Content Menu

● Introduction

● Understanding T-Slot Aluminum Extrusions

● Benefits of T-Slot Aluminum Extrusions

>> Versatility

>> Lightweight and Durable

>> Easy Assembly

● Applications of T-Slot Aluminum Extrusions

>> Industrial Automation

>> Custom Workstations

>> Safety Guarding

● Choosing the Right T-Slot Aluminum Extrusion

>> Size and Load Capacity

>> Profile Type

>> Surface Finish

● Conclusion

● Related Questions

>> 1. What are the main advantages of using T-slot aluminum extrusions in automation systems?

>> 2. How can T-slot aluminum be used in custom workstations?

>> 3. What types of industries benefit from T-slot aluminum extrusions?

>> 4. How do T-slot aluminum extrusions compare to traditional materials like steel?

>> 5. Can T-slot aluminum extrusions be easily modified or reconfigured?

Introduction

T-slot aluminum extrusions have revolutionized the way we approach design and assembly in various industries, particularly in automation systems. These versatile components offer a unique combination of strength, lightweight properties, and modularity, making them an ideal choice for a wide range of applications. In this article, we will explore the benefits of T-slot aluminum extrusions, their applications in automation, and why they are considered a go-to solution for engineers and designers alike.

Understanding T-Slot Aluminum Extrusions

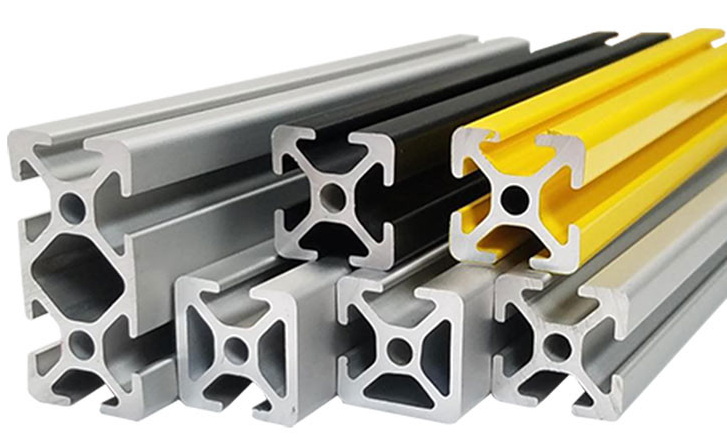

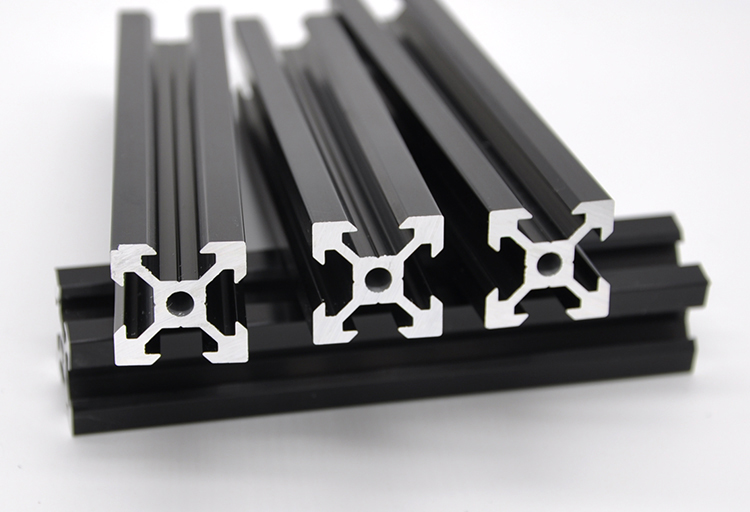

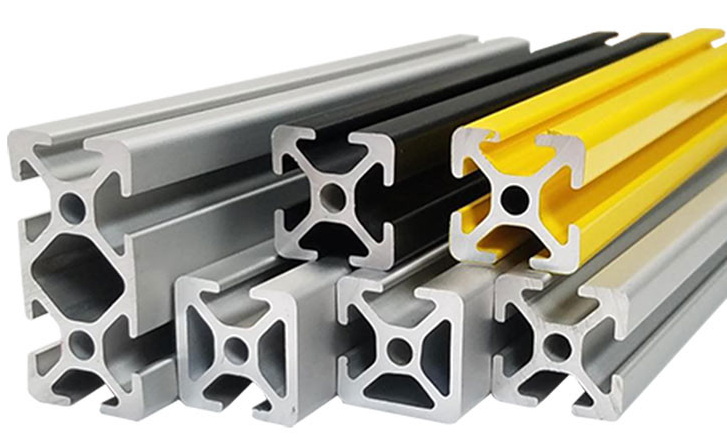

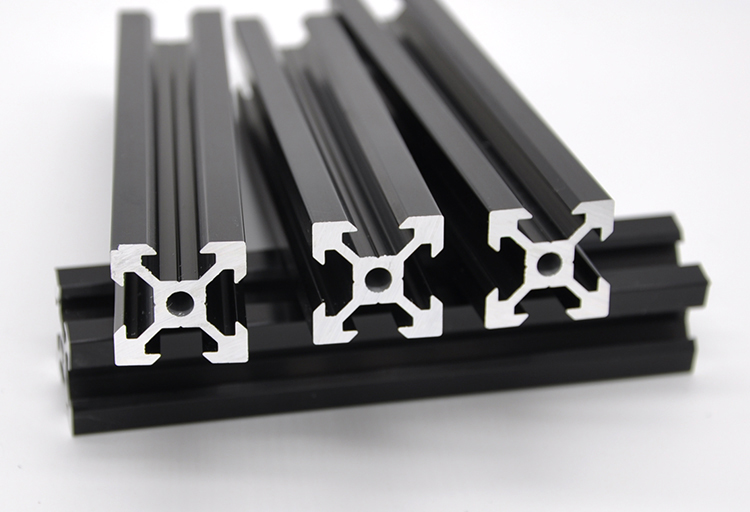

T-slot aluminum extrusions are structural components made from aluminum that feature a distinctive T-shaped slot along their length. This design allows for easy attachment of other components, such as brackets, panels, and fasteners, without the need for complex machining or welding. The extrusions are typically made from high-strength aluminum alloys, which provide excellent durability while remaining lightweight.

The versatility of T-slot aluminum extrusions stems from their modular nature. They can be easily cut to size and assembled in various configurations, allowing for customized solutions tailored to specific project requirements. This adaptability is particularly beneficial in automation systems, where flexibility and efficiency are paramount.

Benefits of T-Slot Aluminum Extrusions

Versatility

One of the primary advantages of T-slot aluminum extrusions is their versatility. They can be used in a multitude of applications, ranging from simple frames to complex automation systems. The ability to create custom structures means that engineers can design solutions that meet their exact specifications without being constrained by pre-fabricated components.

For instance, in an automation system, T-slot aluminum can be used to build everything from conveyor systems to robotic arms. The modular design allows for easy reconfiguration as project needs change, making it an ideal choice for industries that require frequent updates or modifications.

Lightweight and Durable

T-slot aluminum extrusions are significantly lighter than traditional materials such as steel or wood. This lightweight nature not only makes them easier to handle and transport but also reduces the overall weight of the automation system. This is particularly important in applications where weight is a critical factor, such as in robotics or mobile automation solutions.

Despite their lightweight properties, T-slot aluminum extrusions are incredibly strong and durable. The use of high-strength aluminum alloys ensures that these components can withstand heavy loads and resist deformation over time. This durability translates to lower maintenance costs and longer service life for automation systems.

Easy Assembly

The design of T-slot aluminum extrusions allows for quick and easy assembly. The T-slots enable components to be connected using simple fasteners, eliminating the need for complex tools or specialized skills. This ease of assembly not only speeds up the construction process but also allows for rapid prototyping and testing of new designs.

In automation systems, where time is often of the essence, the ability to quickly assemble and disassemble components can lead to significant efficiency gains. Engineers can easily modify or upgrade systems without extensive downtime, ensuring that production processes remain uninterrupted.

Applications of T-Slot Aluminum Extrusions

Industrial Automation

T-slot aluminum extrusions are widely used in industrial automation applications. They serve as the backbone for various systems, including conveyor belts, assembly lines, and robotic workstations. The modular nature of these extrusions allows for the creation of custom layouts that optimize workflow and enhance productivity.

For example, a manufacturer may use T-slot aluminum to construct a conveyor system that transports products between different stages of production. The ability to easily adjust the height and angle of the conveyor using T-slot components ensures that the system can be tailored to the specific needs of the operation.

Custom Workstations

Another significant application of T-slot aluminum extrusions is in the creation of custom workstations. These workstations can be designed to accommodate specific tasks, tools, and workflows, enhancing ergonomics and efficiency. By utilizing T-slot aluminum, companies can create flexible work environments that adapt to the changing needs of their workforce.

For instance, a custom workstation built from T-slot aluminum can include integrated storage solutions, adjustable surfaces, and mounting points for tools and equipment. This level of customization ensures that workers have everything they need within reach, reducing the time spent searching for tools and increasing overall productivity.

Safety Guarding

Safety is a critical concern in any industrial environment, and T-slot aluminum extrusions can play a vital role in enhancing workplace safety. These extrusions can be used to construct safety guarding systems that protect workers from moving machinery and hazardous areas.

By using T-slot aluminum, companies can create robust safety barriers that are easy to install and modify as needed. The modular design allows for quick adjustments to the guarding system, ensuring that safety measures can keep pace with changes in the production environment.

Choosing the Right T-Slot Aluminum Extrusion

When selecting T-slot aluminum extrusions for a project, several factors should be considered to ensure the best fit for specific needs.

Size and Load Capacity

The size of the T-slot aluminum extrusion is crucial, as it must be able to support the intended load without bending or deforming. Engineers should assess the weight of the components that will be attached to the extrusion and choose a profile that can handle the load.

Profile Type

T-slot aluminum extrusions come in various profiles, each designed for specific applications. Common profiles include square, rectangular, and round shapes. The choice of profile will depend on the requirements of the project, including the desired aesthetics and functionality.

Surface Finish

The surface finish of T-slot aluminum extrusions can also impact their performance. Anodized finishes provide additional protection against corrosion and wear, making them suitable for harsh environments. Engineers should consider the operating conditions when selecting the appropriate finish for their extrusions.

Conclusion

T-slot aluminum extrusions are a versatile and practical solution for automation systems. Their lightweight, durable, and modular nature makes them ideal for a wide range of applications, from industrial automation to custom workstations and safety guarding. By understanding the benefits and applications of T-slot aluminum, engineers and designers can leverage these components to create efficient and effective automation solutions.

Related Questions

1. What are the main advantages of using T-slot aluminum extrusions in automation systems?

T-slot aluminum extrusions offer versatility, lightweight properties, durability, and ease of assembly, making them ideal for various automation applications.

2. How can T-slot aluminum be used in custom workstations?

T-slot aluminum can be used to create flexible and ergonomic workstations tailored to specific tasks, enhancing productivity and worker comfort.

3. What types of industries benefit from T-slot aluminum extrusions?

Industries such as manufacturing, robotics, packaging, and automotive frequently utilize T-slot aluminum extrusions for their modular and adaptable nature.

4. How do T-slot aluminum extrusions compare to traditional materials like steel?

T-slot aluminum extrusions are lighter than steel, making them easier to handle, while still providing comparable strength and durability.

5. Can T-slot aluminum extrusions be easily modified or reconfigured?

Yes, the modular design of T-slot aluminum extrusions allows for easy modification and reconfiguration, making them suitable for projects that require flexibility.