and requires specialized equipment.

3. VHB tape: This high-strength adhesive tape can be used for certain applications where drilling isn't possible or desirable.

4. Bolts and washers: When used in conjunction with rivnuts, these provide a secure and removable attachment point.

Threaded Insert Options For Vans

While rivnuts are the most common type of threaded insert used in van conversions, there are other options available:

1. Plus nuts: These provide a larger bearing surface and can be useful in situations where the load is distributed over a wider area.

2. Nutserts: Similar to rivnuts but with a slightly different installation process.

3. Weld nuts: These are welded directly to the van's body, providing an extremely strong connection but requiring welding skills and equipment.

DIY Van Cabinets With Extrusions

One of the most popular applications for aluminum extrusion in van conversions is building custom cabinets. The modular nature of the 80/20 system allows for endless possibilities in terms of design and functionality.

To create DIY van cabinets with extrusions:

1. Design your cabinet layout using 80/20's planning software or a CAD program.

2. Cut your extrusions to size and assemble the frame using corner brackets and joining plates.

3. Attach plywood or other panel materials to create the cabinet sides, top, and bottom.

4. Install drawer slides, hinges, and other hardware as needed.

5. Secure the cabinet to the van's body using rivnuts or other appropriate fastening methods.

Sprinter Van 8020 Mounting

Sprinter vans are a popular choice for conversions due to their spacious interiors and relatively square shape. When mounting 80/20 extrusions in a Sprinter van:

1. Use rivnuts in the van's existing holes or drill new holes as needed.

2. Consider using backing plates for added strength, especially for ceiling-mounted components.

3. Use stainless steel hardware to prevent corrosion.

4. Ensure that your mounting points are properly sealed to prevent water ingress.

Rivet Nut Selection Guide

Choosing the right rivnut for your van conversion project is crucial for ensuring a secure and long-lasting installation. Consider the following factors when selecting rivnuts:

1. Material: Aluminum rivnuts are lightweight but may not be suitable for all applications. Steel rivnuts offer greater strength but are heavier.

2. Thread size and pitch: Ensure that your rivnuts match the bolts you plan to use.

3. Grip range: This refers to the thickness of material the rivnut can securely fasten. Choose a rivnut with a grip range that matches your van's sheet metal thickness.

4. Head style: Flanged rivnuts provide a larger bearing surface, while countersunk rivnuts sit flush with the surface.

Van Interior Construction Materials

In addition to aluminum extrusion and rivnuts, there are several other materials commonly used in van conversions:

1. Plywood: Used for flooring, walls, and cabinet construction.

2. Rigid foam insulation: Provides thermal and sound insulation.

3. Vinyl flooring: Durable and easy to clean.

4. Fabric and upholstery: Used for seating, bedding, and decorative elements.

5. Laminate or solid surface countertops: Provide a durable work surface for kitchens and workspaces.

Extruded Aluminum Framing Systems

While 80/20 is the most well-known extruded aluminum framing system, there are other options available:

1. MakerBeam: A smaller-scale system ideal for lightweight applications.

2. OpenBuilds: Popular in the maker community and suitable for various projects.

3. Bosch Rexroth: A heavy-duty system often used in industrial applications but adaptable for van conversions.

When choosing an extruded aluminum framing system, consider factors such as compatibility with other components, availability of accessories, and overall cost.

Secure Attachment Methods For Vans

Ensuring that all components in your van conversion are securely attached is crucial for safety and longevity. Some best practices for secure attachments include:

1. Use appropriate thread-locking compounds on bolts to prevent loosening due to vibration.

2. Implement redundant fastening methods for critical components, such as combining rivnuts with adhesive or additional mechanical fasteners.

3. Regularly inspect and tighten all fasteners, especially after long trips or off-road adventures.

4. Use load-rated hardware and fasteners for any weight-bearing applications, such as bed frames or overhead storage.

Conclusion

Mastering the use of rivnuts and aluminum extrusion in your van conversion project can significantly enhance the quality, functionality, and durability of your build. By understanding the various sizes, installation techniques, and best practices, you'll be well-equipped to create a custom van interior that meets your specific needs and withstands the rigors of life on the road.

Frequently Asked Questions

Q1: What size rivnuts should I use for attaching aluminum extrusion to my van?

A1: The most common size for attaching aluminum extrusion to vans is 1/4"-20 rivnuts. This size provides a good balance of strength and ease of use for most applications. However, for heavier-duty installations, you may want to consider 5/16"-18 rivnuts.

Q2: How do I install rivnuts in my van?

A2: To install rivnuts, you'll need a rivnut installation tool. First, drill a hole of the appropriate size in your van's sheet metal. Then, place the rivnut in the installation tool, insert it into the hole, and squeeze the tool's handles to compress the rivnut, creating a secure threaded insert.

Q3: Can I use aluminum extrusion for my entire van interior frame?

A3: Yes, it's possible to use aluminum extrusion for your entire van interior frame. Many van builders choose this option due to its versatility, strength, and ease of modification. However, keep in mind that a full aluminum extrusion frame may be more expensive than traditional wood framing.

Q4: How do I cut aluminum extrusion for my van build?

A4: The best way to cut aluminum extrusion is with a miter saw equipped with a blade designed for cutting aluminum. Make sure to wear appropriate safety gear, including eye protection and gloves. For precise cuts, use a stop block or measure carefully before each cut.

Q5: Are there alternatives to rivnuts for attaching components in a van conversion?

A5: Yes, there are several alternatives to rivnuts, including plus nuts, weld nuts, self-tapping screws, and VHB tape. The best choice depends on your specific application, the weight of the component being attached, and your personal preferences. For critical structural elements, it's often best to use a combination of methods for added security.