Content Menu

● Introduction

● Understanding T-Slot Aluminum Extrusions

● Key Benefits of T-Slot Aluminum Extrusions

>> Versatility in Design

>> Ease of Assembly

>> Lightweight and Durable

>> Cost-Effectiveness

● Applications of T-Slot Aluminum Extrusions

>> Automation and Robotics

>> Industrial Workstations

>> Display and Exhibition Stands

>> Machine Enclosures

>> Furniture Design

● Conclusion

● Frequently Asked Questions

>> 1. What are T-slot connectors, and how do they work?

>> 2. Can T-slot aluminum extrusions be used in outdoor applications?

>> 3. How do I determine the right size of T-slot aluminum extrusion for my project?

>> 4. Are T-slot aluminum extrusions customizable?

>> 5. What industries commonly use T-slot aluminum extrusions?

Introduction

In the realm of modern manufacturing and construction, aluminum extrusion has emerged as a pivotal technology, enabling the creation of lightweight yet robust structures. Among the various forms of aluminum extrusion, T-slot aluminum extrusions stand out due to their versatility and ease of assembly. T-slot connectors play a crucial role in maximizing the potential of these extrusions, allowing for custom designs that meet specific project requirements. This article delves into the significance of T-slot connectors in custom aluminum extrusions, exploring their benefits, applications, and the innovative solutions they provide.

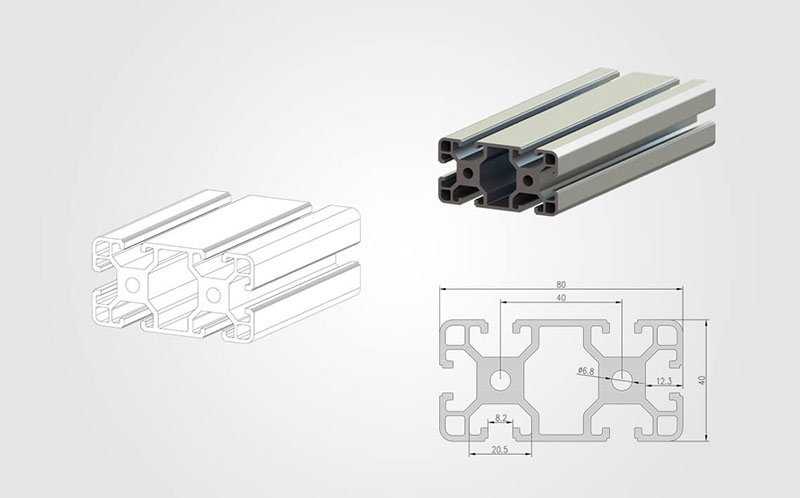

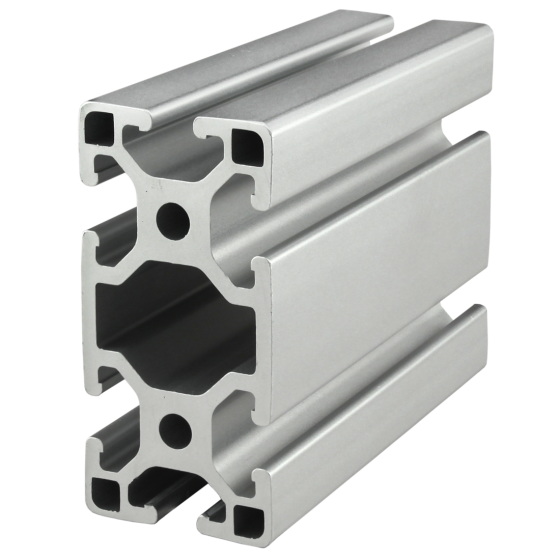

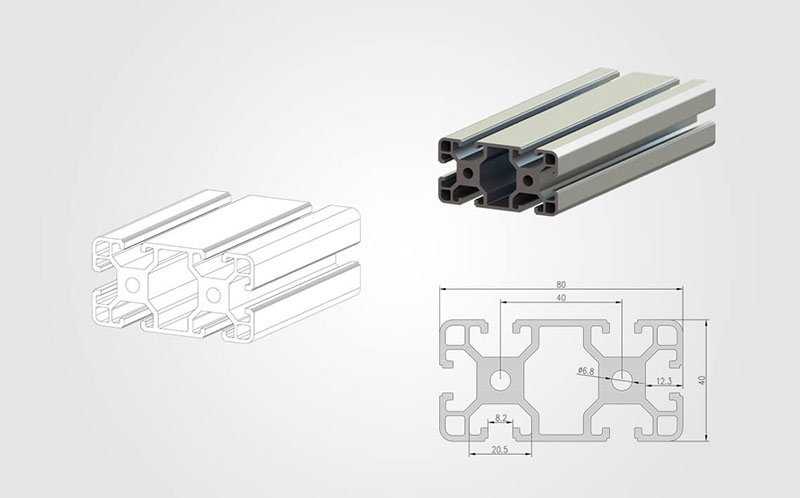

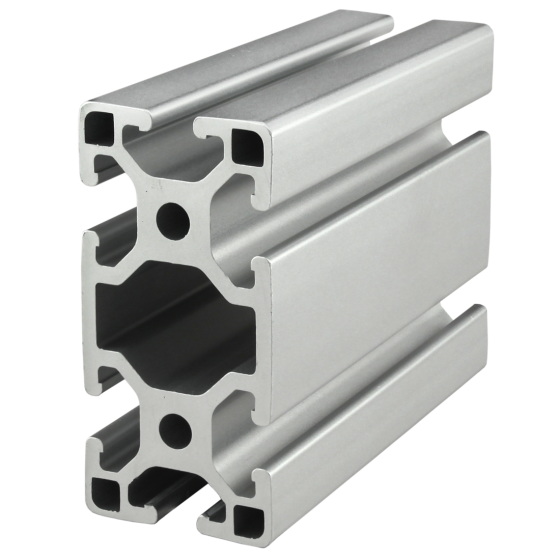

Understanding T-Slot Aluminum Extrusions

T-slot aluminum extrusions are profiles that feature a unique T-shaped groove along their length. This design allows for the easy attachment of various components, making it an ideal choice for modular construction. Unlike traditional aluminum extrusions, which may require welding or complex fastening methods, T-slot systems enable quick assembly and disassembly, facilitating flexibility in design and application.

The T-slot design not only enhances the structural integrity of the assembly but also provides a clean and professional appearance. This is particularly important in industries where aesthetics matter, such as in the production of display stands, workstations, and machinery enclosures.

Key Benefits of T-Slot Aluminum Extrusions

Versatility in Design

One of the most significant advantages of T-slot aluminum extrusions is their versatility. These profiles can be used in a wide range of applications, from simple frames to complex machinery. The ability to customize the length and configuration of the extrusions allows engineers and designers to create solutions tailored to their specific needs.

For instance, in the automation industry, T-slot aluminum extrusions are commonly used to build conveyor systems, robotic arms, and machine frames. The modular nature of these systems means that they can be easily reconfigured or expanded as project requirements change.

Ease of Assembly

T-slot connectors simplify the assembly process, making it accessible even to those without extensive technical expertise. The connectors are designed to fit seamlessly into the T-slots of the extrusions, allowing for quick and secure fastening. This ease of assembly reduces labor costs and minimizes the time required to complete projects.

Moreover, the ability to disassemble and reassemble structures without damaging the components is a significant advantage. This feature is particularly beneficial in environments where equipment needs to be frequently modified or relocated.

Lightweight and Durable

Aluminum is known for its lightweight properties, and when combined with the T-slot design, it results in structures that are not only easy to handle but also incredibly strong. The strength-to-weight ratio of aluminum makes it an ideal material for applications where weight is a concern, such as in aerospace and automotive industries.

Additionally, aluminum is resistant to corrosion, which enhances the durability of T-slot structures. This resistance ensures that the components maintain their integrity over time, even in challenging environments.

Cost-Effectiveness

Investing in T-slot aluminum extrusions can lead to significant cost savings in the long run. The modularity of these systems means that they can be reused and reconfigured for different projects, reducing the need for new materials. Furthermore, the ease of assembly minimizes labor costs, making T-slot systems a financially viable option for businesses.

The initial investment in T-slot connectors and extrusions is often offset by the savings realized through reduced assembly time and increased flexibility in design.

Applications of T-Slot Aluminum Extrusions

T-slot aluminum extrusions find applications across various industries, showcasing their adaptability and functionality. Here are some notable examples:

Automation and Robotics

In the automation sector, T-slot aluminum extrusions are widely used to construct frames for robotic systems, conveyor belts, and assembly lines. The ability to create custom configurations allows engineers to design systems that optimize workflow and efficiency.

Industrial Workstations

T-slot systems are ideal for building ergonomic workstations that can be tailored to the specific needs of workers. Adjustable heights, integrated storage solutions, and modular components make these workstations highly functional and user-friendly.

Display and Exhibition Stands

The clean lines and professional appearance of T-slot aluminum extrusions make them a popular choice for display stands at trade shows and exhibitions. The ability to create custom designs that can be easily assembled and disassembled is a significant advantage for businesses that frequently participate in events.

Machine Enclosures

T-slot aluminum extrusions are also used to create protective enclosures for machinery. These enclosures can be designed to provide easy access for maintenance while ensuring safety for operators. The lightweight nature of aluminum makes it easy to install and modify these enclosures as needed.

Furniture Design

In the realm of furniture design, T-slot aluminum extrusions are increasingly being used to create modern, minimalist pieces. The versatility of the extrusions allows designers to experiment with different shapes and configurations, resulting in unique and functional furniture solutions.

Conclusion

T-slot connectors are essential components in the world of custom aluminum extrusions, providing numerous benefits that enhance the functionality and versatility of these systems. Their ease of assembly, lightweight yet durable nature, and cost-effectiveness make them a preferred choice across various industries. As businesses continue to seek innovative solutions for their projects, T-slot aluminum extrusions and connectors will undoubtedly play a pivotal role in shaping the future of manufacturing and construction.

Frequently Asked Questions

1. What are T-slot connectors, and how do they work?

T-slot connectors are specialized fasteners designed to fit into the T-slots of aluminum extrusions. They allow for the secure attachment of various components, enabling quick assembly and disassembly of structures.

2. Can T-slot aluminum extrusions be used in outdoor applications?

Yes, T-slot aluminum extrusions are resistant to corrosion, making them suitable for outdoor applications. However, it is essential to consider environmental factors and choose appropriate finishes for prolonged exposure.

3. How do I determine the right size of T-slot aluminum extrusion for my project?

The right size of T-slot aluminum extrusion depends on the specific requirements of your project, including load-bearing capacity, dimensions, and design complexity. Consulting with a supplier or engineer can help you make an informed decision.

4. Are T-slot aluminum extrusions customizable?

Yes, T-slot aluminum extrusions can be customized in terms of length, profile shape, and surface finish. This flexibility allows for tailored solutions that meet specific project needs.

5. What industries commonly use T-slot aluminum extrusions?

T-slot aluminum extrusions are widely used in various industries, including automation, manufacturing, furniture design, and construction. Their versatility makes them suitable for a broad range of applications.