Content Menu

● Introduction to Shashi Extrusion Machinery

● Key Features of Shashi Extrusion Machinery

>> 1. Diverse Range of Solutions

>> 2. Precision Engineering and Reliability

>> 3. High-Volume Production Capability

>> 4. Sustainable Waste Processing

● Advantages of Shashi Extrusion Machinery

>> 1. Strong Market Presence and Clientele

>> 2. Cost-Effectiveness and Efficiency

>> 3. Customization and Technical Support

>> 4. Innovation and Adaptability

● Shashi Extrusion Machinery in the Global Market Context

● Technical Innovations by Shashi Extrusion Machinery

>> 1. Advanced Screw Barrel Technology

>> 2. Underwater Palletizer Systems

>> 3. Sustainable Pelletizer Units

● Customer-Centric Approach

● Conclusion

● FAQ

>> 1. What types of extrusion machinery does Shashi manufacture?

>> 2. How does Shashi ensure the quality and reliability of its machines?

>> 3. Does Shashi Extrusion Machinery support sustainable manufacturing practices?

>> 4. In which countries does Shashi Extrusion Machinery have a market presence?

>> 5. What kind of after-sales support does Shashi provide?

● Citations:

In the highly competitive field of plastic and adhesive extrusion machinery, Shashi Extrusion Machinery has carved a distinct niche for itself. With decades of experience and a strong commitment to innovation, quality, and customer satisfaction, Shashi has become a trusted name not only in India but also in international markets such as Bangladesh, Brazil, Dubai, Kenya, Oman, Madagascar, and Nigeria. This article explores the various factors that make Shashi Extrusion Machinery stand out in the market, detailing its features, advantages, and market positioning.

Introduction to Shashi Extrusion Machinery

Shashi Extrusion Machinery is a leading manufacturer specializing in machines and components used predominantly in the plastic and adhesive extrusion industries. Established in 1987, the company has grown steadily by supplying over 150 machines across India and exporting to multiple countries worldwide[1].

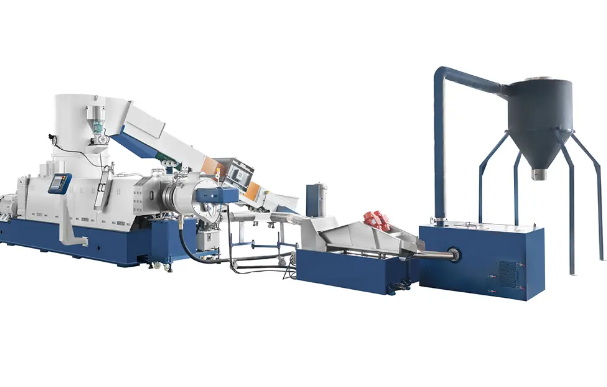

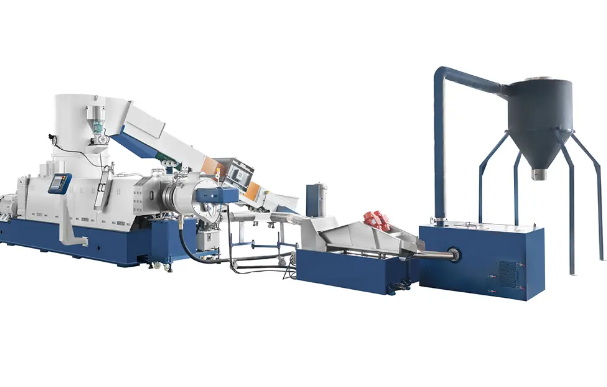

Plastic extrusion is a manufacturing process where heated plastic is shaped into continuous profiles through a die. Adhesive extrusion involves dispensing adhesive material through a nozzle for precise bonding applications. Shashi's expertise covers both these processes, offering versatile machinery solutions tailored to high-volume production needs.

Key Features of Shashi Extrusion Machinery

1. Diverse Range of Solutions

Shashi Extrusion Machinery offers a comprehensive range of products, including:

- Plastic extrusion machines

- Adhesive extrusion machines

- Washing and drying lines for material processing

- Screw barrels for extrusion and molding machines

- Plastic extrusion accessories and spare parts

- Underwater palletizers to improve product handling and reduce damage during stacking[1]

This diversity allows Shashi to cater to a wide spectrum of manufacturing requirements, making it a one-stop solution provider in extrusion technology.

2. Precision Engineering and Reliability

The machinery from Shashi is known for its precision engineering, which ensures consistent quality and performance. Screw barrels, a critical component in extrusion, are manufactured to exacting standards to guarantee melting, mixing, and transporting materials with high precision and consistency. This attention to detail results in machines that deliver reliable output and long service life[1].

3. High-Volume Production Capability

Shashi machines are designed for high-volume production where time efficiency is crucial. The company's extrusion machinery supports rapid processing without compromising on quality, making it ideal for industries that demand both speed and precision[1].

4. Sustainable Waste Processing

Shashi has pioneered pelletizer units for sustainable waste processing. These units enable resource recovery by extracting and recycling plastic waste, aligning with global trends toward environmental responsibility and circular economy practices[1].

Advantages of Shashi Extrusion Machinery

1. Strong Market Presence and Clientele

With over 150 machines supplied across India and exports to several countries, Shashi has built a robust clientele base. This extensive market presence is a testament to the trust and satisfaction of its customers globally[1].

2. Cost-Effectiveness and Efficiency

Shashi Extrusion Machinery offers competitive pricing without compromising on quality. The machines are engineered to maximize efficiency, reducing operational costs and increasing throughput for manufacturers[1].

3. Customization and Technical Support

The company provides customized solutions tailored to specific production needs. Additionally, Shashi offers strong after-sales support and readily available spare parts, ensuring minimal downtime and smooth operation for clients[1].

4. Innovation and Adaptability

Shashi continuously innovates to keep pace with technological advancements in extrusion processes. Its ability to adapt and upgrade machinery ensures clients benefit from the latest features and improved performance[1].

Shashi Extrusion Machinery in the Global Market Context

While China dominates the global plastic extrusion machinery market with its low-cost, high-quality machines, Shashi Extrusion Machinery holds a significant position, particularly in India and neighboring countries. The company's focus on precision, sustainability, and customer-centric solutions differentiates it from many competitors[3][1].

China's extrusion machinery market is characterized by rapid growth and technological adoption, but Shashi's niche lies in providing specialized, reliable machines for high-volume production with strong technical support and customization options[3][1].

Technical Innovations by Shashi Extrusion Machinery

1. Advanced Screw Barrel Technology

The screw barrel is essential in extrusion machinery for melting and mixing materials. Shashi's precision manufacturing of screw barrels ensures uniform melting and consistent material flow, which is critical for product quality[1].

2. Underwater Palletizer Systems

Shashi offers underwater palletizers that stack products underwater to minimize damage and enhance handling efficiency. This innovation is particularly useful in industries where product integrity during packaging is paramount[1].

3. Sustainable Pelletizer Units

The company's pelletizer units for sustainable waste processing contribute to environmental sustainability by enabling efficient plastic waste recycling, reducing environmental impact, and promoting resource recovery[1].

Customer-Centric Approach

Shashi Extrusion Machinery's success is also attributed to its customer-centric approach. The company emphasizes understanding client requirements, providing tailored solutions, and ensuring after-sales service excellence. This approach has fostered long-term relationships and repeat business from satisfied customers[1].

Conclusion

Shashi Extrusion Machinery stands out in the market due to its comprehensive range of precision-engineered extrusion machines, commitment to sustainability, high-volume production capabilities, and strong customer support. Its ability to deliver cost-effective, reliable, and innovative solutions has earned it a solid reputation in India and international markets. As the extrusion industry evolves, Shashi's focus on innovation and customer satisfaction positions it well for continued growth and leadership.

FAQ

1. What types of extrusion machinery does Shashi manufacture?

Shashi manufactures a diverse range of extrusion machinery including plastic extrusion machines, adhesive extrusion machines, washing and drying lines, screw barrels, extrusion accessories, and underwater palletizers[1].

2. How does Shashi ensure the quality and reliability of its machines?

Shashi employs precision engineering, especially in critical components like screw barrels, and maintains strict quality control standards to ensure consistent performance and long service life of its machines[1].

3. Does Shashi Extrusion Machinery support sustainable manufacturing practices?

Yes, Shashi has developed pelletizer units for sustainable waste processing that enable plastic recycling and resource recovery, supporting environmental sustainability[1].

4. In which countries does Shashi Extrusion Machinery have a market presence?

Besides India, Shashi has exported machines to Bangladesh, Brazil, Dubai, Kenya, Oman, Madagascar, Nigeria, and other countries, building a strong international clientele[1].

5. What kind of after-sales support does Shashi provide?

Shashi offers robust after-sales support including spare parts availability, technical assistance, and customization services to ensure smooth operation and minimal downtime for clients[1].

Citations:

[1] https://plastsem.com

[2] https://journals.sagepub.com/doi/10.1177/0954405414535581?icid=int.sj-full-text.similar-articles.1

[3] https://www.jwellmachine.com/popular-china-plastic-extrusion-machine-dominates-the-global-market/

[4] https://axiscapital.co.in/contents/Polycab-India-Limited-RHP.pdf

[5] https://plastsem.com/plastic-extrusion-menu/

[6] https://www.indiamart.com/shashiextrusionmachinery/

[7] https://www.indiamart.com/shashiextrusionmachinery/about-us.html

[8] https://cn.linkedin.com/in/allen-wei-7a825531a/zh-cn

[9] https://www.exportersindia.com/shashi-fluoroplastiks/plastic-component.htm

[10] https://in.linkedin.com/in/sk10

[11] https://mkp.gem.gov.in/polythene-liner/shashi-packaging-shashipackaging-polythene-liner-black/p-5116877-57919209321-cat.html

[12] https://www.justdial.com/Delhi/Cotton-Wick-Making-Machine-Manufacturers-in-Shashi-Garden-Mayur-Vihar-Phase-1/nct-12011422

[13] https://www.justdial.com/Delhi/Machinery-Dealers-in-Shashi-Garden-Mayur-Vihar-Phase-1/nct-10565272

[14] https://in.linkedin.com/in/shashi-kant-sharma-8596b644

[15] https://economictimes.com/news/politics-and-nation/congress-should-be-a-party-of-hope-not-just-criticism-shashi-tharoor/articleshow/120137696.cms

[16] https://gpkolhapur.ac.in/wp-content/uploads/2022/05/Industrial-Electronics-MPECs2020-1-Mohini-Sovani.pdf

[17] https://economictimes.com/news/newsblogs/budget-2025-live-updates-union-budget-finance-minister-nirmala-sitharaman-speech-live-key-announcements-customs-duty-tax-takeaways-1-feb-budget-impacts-latest-news/liveblog/117807015.cms