Content Menu

● Factors Affecting the Price of PE Tube Extrusion Equipment

>> 1. Production Capacity

>> 2. Automation Level

>> 3. Customization Options

>> 4. Brand and Supplier

● Latest Advancements in PE Tube Extrusion Technology

● Cost-Saving Tips for PE Tube Extrusion

● Environmental Impact of PE Tube Extrusion

● Future Trends in PE Tube Extrusion Equipment

● Case Studies: Success Stories with PE Tube Extrusion Equipment

● Conclusion

● FAQ

>> 1. What is the typical price range for PE tube extrusion equipment?

>> 2. What factors influence the cost of PE tube extrusion machines?

>> 3. Are there affordable options for small-scale operations?

>> 4. How can I ensure quality while purchasing cheap equipment?

>> 5. What industries use PE tube extrusion equipment?

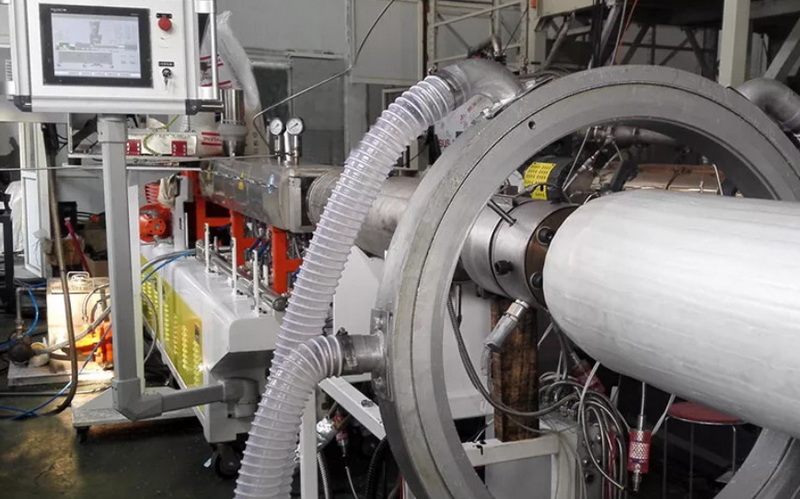

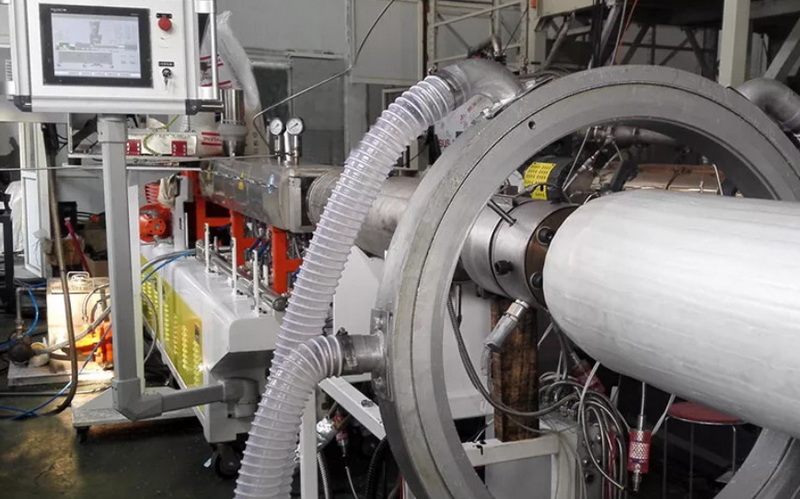

PE tube extrusion equipment is a cornerstone of modern manufacturing, enabling the production of polyethylene (PE) pipes and tubes for various industries. These pipes are widely used in water supply systems, gas transmission lines, agricultural irrigation, and construction. However, the price of such equipment can vary significantly based on factors like production capacity, automation level, and customization options. This article provides a comprehensive guide to understanding the pricing of PE tube extrusion equipment, exploring advancements in technology, cost-saving strategies, and future trends. By the end, you'll have a clear understanding of how to find "cheap PE tube extrusion equipment prices" without compromising on quality.

Factors Affecting the Price of PE Tube Extrusion Equipment

1. Production Capacity

The production capacity of a machine is one of the most significant factors influencing its price. Machines with higher output rates or the ability to produce larger diameter pipes are generally more expensive due to their advanced components and higher power requirements.

| Machine Model | Diameter Range (mm) | Output (kg/h) | Price Range ($) |

| PEG-110 | 20-63 | 120-220 | 17,000-19,000 |

| PEG-800 | 400-800 | 800-1400 | 21,000+ |

| PEG-1600 | 800-1600 | 800-1400 | 25,000+ |

For small-scale operations, machines with lower capacities are more affordable and sufficient for limited production needs.

2. Automation Level

Automation plays a crucial role in determining the cost of PE tube extrusion equipment:

- Manual Systems: These are the most affordable but require significant labor input.

- Semi-Automatic Systems: Offer a balance between cost and efficiency.

- Fully Automatic Systems: These are the most expensive but provide high precision and efficiency through features like PLC controls and automated cutting.

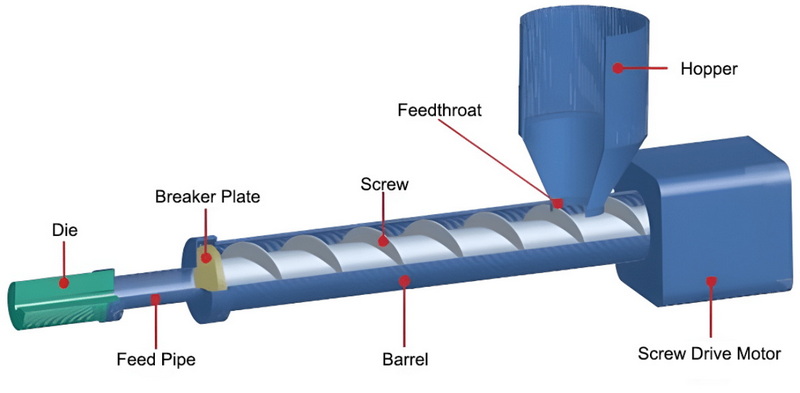

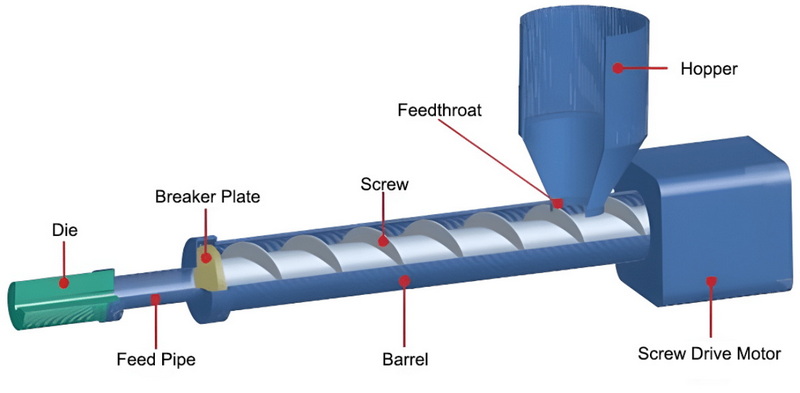

3. Customization Options

Customization can significantly impact pricing. For example:

- Specialized screw designs for better material processing.

- Advanced cooling systems for uniform pipe dimensions.

- Custom pipe diameter ranges tailored to specific industries.

These features enhance performance but come at an additional cost.

4. Brand and Supplier

Different brands and suppliers offer varying price points based on their reputation, technology, and after-sales services. Trusted platforms like Alibaba and IndiaMART provide competitive pricing for *cheap PE tube extrusion equipment* while maintaining quality standards.

Latest Advancements in PE Tube Extrusion Technology

Recent innovations in PE tube extrusion technology have made these machines more efficient and versatile:

1. Energy-Efficient Designs: Modern machines consume less energy while maintaining high output rates.

2. Smart Automation: Integration of AI and IoT enables real-time monitoring and optimization.

3. Improved Material Compatibility: New screw designs allow for better processing of recycled materials, reducing waste.

These advancements not only improve production efficiency but also contribute to cost savings in the long run.

Cost-Saving Tips for PE Tube Extrusion

If you're looking for *cheap PE tube extrusion equipment prices*, consider these strategies:

1. Bulk Purchasing: Suppliers often offer discounts for bulk orders.

2. Refurbished Equipment: Second-hand machines can be a cost-effective option if sourced from reliable vendors.

3. Energy-Efficient Models: Investing in energy-efficient equipment reduces operational costs over time.

4. Government Subsidies: Some regions offer subsidies for adopting eco-friendly manufacturing practices.

By implementing these tips, businesses can significantly reduce their initial investment without compromising on quality.

Environmental Impact of PE Tube Extrusion

The environmental impact of PE tube extrusion is a growing concern in the industry. Manufacturers are adopting sustainable practices such as:

1. Recycling scrap materials during production.

2. Using energy-efficient machinery to reduce carbon footprints.

3. Developing biodegradable or eco-friendly pipe materials.

These efforts not only benefit the environment but also align with global sustainability goals, making them an essential consideration for modern businesses.

Future Trends in PE Tube Extrusion Equipment

The future of PE tube extrusion equipment looks promising with several emerging trends:

1. Increased Automation: AI-driven systems will further enhance precision and reduce labor costs.

2. Eco-Friendly Materials: Expect more focus on biodegradable polymers and recycled materials.

3. Compact Designs: Space-saving machines with modular components will become popular.

4. Smart Manufacturing: IoT-enabled machines will allow real-time monitoring and predictive maintenance.

Staying ahead of these trends can help businesses remain competitive while meeting evolving market demands.

Case Studies: Success Stories with PE Tube Extrusion Equipment

Several companies have achieved remarkable success by adopting advanced PE tube extrusion machines:

- A water supply company reduced production costs by 15% by switching to energy-efficient models.

- An agricultural firm increased output by 25% after upgrading to a fully automated system.

- A construction business improved product quality by using customized screw designs tailored to their specific needs.

These examples highlight the potential benefits of investing in modern extrusion technology.

Conclusion

PE tube extrusion equipment is an integral part of many industries, offering solutions for producing high-quality polyethylene pipes at varying price points. By understanding factors like production capacity, automation level, and customization options, businesses can make informed decisions when purchasing machinery. Recent advancements in technology and sustainable practices further enhance the value proposition of these machines.

Whether you're looking for cheap PE tube extrusion equipment prices or planning to invest in cutting-edge technology, this guide provides all the information you need to make a smart purchase decision.

FAQ

1. What is the typical price range for PE tube extrusion equipment?

Prices range from $5,000 for small-scale machines to over $25,000 for high-capacity models with advanced features.

2. What factors influence the cost of PE tube extrusion machines?

Key factors include production capacity, automation level, customization options (e.g., screw design), and brand reputation.

3. Are there affordable options for small-scale operations?

Yes! Small-scale machines start at around $5,000-$10,000 on platforms like Alibaba or IndiaMART.

4. How can I ensure quality while purchasing cheap equipment?

Look for verified suppliers offering warranties and after-sales services. Compare specifications to ensure the machine meets your requirements.

5. What industries use PE tube extrusion equipment?

Industries include water supply systems, gas transmission lines, agriculture irrigation systems, construction drainage systems, and more.