Content Menu

● Understanding Aluminum Extrusion and Vacuum Pressing

● Key Materials for Holding Film in Vacuum Presses

● Factors Influencing Material Selection

● Applications of Vacuum Pressing in Aluminum Extrusion

● Conclusion

● FAQ

>> 1. What types of films can be used in aluminum extrusion vacuum presses?

>> 2. How does temperature affect material selection for vacuum pressing?

>> 3. What role do breather fabrics play in vacuum pressing?

>> 4. Can sealant tapes be reused?

>> 5. How do I determine which material is best for my specific application?

● Citations:

In the world of aluminum extrusion, the vacuum press is a crucial tool used to ensure that films adhere properly to the aluminum surfaces during the manufacturing process. The choice of materials for holding the film in place is vital for achieving optimal results. This article will explore the best materials for holding film in aluminum extrusion vacuum presses, detailing their properties, applications, and benefits.

Understanding Aluminum Extrusion and Vacuum Pressing

Aluminum extrusion is a manufacturing process that involves forcing heated aluminum alloy through a die to create specific shapes. This process can produce a wide variety of profiles, from simple bars to complex designs used in various industries such as construction, automotive, and aerospace.

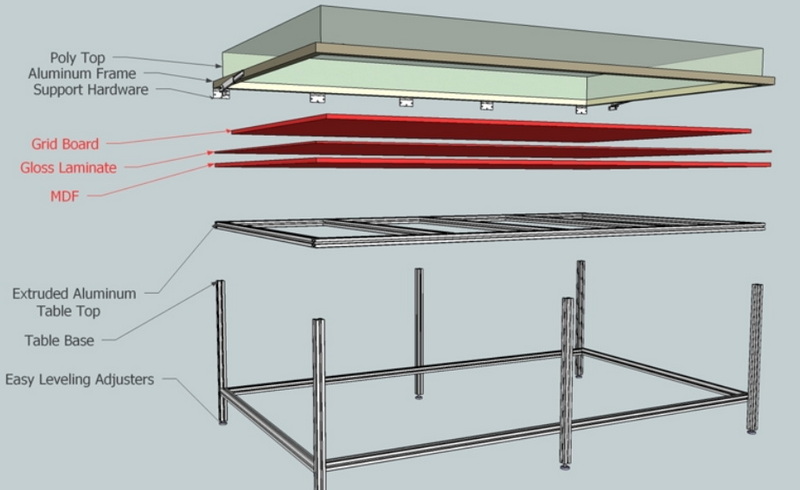

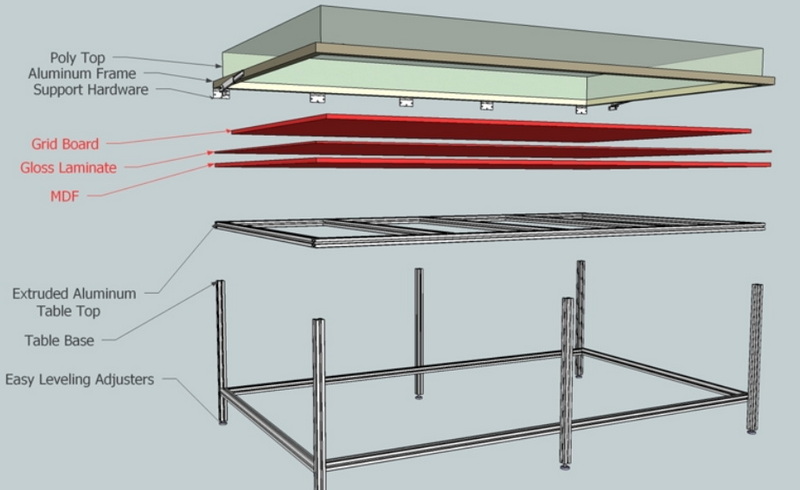

The vacuum press plays a significant role in this process by applying uniform pressure to ensure that films or coatings are tightly adhered to the aluminum surface. This is especially important when dealing with protective films or decorative coatings that enhance the aesthetic and functional properties of the extruded aluminum.

Key Materials for Holding Film in Vacuum Presses

The following materials are commonly used for holding film in aluminum extrusion vacuum presses:

1. Polyester Film

Polyester films are widely used due to their excellent mechanical properties and resistance to temperature and chemicals. They provide a strong barrier against moisture and contaminants, making them ideal for protecting aluminum surfaces during extrusion.

- Advantages:

- High tensile strength

- Excellent dimensional stability

- Good chemical resistance

- Available in various thicknesses

2. Nylon Films

Nylon films are known for their high strength and flexibility. They can withstand high temperatures and provide excellent puncture resistance, making them suitable for demanding applications.

- Advantages:

- Superior strength-to-weight ratio

- High-temperature tolerance

- Excellent abrasion resistance

- Good barrier properties

3. Release Films

Release films are designed to prevent sticking between the film and the aluminum surface. They are often used in conjunction with other materials to facilitate easy removal after processing.

- Advantages:

- Low surface energy reduces adhesion

- Easy to remove without leaving residues

- Available with various coatings for enhanced performance

4. Breather Fabrics

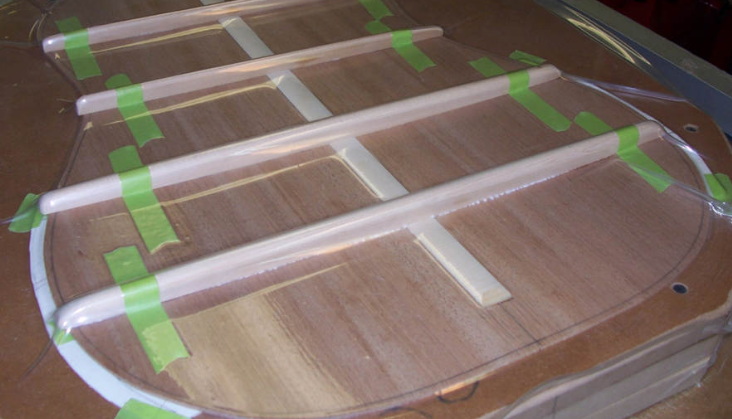

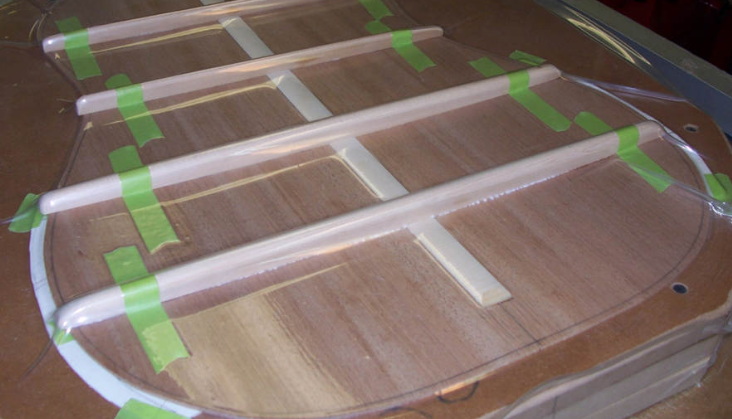

Breather fabrics are porous materials that allow air to escape during the vacuum process while providing support to the film. They help maintain even pressure across the surface during processing.

- Advantages:

- Promotes uniform vacuum distribution

- Reduces the risk of air pockets

- Enhances overall adhesion of films

5. Sealant Tapes

Sealant tapes are used to secure the edges of films and prevent leaks during the vacuum process. They are essential for maintaining a tight seal around the edges of the film.

- Advantages:

- Easy application and removal

- Provides a strong seal against air leaks

- Available in various widths and thicknesses

Factors Influencing Material Selection

When selecting materials for holding film in an aluminum extrusion vacuum press, several factors should be considered:

- Temperature Resistance: The materials must withstand the high temperatures involved in the extrusion process without degrading.

- Chemical Compatibility: The chosen materials should not react with any chemicals used during processing, including lubricants or coatings.

- Mechanical Properties: High tensile strength and flexibility are essential to ensure that the materials can withstand pressure without tearing or deforming.

- Cost-Effectiveness: While performance is critical, cost considerations also play a significant role in material selection.

Applications of Vacuum Pressing in Aluminum Extrusion

Vacuum pressing is utilized in various applications within aluminum extrusion, including:

- Protective Coatings: Applying protective films that shield aluminum from scratches, corrosion, and other environmental factors.

- Decorative Finishes: Using decorative films that enhance the visual appeal of extruded products.

- Adhesive Bonding: Facilitating adhesive bonding processes where uniform pressure is required for optimal adhesion.

Conclusion

Selecting the right materials for holding film in aluminum extrusion vacuum presses is crucial for ensuring high-quality finishes and product durability. Polyester films, nylon films, release films, breather fabrics, and sealant tapes each offer unique advantages tailored to specific applications within the extrusion process. By understanding these materials' properties and how they interact with aluminum, manufacturers can optimize their production processes and achieve superior results.

FAQ

1. What types of films can be used in aluminum extrusion vacuum presses?

Various types of films can be used, including polyester films, nylon films, release films, and protective coatings designed specifically for high-temperature applications.

2. How does temperature affect material selection for vacuum pressing?

Materials must withstand high temperatures without degrading or losing their adhesive properties; therefore, selecting heat-resistant options is essential.

3. What role do breather fabrics play in vacuum pressing?

Breather fabrics allow air to escape during the vacuum process while providing support to ensure even pressure distribution across the film.

4. Can sealant tapes be reused?

Sealant tapes are typically designed for single-use applications; however, some high-quality tapes may allow limited reuse depending on their adhesive properties.

5. How do I determine which material is best for my specific application?

Consider factors such as temperature resistance, chemical compatibility, mechanical properties, and cost-effectiveness when selecting materials for your specific application.

Citations:

[1] https://na-prod-aventri-files.s3.amazonaws.com/html_file_uploads/6f00017acb9f4045084e0fad1ea08ce6_copelandpaper.pdf?AWSAccessKeyId=AKIA3OQUANZMGCIZWZ6F&Expires=1712551361&Signature=iLTiGBJaSYVZw4n4%2FqAFFQlRXio%3D&response-content-disposition=inline%3Bfilename%3D%22copeland+paper.pdf%22&response-content-type=application%2Fpdf

[2] https://www.uscomposites.com/vacuum.html

[3] https://www.youtube.com/watch?v=8dNCQGarMxU

[4] https://www.youtube.com/watch?v=iiGlq7408ME

[5] https://waykenrm.com/blogs/aluminum-extrusion/

[6] https://www.rtprototype.com/a-guide-of-aluminum-extrusion/

[7] https://www.machine4aluminium.com/portfolio/aluminum-profile-protective-film-application/

[8] https://bonnellaluminum.com/tech-info-resources/aluminum-extrusion-process/

[9] https://www.lubrizol.com/-/media/Lubrizol/Health/Literature/LSP-Extrusion-Guide.pdf

[10] https://compraco.com.br/en/blogs/industria/extrusao-de-aluminio-101-um-guia-abrangente-para-o-processo

[11] https://www.vacfurnace.com/technology-frontiers/aluminum-extrusion-die-vacuum-heat-treatment/

[12] https://community.carbide3d.com/t/filling-aluminum-extrusions/67952

[13] http://aluminum-solution.com/basic-knowledge-of-aluminum.html

[14] https://www.tdpri.com/threads/budget-vacuum-press.899547/

[15] https://www.uniqueextrusions.com/aluminum-extrusion-faq/

[16] https://www.thegrumble.com/threads/best-adhesive-for-vacuum-press.84837/

[17] https://www.dynisco.com/userfiles/files/27429_Legacy_Txt.pdf

[18] https://www.lightmetalage.com/resources/patents/aluminum-extrusion-processing-and-applications/

[19] http://aluminum-solution.com/aluminum-extrusion-press.html

[20] https://www.cnczone.com/forums/work-fixtures-hold-down-solutions/238358-vacuum-hold-fixtures-job-specific-parts-aluminum-new-post.html

[21] https://www.youtube.com/watch?v=Olytr4PEDPs

[22] https://macrodynepress.com/hydraulic-presses/extrusion-presses/

[23] https://www.youtube.com/watch?v=P8BWQBP4Vhk

[24] https://www.youtube.com/watch?v=qK4Se4-E5xA

[25] https://explorecomposites.com/articles/lamination/troubleshooting-vacuum-infusion/

[26] https://www.facebook.com/qualityvak/videos/vacuum-table-press-for-veneering-and-laminating/10155692921423527/

[27] https://www.azom.com/article.aspx?ArticleID=17798

[28] https://qualityvak.com/frame.html

[29] https://www.youtube.com/watch?v=joOVcf_Xy_8

[30] https://www.youtube.com/watch?v=fLXPG-IcxD4

[31] https://www.youtube.com/watch?v=IBlvL6MoXNI

[32] https://www.ryerson.com/metal-resources/metal-market-intelligence/5-questions-on-aluminum-extrusions

[33] https://www.joewoodworker.com/veneering/faq.htm

[34] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[35] https://www.minalex.com/2021/10/29/10-questions-ask-aluminum-extruder/

[36] https://aec.org/faqs

[37] https://www.easycomposites.co.uk/learning/hand-laminate-vacuum-bag-simple-part

[38] https://www.youtube.com/watch?v=IqkxyACWorI

[39] https://www.youtube.com/watch?v=ELgtjeJyFw8

[40] https://www.henryholsters.com/product/swiftpress/

[41] https://bonnellaluminum.com/tech-info-resources/aluminum-extrusion-process/