Content Menu

● What Services Do Top Aluminum Extruder Companies Provide?

● Understanding Aluminum Extrusion

● Key Advantages of Aluminum Extrusion:

● Core Services Offered by Aluminum Extruder Companies

● Design and Engineering Support

>> Key Aspects of Design and Engineering Support:

● Extrusion Manufacturing

>> Key Considerations in Extrusion Manufacturing:

● Fabrication Services

>> Common Fabrication Services Include:

● Finishing Services

>> Popular Finishing Services:

● Assembly and Packaging

>> Typical Assembly and Packaging Services:

● Supply Chain Management

>> Key Aspects of Supply Chain Management:

● Value-Added Services

>> Examples of Value-Added Services:

● Emerging Trends in Aluminum Extrusion

>> Automation and Robotics

>> Artificial Intelligence (AI)

>> Smart Manufacturing

>> 3D Printing Integration

>> Advanced Die Design

● Industries Served by Aluminum Extruder Companies

● Choosing the Right Aluminum Extruder Company

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What are common aluminum alloys used in extrusion?

>> 2. What is the difference between direct & indirect extrusion?

>> 3. How does anodizing improve aluminum extrusions?

>> 4. What are typical lead times for aluminum extrusion projects?

>> 5. Can aluminum extrusions be recycled?

● Citations:

What Services Do Top Aluminum Extruder Companies Provide?

Aluminum extrusion is a versatile manufacturing process used to create a wide array of products across numerous industries. "Aluminum extruder companies" play a critical role in this process, offering a comprehensive suite of services that extend far beyond simply shaping aluminum. These services encompass design, engineering, fabrication, finishing, and assembly, providing clients with end-to-end solutions for their specific needs. This article explores the diverse services offered by top "aluminum extruder companies", highlighting their capabilities and the value they bring to their customers.

Understanding Aluminum Extrusion

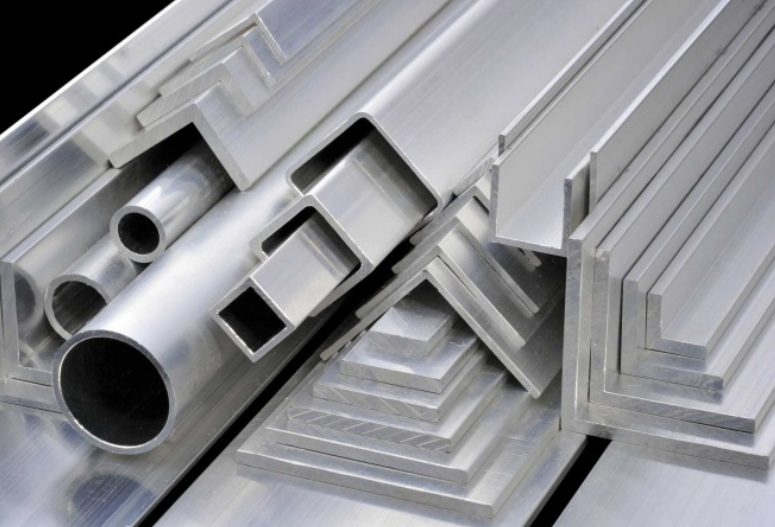

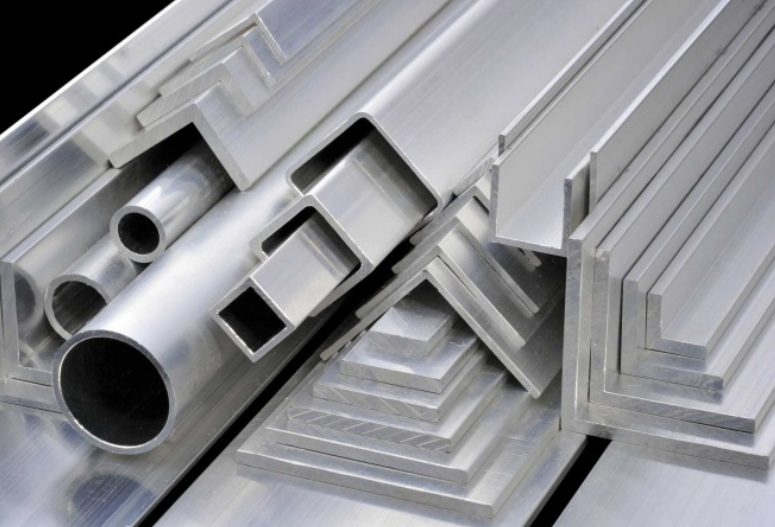

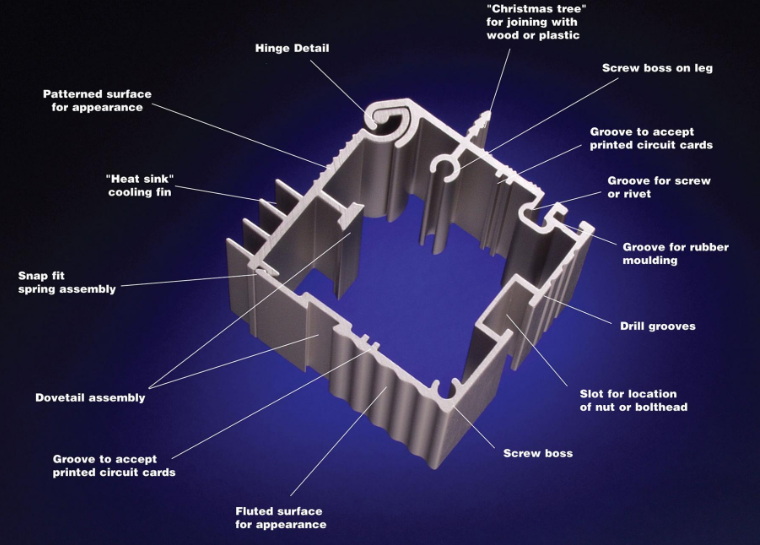

Before delving into the services provided, it's essential to understand the basics of aluminum extrusion. Aluminum extrusion is a process where aluminum alloy is forced through a die of a specific cross-sectional profile. The process is akin to squeezing toothpaste out of a tube, where the opening of the tube determines the shape of the toothpaste.

Key Advantages of Aluminum Extrusion:

- Versatility: Aluminum can be extruded into nearly any imaginable shape.

- Cost-Effectiveness: Tooling costs are relatively low compared to other shaping processes.

- Strength and Lightweight: Aluminum offers a high strength-to-weight ratio.

- Corrosion Resistance: Aluminum naturally resists corrosion.

- Recyclability: Aluminum is highly recyclable, making it an environmentally friendly option.

Core Services Offered by Aluminum Extruder Companies

Top "aluminum extruder companies" provide a broad spectrum of services to meet the diverse needs of their clientele. These services can be broadly categorized as follows:

- Design and Engineering Support

- Extrusion Manufacturing

- Fabrication Services

- Finishing Services

- Assembly and Packaging

- Supply Chain Management

Design and Engineering Support

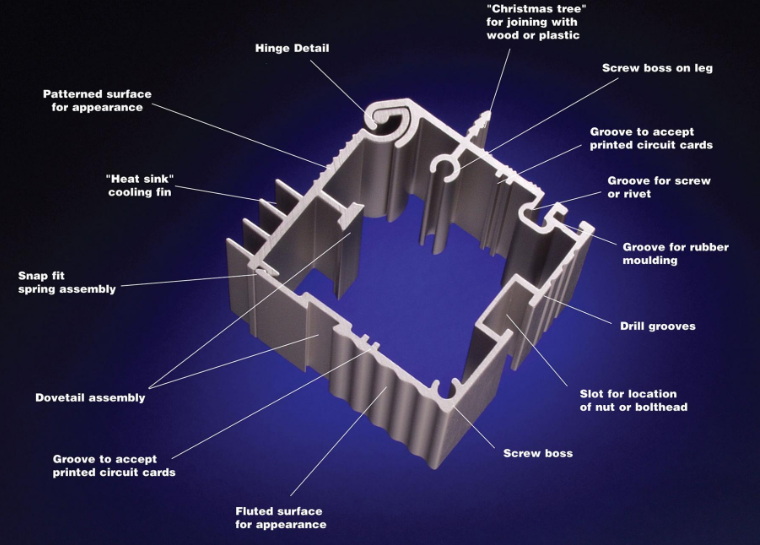

"Aluminum extruder companies" often provide design and engineering support to assist clients in developing the optimal extrusion profile for their application. This service is invaluable for clients who may not have in-house expertise in aluminum extrusion design.

Key Aspects of Design and Engineering Support:

- Design Consultation: Working with clients to understand their requirements and provide design recommendations.

- CAD/CAM Services: Utilizing Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software to create and refine extrusion designs.

- Prototyping: Creating prototypes to test the design and ensure it meets the required specifications.

- Die Design and Manufacturing: Designing and manufacturing the extrusion die, which is a critical component of the extrusion process.

Extrusion Manufacturing

The core service of any "aluminum extruder company" is, of course, the extrusion process itself. This involves taking raw aluminum billets and transforming them into custom profiles.

Key Considerations in Extrusion Manufacturing:

- Alloy Selection: Choosing the appropriate aluminum alloy based on the application's requirements.

- Extrusion Press Capabilities: Utilizing extrusion presses of various sizes and capacities to accommodate different profile dimensions.

- Tight Tolerance Control: Maintaining precise dimensional accuracy throughout the extrusion process.

- Quality Control: Implementing rigorous quality control measures to ensure the extrusions meet the required standards.

Fabrication Services

Extruded aluminum profiles often require additional fabrication to meet the final product specifications. *Aluminum extruder companies* offer a range of fabrication services to add value to the extrusion process.

Common Fabrication Services Include:

- Cutting: Precision cutting of extrusions to specific lengths.

- Machining: CNC machining to create complex features and tight tolerances.

- Drilling and Punching: Creating holes and openings in the extrusions.

- Bending and Forming: Shaping the extrusions to meet specific geometric requirements.

- Welding: Joining multiple extrusions or components together.

Finishing Services

Finishing services enhance the appearance, durability, and corrosion resistance of aluminum extrusions. *Aluminum extruder companies* offer a variety of finishing options to meet different aesthetic and functional needs.

Popular Finishing Services:

- Anodizing: An electrochemical process that creates a protective oxide layer on the aluminum surface.

- Powder Coating: Applying a decorative and protective powder coating to the extrusion.

- Painting: Applying liquid paint finishes to the extrusion.

- Brushing and Polishing: Creating a smooth and aesthetically pleasing surface finish.

- Etching: Using chemical etching to create textures or patterns on the aluminum surface.

Assembly and Packaging

Some "aluminum extruder companies" offer assembly and packaging services to provide clients with fully finished products ready for distribution or use.

Typical Assembly and Packaging Services:

- Component Assembly: Assembling multiple components, including extrusions, into a final product.

- Hardware Installation: Installing hardware such as screws, bolts, and fasteners.

- Custom Packaging: Providing custom packaging solutions to protect finished products during shipping and storage.

Supply Chain Management

Top "aluminum extruder companies" understand the importance of efficient supply chain management. They offer services to streamline the process from raw material sourcing to final product delivery.

Key Aspects of Supply Chain Management:

- Material Sourcing: Sourcing high-quality aluminum billets from reliable suppliers.

- Inventory Management: Maintaining adequate inventory levels to meet customer demand.

- Logistics and Shipping: Providing efficient logistics and shipping services to ensure timely delivery.

Value-Added Services

In addition to core services, "aluminum extruder companies" often provide a range of value-added services to differentiate themselves and better serve their clients.

Examples of Value-Added Services:

- Rapid Prototyping: Expedited prototyping services to quickly validate designs.

- Just-in-Time (JIT) Delivery: Delivering products on a JIT basis to minimize inventory costs.

- Vendor-Managed Inventory (VMI): Managing inventory levels on behalf of clients.

- Technical Support: Providing technical expertise and support throughout the product lifecycle.

Emerging Trends in Aluminum Extrusion

The aluminum extrusion industry continues evolving with advancements in technology that enhance efficiency, sustainability, and product quality. Some notable trends include:

Automation and Robotics

The integration of automated systems in extrusion plants increases production efficiency by handling repetitive tasks such as billet loading and quality inspection. This reduces human error while improving overall product quality.

Artificial Intelligence (AI)

AI is revolutionizing the aluminum extrusion industry by optimizing processes like predictive maintenance and die design. AI algorithms analyze real-time data from machinery, enabling immediate adjustments to ensure that each profile meets exact specifications.

Smart Manufacturing

Smart manufacturing involves using IoT (Internet of Things) devices and data analytics to monitor production processes comprehensively. By collecting real-time data, manufacturers can identify inefficiencies and make informed decisions that improve productivity.

3D Printing Integration

The fusion of aluminum extrusion with 3D printing technology allows for rapid prototyping of intricate designs. This synergy enables manufacturers to produce complex geometries that traditional methods cannot achieve.

Advanced Die Design

Recent advancements have made it possible to create more complex die shapes that enhance cooling systems, improving die lifespan. Computer-Aided Design (CAD) software enables designers to create intricate die shapes that enhance cooling systems' performance.

Industries Served by Aluminum Extruder Companies

The versatility of aluminum extrusion makes it suitable for various industries. "Aluminum extruder companies" serve diverse markets, including:

- Automotive: Providing lightweight components for vehicles that improve fuel efficiency without sacrificing safety or performance.

- Construction: Supplying architectural extrusions for buildings, including window frames, curtain walls, roofing systems, etc., which require durability combined with aesthetic appeal.

- Electronics: Manufacturing heat sinks for electronic devices ensuring efficient heat dissipation which prolongs device life while maintaining performance standards.

- Transportation: Producing components for trains, buses, trucks, etc., where weight reduction contributes directly towards fuel savings.

- Renewable Energy: Creating structural components for solar panels or wind turbines designed specifically for optimal performance under various environmental conditions.

- Aerospace: Providing high-strength lightweight components essential for aircraft performance while adhering strictly to safety regulations.

- Consumer Goods: Manufacturing components used in furniture or appliances designed specifically with consumer preferences in mind regarding aesthetics as well as functionality.

Choosing the Right Aluminum Extruder Company

Selecting an appropriate "aluminum extruder company" is crucial for ensuring project success. Consider these factors when making your choice:

- Experience & Expertise: Look for companies with extensive experience in aluminum extrusion across multiple industries ensuring they understand your specific needs thoroughly.

- Capabilities: Ensure they offer all necessary services from design through fabrication up until delivery; this ensures seamless communication throughout every stage reducing potential delays significantly.

- Quality Certifications: Verify certifications such as ISO 9001:2015 which indicate adherence towards rigorous quality standards across all operations performed within their facilities guaranteeing consistency throughout production runs regardless if large-scale or small batch orders are required by clients alike!

- Customer Service: Choose those who prioritize excellent customer service providing timely responses addressing any concerns raised promptly maintaining transparency throughout every interaction fostering trust between both parties involved!

- Price Competitiveness: Obtain quotes from multiple suppliers ensuring competitive pricing without compromising quality; this helps manage budgets effectively while still achieving desired outcomes!

Conclusion

In conclusion, "aluminum extruder companies" offer a comprehensive suite of services that extend far beyond merely shaping aluminum. From design support through fabrication processes all way until final assembly & packaging these organizations provide end-to-end solutions tailored specifically towards client needs across numerous industries! By understanding these diverse offerings alongside emerging trends within this dynamic field one can make informed decisions when selecting partners who will contribute positively towards achieving project goals successfully!

Frequently Asked Questions (FAQs)

1. What are common aluminum alloys used in extrusion?

Common aluminum alloys used in extrusion include 6061, 6063, and 6005A. These alloys offer a good balance between strength, corrosion resistance, and ease of fabrication suitable for various applications across multiple sectors!

2. What is the difference between direct & indirect extrusion?

In direct extrusion processes; billets are pushed through dies via hydraulic rams whereas indirect methods involve pushing dies through stationary billets resulting in different characteristics concerning material flow behavior leading towards unique applications based upon desired outcomes!

3. How does anodizing improve aluminum extrusions?

Anodizing creates protective oxide layers enhancing corrosion resistance while also improving durability & aesthetic appeal making products more visually appealing thereby increasing marketability!

4. What are typical lead times for aluminum extrusion projects?

Lead times vary depending on project complexity & material availability; simple projects may take weeks whereas complex ones could span several months due diligence should be exercised when planning timelines accordingly!

5. Can aluminum extrusions be recycled?

Yes! Aluminum is highly recyclable requiring only about 5% energy needed compared against producing new materials making it environmentally friendly choice promoting sustainability initiatives within manufacturing sectors globally!

Citations:

[1] https://eagle-aluminum.com

[2] https://profileprecisionextrusions.com/the-evolution-of-aluminum-extrusions-emerging-trends-and-technologies/

[3] https://www.atieuno.com/aluminium-extrusion-case-studies/

[4] https://www.pyramids-tw.com/aluminum-extrusion-service.html

[5] https://www.alcircle.com/news/tech-trends-driving-the-aluminium-extrusion-industry-111131

[6] https://dajcor.com/learning-centre/case-studies

[7] https://www.hydro.com/profiles/aluminum-extrusion-companies

[8] https://www.yjing-extrusion.com/what-are-the-latest-trends-in-aluminum-extrusion-design.html

[9] https://www.supergas.com/for-industrial/case-studies/aluminium-extrusion-application

[10] https://dajcor.com/extrusion

[11] https://www.metalsminingreview.com/cxoinsight/exploring-emerging-trends-and-technologies-in-aluminum-extrusions-nwid-1012.html

[12] https://www.10in6.com/case-studies/aluminum-extrusion-plant-case-study/

[13] https://www.3erp.com/services/aluminum-extrusion/

[14] https://gloriaaluminium.com/blog/the-future-of-the-aluminum-extrusion-industry-trends-and-growth/

[15] https://productidnetwork.com/aluminum-extruder-company-case-study/

[16] https://www.sourcingallies.com/blog/aluminum-extrusion-companies

[17] https://americandouglasmetals.com/2023/12/20/global-aluminum-extrusion-market-2023-2030-growth-trends-key-players-and-industry-insights/

[18] https://www.goldapple-alu.com/case-studies-success-stories-from-top-aluminum-extrusion-suppliers.html

[19] https://aluminum-extrusions.net/more-aluminum-extrusions-manufacturers-listings/

[20] https://www.linkedin.com/pulse/trends-global-aluminum-alloy-extrusion-industry-focus-seamless-ua2fe