Content Menu

● Introduction

● Understanding 40x40 Aluminum Profiles

● Advantages of Using 40x40 Aluminum Profiles

>> Strength and Durability

>> Lightweight Nature

>> Corrosion Resistance

● Applications of 40x40 Aluminum Profiles

>> Modular Construction

>> Industrial Machinery

>> DIY Projects

● Choosing the Right Aluminum Extrusion

>> Factors to Consider

● Conclusion

● Related Questions

>> 1. What are the main benefits of using 40x40 aluminum extrusions in construction?

>> 2. Can 40x40 aluminum profiles be used for outdoor applications?

>> 3. How do I choose the right aluminum extrusion for my project?

>> 4. Are modular aluminum extrusions easy to assemble?

>> 5. What types of projects can benefit from using 40x40 aluminum extrusions?

Introduction

In the world of construction and manufacturing, the demand for versatile and efficient building materials has never been higher. Among these materials, modular aluminum extrusions, particularly the 40x40 aluminum extrusion, have emerged as a popular choice for custom builds. These extrusions offer a unique combination of strength, lightweight properties, and adaptability, making them ideal for a wide range of applications. This article explores the benefits of modular aluminum extrusions, their applications, and why they are the go-to solution for custom builds.

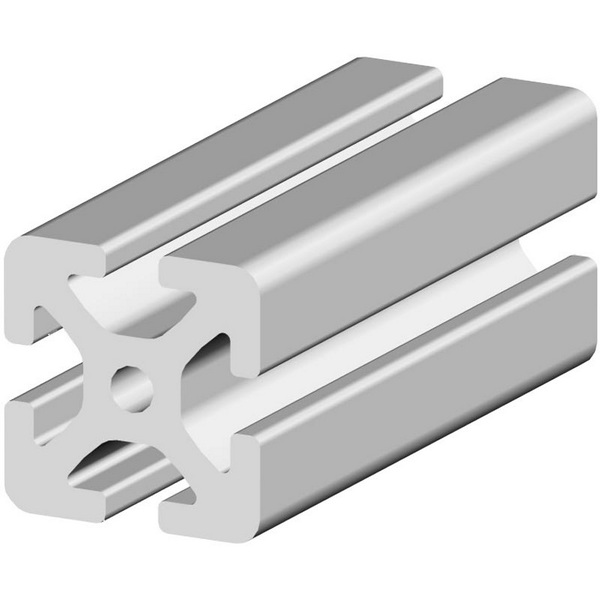

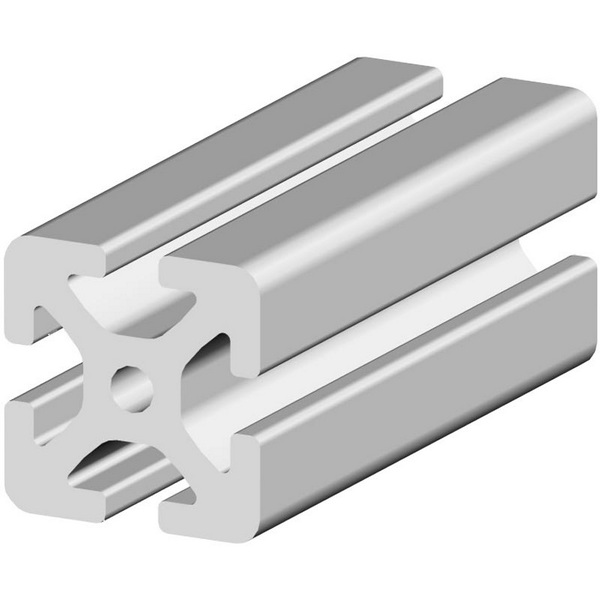

Understanding 40x40 Aluminum Profiles

The 40x40 aluminum profile is a specific size of aluminum extrusion that features a square cross-section measuring 40mm by 40mm. This profile is part of a larger family of T-slot aluminum extrusions, which are designed with grooves that allow for easy assembly and integration with various components. The 40x40 aluminum extrusion is particularly favored for its balance of strength and weight, making it suitable for both structural and aesthetic applications.

One of the key characteristics of the 40x40 aluminum profile is its modularity. This means that it can be easily combined with other profiles and components to create custom structures. The T-slot design allows for the attachment of brackets, connectors, and other accessories, enabling builders to create complex assemblies without the need for specialized tools or extensive fabrication.

Advantages of Using 40x40 Aluminum Profiles

Strength and Durability

One of the primary advantages of using 40x40 aluminum profiles is their exceptional strength-to-weight ratio. Aluminum is known for its lightweight nature, which makes it easier to handle and transport. However, it also possesses remarkable strength, allowing it to support significant loads without bending or breaking. This makes the 40x40 aluminum extrusion an ideal choice for applications where structural integrity is crucial, such as in machinery frames, workstations, and display stands.

Additionally, aluminum is naturally resistant to corrosion, which enhances the longevity of structures built with 40x40 aluminum profiles. This resistance is further improved when the aluminum is anodized, creating a protective layer that prevents oxidation and wear. As a result, projects utilizing 40x40 aluminum extrusions can withstand harsh environmental conditions, making them suitable for both indoor and outdoor applications.

Lightweight Nature

The lightweight nature of 40x40 aluminum extrusions is another significant advantage. This property not only simplifies transportation and installation but also reduces the overall weight of the final structure. In industries where weight is a critical factor, such as aerospace and automotive, using lightweight materials can lead to improved efficiency and performance.

For example, in custom builds for machinery, using 40x40 aluminum profiles can help reduce the overall weight of the equipment, leading to lower energy consumption and easier mobility. This is particularly beneficial in applications where equipment needs to be frequently moved or adjusted.

Corrosion Resistance

Aluminum's inherent corrosion resistance is a game changer for many applications. Unlike steel, which can rust and degrade over time, aluminum maintains its integrity even in challenging environments. This makes 40x40 aluminum extrusions an excellent choice for outdoor structures, such as canopies, railings, and frames for solar panels.

Furthermore, the anodization process enhances this property, providing an additional layer of protection against the elements. Anodized aluminum extrusions are not only more durable but also available in various colors and finishes, allowing for aesthetic customization without sacrificing performance.

Applications of 40x40 Aluminum Profiles

Modular Construction

One of the most significant applications of 40x40 aluminum profiles is in modular construction. The ability to easily connect and disconnect components makes these extrusions ideal for creating temporary or permanent structures. For instance, in the event of a trade show or exhibition, modular aluminum extrusions can be used to build customizable booths that can be reconfigured for different events.

The flexibility of modular construction allows for rapid assembly and disassembly, reducing downtime and labor costs. Builders can create everything from simple frames to complex multi-level structures using 40x40 aluminum profiles, making them a versatile choice for various projects.

Industrial Machinery

In industrial settings, 40x40 aluminum extrusions are commonly used to construct machine frames, supports, and enclosures. Their strength and lightweight properties make them ideal for building equipment that requires stability without excessive weight. For example, assembly lines often utilize aluminum extrusions to create workstations that can be easily adjusted or expanded as production needs change.

Moreover, the modular nature of these profiles allows for easy integration with other components, such as conveyor systems and robotic arms. This adaptability is crucial in modern manufacturing environments, where efficiency and flexibility are paramount.

DIY Projects

The popularity of 40x40 aluminum extrusions extends beyond industrial applications; they are also favored by hobbyists and DIY enthusiasts. The ease of assembly and customization makes these profiles perfect for a wide range of projects, from furniture to custom shelving units.

For instance, a DIY enthusiast can use 40x40 aluminum profiles to create a custom desk that fits perfectly in their workspace. The ability to design and build unique solutions tailored to individual needs is a significant draw for many people, making aluminum extrusions a popular choice in the maker community.

Choosing the Right Aluminum Extrusion

When selecting aluminum extrusions for a project, several factors should be considered to ensure the best results. First and foremost, it is essential to assess the specific requirements of the project, including load-bearing capacity, environmental conditions, and aesthetic preferences.

Factors to Consider

1. Load Requirements: Determine the weight and stress that the structure will need to support. The 40x40 aluminum extrusion is suitable for a variety of loads, but understanding the specific requirements will help in selecting the right profile.

2. Environmental Conditions: Consider whether the structure will be used indoors or outdoors. If exposed to the elements, opting for anodized aluminum profiles can provide additional protection against corrosion.

3. Compatibility with Accessories: Ensure that the chosen aluminum extrusion is compatible with the necessary connectors, brackets, and other accessories. The T-slot design of the 40x40 aluminum profile allows for a wide range of attachments, making it easier to create custom solutions.

4. Aesthetic Preferences: Aluminum extrusions are available in various finishes and colors. Consider the desired look of the final product and choose profiles that align with the overall design vision.

Conclusion

Modular aluminum extrusions, particularly the 40x40 aluminum profile, offer a wealth of benefits for custom builds. Their strength, lightweight nature, and corrosion resistance make them ideal for a wide range of applications, from industrial machinery to DIY projects. The modularity of these extrusions allows for easy assembly and customization, making them a versatile choice for builders and manufacturers alike.

As the demand for efficient and adaptable building materials continues to grow, 40x40 aluminum extrusions will undoubtedly play a significant role in shaping the future of construction and manufacturing.

Related Questions

1. What are the main benefits of using 40x40 aluminum extrusions in construction?

The main benefits include their strength-to-weight ratio, corrosion resistance, and modularity, allowing for easy assembly and customization.

2. Can 40x40 aluminum profiles be used for outdoor applications?

Yes, 40x40 aluminum profiles are suitable for outdoor applications due to their natural corrosion resistance and the option for anodized finishes.

3. How do I choose the right aluminum extrusion for my project?

Consider factors such as load requirements, environmental conditions, compatibility with accessories, and aesthetic preferences when selecting aluminum extrusions.

4. Are modular aluminum extrusions easy to assemble?

Yes, modular aluminum extrusions are designed for easy assembly, often requiring no specialized tools, making them accessible for both professionals and DIY enthusiasts.

5. What types of projects can benefit from using 40x40 aluminum extrusions?

Projects ranging from industrial machinery and workstations to custom furniture and display stands can benefit from the versatility and strength of 40x40 aluminum extrusions.