Content Menu

● Understanding Life Cycle Assessment (LCA)

● The Importance of LCA in Steel Production

● Innovations Driven by LCA

● Challenges in Implementing LCA

● Case Studies: Successful Applications of LCA in Steel

● Future Trends in Steel Industry Innovation Through LCA

● Conclusion

● FAQ

>> 1. What is Life Cycle Assessment (LCA)?

>> 2. How does LCA benefit the steel industry?

>> 3. What are some challenges faced when implementing LCA?

>> 4. Can you give an example of innovation driven by LCA?

>> 5. How does LCA contribute to circular economy practices?

● Citations:

The steel industry is a cornerstone of modern infrastructure and manufacturing, yet it is also one of the largest contributors to global greenhouse gas emissions. As the world shifts towards sustainability, the role of Life Cycle Assessment (LCA) in driving innovation within the steel sector has become increasingly critical. This article delves into how LCA can enhance sustainability practices, improve efficiency, and foster innovation in steel production and extrusion.

Understanding Life Cycle Assessment (LCA)

Life Cycle Assessment is a systematic process used to evaluate the environmental impacts associated with all stages of a product's life, from raw material extraction through production, use, and disposal. The LCA process typically includes four main phases:

- Goal and Scope Definition: Establishing the purpose of the assessment and determining the boundaries.

- Life Cycle Inventory (LCI): Collecting data on energy, materials, and emissions for each stage of the product's life cycle.

- Life Cycle Impact Assessment (LCIA): Evaluating the potential environmental impacts based on the inventory data.

- Interpretation: Analyzing results to inform decision-making and identify opportunities for improvement.

This comprehensive approach allows stakeholders to understand the environmental footprint of steel products and make informed decisions that promote sustainability.

The Importance of LCA in Steel Production

The steel industry is responsible for approximately 7-9% of global carbon dioxide emissions. Implementing LCA helps identify hotspots within the production process where emissions can be reduced. For instance:

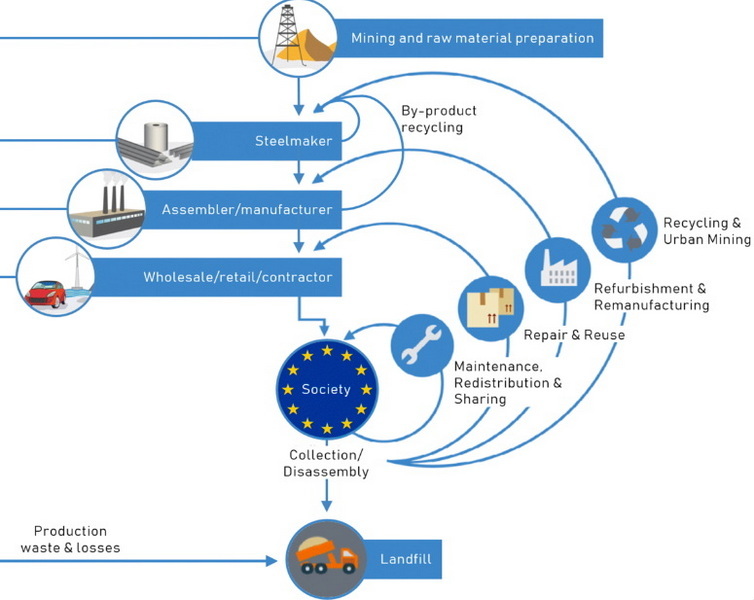

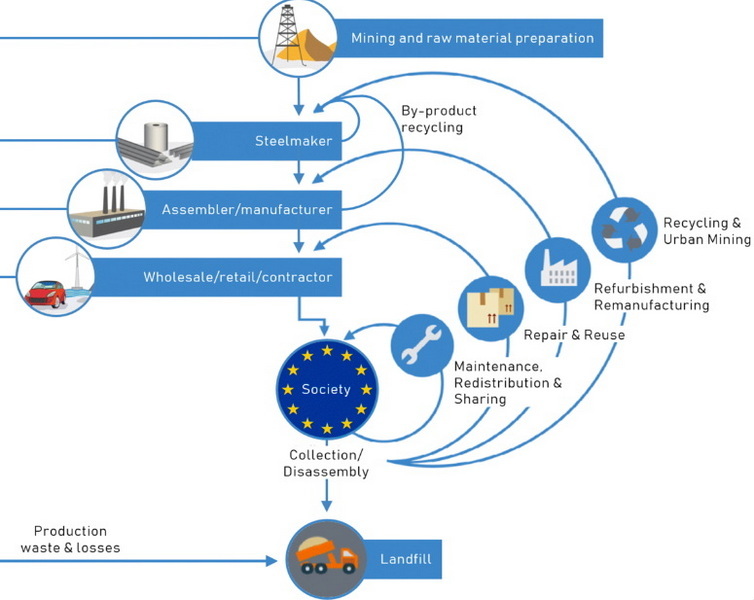

- Resource Extraction: LCA evaluates the environmental impact of mining iron ore and other raw materials, encouraging practices that minimize resource depletion.

- Manufacturing Processes: By analyzing different production methods, such as traditional blast furnaces versus electric arc furnaces (EAF), LCA can highlight more energy-efficient options.

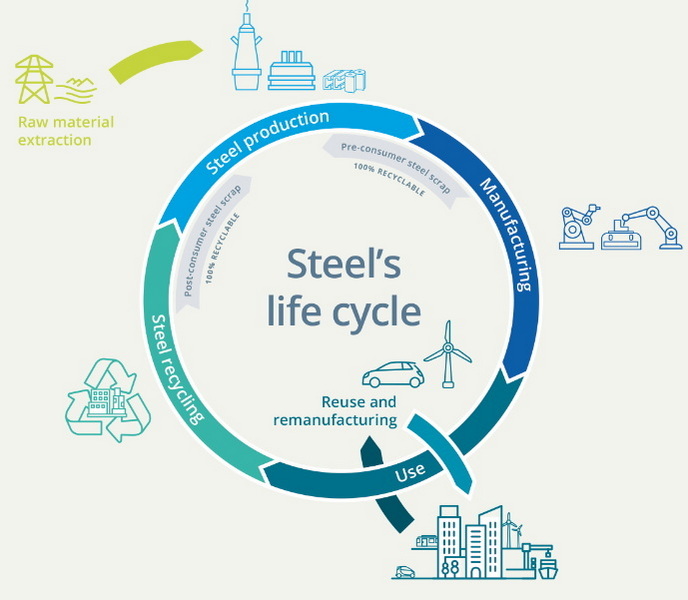

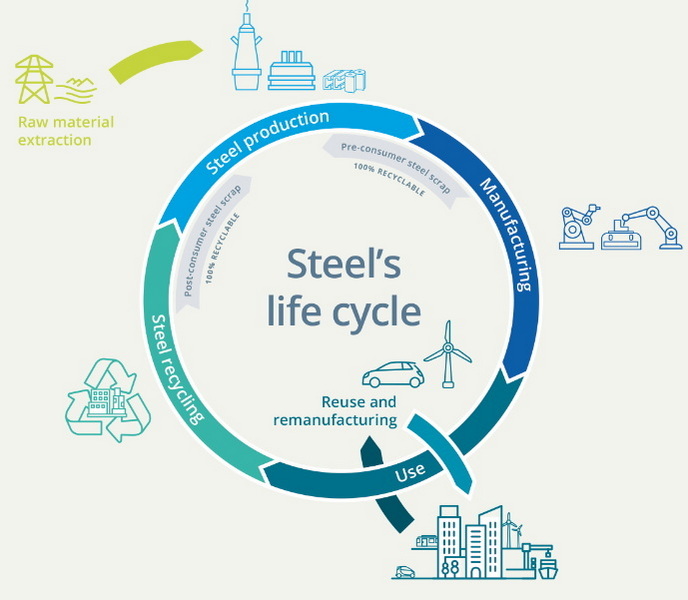

- End-of-Life Management: Understanding how steel products can be recycled or reused at the end of their life cycle is crucial for reducing waste and conserving resources.

Innovations Driven by LCA

LCA not only identifies areas for improvement but also drives innovation within the steel sector. Some notable innovations include:

1. High-Strength Steel Development: Advances in metallurgy have led to the creation of high-strength steel grades that reduce weight while maintaining structural integrity. This innovation contributes to lighter vehicles, which improves fuel efficiency and reduces emissions during use.

2. Hydrogen-Based Steelmaking: Projects like HYBRIT in Sweden are exploring hydrogen as a reducing agent instead of coal, aiming for near-zero emissions during steel production. This shift is made possible through insights gained from LCA studies that emphasize the importance of reducing carbon footprints.

3. Circular Economy Practices: LCA promotes a circular economy by emphasizing recycling and reusing materials. The steel industry has responded by increasing its reliance on scrap metal, with over 30% of global steel production now derived from recycled materials.

Challenges in Implementing LCA

Despite its benefits, implementing LCA in the steel industry faces several challenges:

- Data Availability: Accurate LCA requires comprehensive data across all life cycle stages. Gathering this data can be resource-intensive.

- Complexity of Processes: The diverse range of steel products and their manufacturing processes complicates LCA efforts, as each product may have a unique environmental profile.

- Stakeholder Engagement: Engaging all stakeholders—from raw material suppliers to end-users—is essential for effective LCA implementation but can be difficult to coordinate.

Case Studies: Successful Applications of LCA in Steel

Several companies have successfully integrated LCA into their operations:

- ArcelorMittal: This leading steel producer uses LCA to assess the environmental impact of its products, ensuring compliance with regulations while promoting transparency with customers about their products' sustainability credentials.

ArcelorMittal's Sustainable Practices

- Tata Steel: Tata has employed LCA to evaluate its manufacturing processes and identify opportunities for energy savings. The company has implemented various initiatives based on LCA findings, such as optimizing logistics to reduce transportation emissions.

Future Trends in Steel Industry Innovation Through LCA

Looking ahead, several trends are likely to shape the future of innovation in the steel industry through LCA:

1. Increased Automation and Digitalization: The integration of digital technologies into manufacturing processes will facilitate more accurate data collection for LCAs and enable real-time monitoring of environmental impacts.

2. Enhanced Collaboration Across Supply Chains: As sustainability becomes a priority across industries, collaboration among stakeholders will be crucial for sharing best practices and improving overall life cycle performance.

3. Regulatory Pressure for Transparency: Governments are increasingly mandating transparency regarding environmental impacts, making LCA an essential tool for compliance and competitive advantage.

Conclusion

Life Cycle Assessment plays a pivotal role in driving innovation within the steel industry by providing a comprehensive understanding of environmental impacts throughout a product's life cycle. By identifying opportunities for improvement, promoting sustainable practices, and fostering collaboration among stakeholders, LCA is essential for transforming the steel sector into a more sustainable industry. As technology advances and regulatory pressures increase, embracing LCA will be vital for any company aiming to lead in sustainability while maintaining competitiveness in a rapidly evolving market.

FAQ

1. What is Life Cycle Assessment (LCA)?

LCA is a systematic method used to evaluate the environmental impacts associated with all stages of a product's life cycle—from raw material extraction to disposal.

2. How does LCA benefit the steel industry?

LCA helps identify areas where emissions can be reduced, promotes sustainable practices like recycling, and drives innovation in production methods.

3. What are some challenges faced when implementing LCA?

Challenges include data availability, complexity due to diverse manufacturing processes, and engaging all stakeholders effectively.

4. Can you give an example of innovation driven by LCA?

One example is hydrogen-based steelmaking initiatives like HYBRIT, which aim to reduce carbon emissions significantly during production.

5. How does LCA contribute to circular economy practices?

LCA emphasizes recycling and reusing materials at end-of-life stages, encouraging practices that minimize waste and conserve resources within the steel industry.

Citations:

[1] https://www.nord-lock.com/learnings/knowledge/2020/green-steel/

[2] https://nexus.openlca.org/ws/files/21347

[3] https://worldsteel.org/steel-topics/life-cycle-thinking/lca-eco-profiles-2022/global-seamless-pipe-construction/

[4] https://www.youtube.com/watch?v=5B24PeFWvrU

[5] https://worldsteel.org/steel-topics/life-cycle-thinking/life-cycle-assessment-in-the-steel-industry/

[6] https://www.ispatguru.com/life-cycle-assessment-and-steel-sustainability/

[7] https://www.youtube.com/watch?v=ig1OoRVtEZk

[8] https://www.youtube.com/watch?v=pJ8swFDSv0k

[9] https://www.steel.org/sustainability/life-cycle/

[10] https://www.researchgate.net/publication/286758519_Environmental_Comparison_between_a_Hot_Extrusion_Process_and_Conventional_Machining_Processes_through_a_Life_Cycle_Assessment_Approach

[11] https://www.mdpi.com/2071-1050/14/21/14131

[12] https://sites.gatech.edu/i2ce/circular-building/

[13] https://www.sciencedirect.com/science/article/pii/S0959652624029871

[14] https://eoxs.com/new_blog/the-role-of-lifecycle-analysis-in-reducing-steel-industry-emissions/

[15] https://automotive.arcelormittal.com/news_and_stories/videos/SteelYourEnvironment

[16] https://www.ptonline.com/articles/how-life-cycle-assessment-(lca)-measures-a-manufacturers-carbon-footprint-and-environmental-impact

[17] https://www.facebook.com/worldautosteel/videos/life-cycle-assessment-lca-presents-the-best-way-to-determine-the-complete-enviro/8901787223275558/

[18] https://www.worldautosteel.org/life-cycle-assessment-sees-the-big-picture-video/

[19] https://www.facebook.com/worldsteel/videos/steelie-awards-2021-winner-excellence-in-life-cycle-assessment/256293843133014/

[20] https://www.youtube.com/watch?v=XwRqgupTlJ0

[21] https://onlinelibrary.wiley.com/doi/10.1155/2020/8863941

[22] https://www.worldautosteel.org/life-cycle-thinking/lca-videos/video-dr-roland-geyer-on-life-cycle-assessment/

[23] https://eplca.jrc.ec.europa.eu/permalink/PLASTIC_LCI/Plastics%20LCA_Report%20I_Updated%20Draft%20Method_2020.06.03.pdf

[24] https://worldsteel.org/steel-topics/life-cycle-thinking/life-cycle-assessment-in-the-steel-industry/