Content Menu

● The Importance of Aluminum Extrusion

● Strategic Location

● A Skilled Workforce

● Key Players in Michigan's Aluminum Extrusion Market

● Innovations Driving Growth

● Challenges Facing the Industry

● Conclusion

● Frequently Asked Questions

>> 1. What types of industries rely on aluminum extrusions?

>> 2. How does Michigan support its aluminum extrusion companies?

>> 3. What are some leading aluminum extrusion companies in Michigan?

>> 4. What innovations are impacting the aluminum extrusion industry?

>> 5. What challenges do aluminum extrusion companies face?

Michigan has established itself as a critical hub for aluminum extrusion companies, thanks to a combination of strategic location, a skilled workforce, and a robust industrial ecosystem. This article explores the factors contributing to Michigan's prominence in the aluminum extrusion industry, highlighting key companies, innovations, and market trends.

The Importance of Aluminum Extrusion

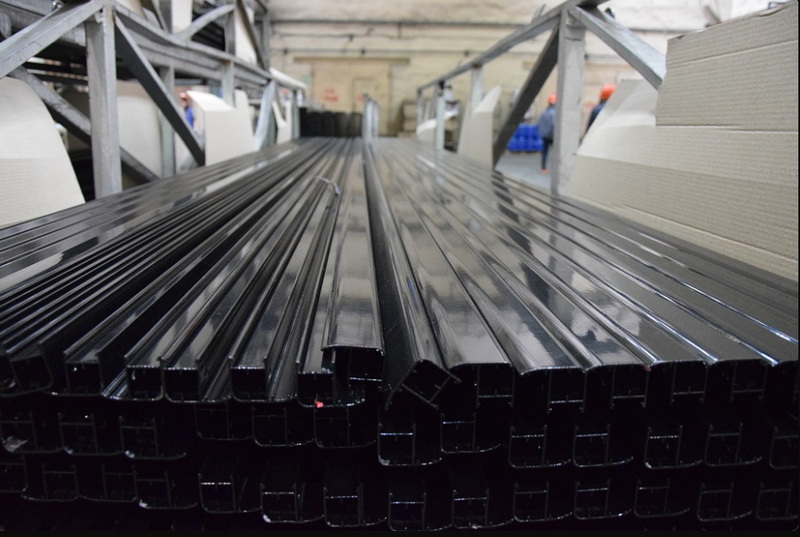

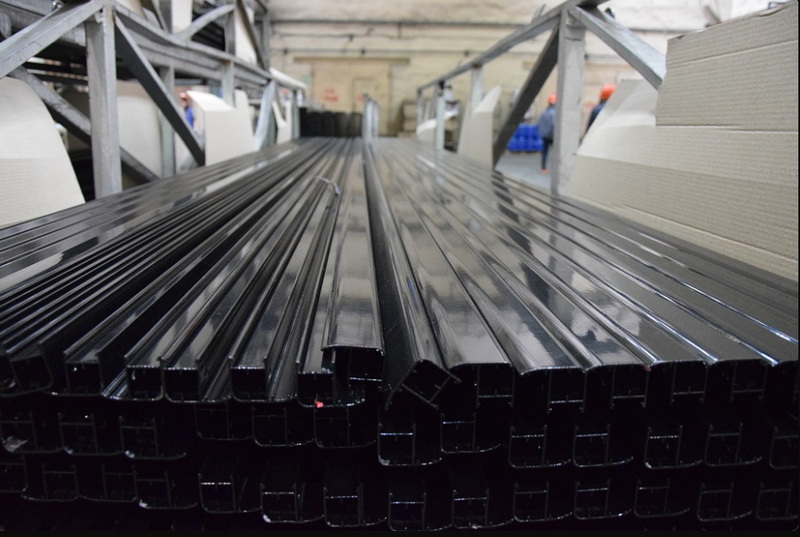

Aluminum extrusion is a manufacturing process that shapes aluminum alloys into desired cross-sectional profiles. This technique is widely used across various industries, including automotive, aerospace, construction, and consumer goods. The benefits of aluminum extrusions include:

- Lightweight and Strong: Aluminum is known for its high strength-to-weight ratio, making it ideal for applications where weight savings are crucial.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, enhancing its durability in harsh environments.

- Versatility: The extrusion process allows for complex shapes and designs, accommodating a wide range of applications.

- Recyclability: Aluminum is infinitely recyclable without loss of quality, making it an environmentally friendly choice.

Strategic Location

Michigan's strategic location in the Midwest provides easy access to major markets and transportation networks. The state is well-connected through highways, railroads, and waterways, facilitating the efficient movement of raw materials and finished products. This logistical advantage is particularly beneficial for industries reliant on just-in-time manufacturing practices.

A Skilled Workforce

Michigan boasts a rich history in manufacturing, particularly in the automotive sector. This legacy has cultivated a skilled workforce adept in engineering, machining, and production processes related to aluminum extrusion. Local educational institutions also offer specialized training programs to ensure that workers are equipped with the necessary skills to thrive in this industry.

Key Players in Michigan's Aluminum Extrusion Market

Several notable companies contribute to Michigan's status as an aluminum extrusion hub:

- Hydro Extrusion: As one of the largest aluminum extruders globally, Hydro operates multiple facilities in Michigan. They specialize in custom extrusions for various industries, including automotive and construction. Hydro's commitment to sustainability is evident through their investment in low-carbon aluminum production technologies.

- Dajcor Aluminum: Located near Detroit, Dajcor offers a comprehensive range of aluminum extrusion services. Their capabilities include fabrication and anodizing, making them a one-stop shop for clients seeking value-added services.

- Michigan Extruded Aluminum: This company focuses on producing high-quality aluminum extrusions for the architectural market. With a strong emphasis on customer service and innovation, they have established themselves as a reliable supplier.

- Penn Aluminum International: A veteran in the industry since 1923, Penn Aluminum specializes in custom extruded shapes and drawn tubing. Their extensive experience allows them to cater to diverse market needs effectively.

Innovations Driving Growth

The aluminum extrusion industry in Michigan is not just about traditional manufacturing; it also embraces innovation:

- Advanced Recycling Techniques: Companies like Hydro have implemented advanced recycling technologies that allow them to process post-consumer scrap efficiently. This not only reduces waste but also supports the production of low-carbon aluminum products.

- CAD Technology: Many manufacturers utilize Computer-Aided Design (CAD) software to create precise designs for custom extrusions. This technology enhances accuracy and reduces lead times.

- Sustainable Practices: The industry is increasingly focusing on sustainable practices, including energy-efficient production methods and environmentally friendly coatings. These initiatives align with global trends toward sustainability and responsible manufacturing.

Challenges Facing the Industry

Despite its strengths, Michigan's aluminum extrusion industry faces several challenges:

- Global Competition: The rise of low-cost manufacturing countries poses a threat to local producers. Companies must continuously innovate and improve efficiency to remain competitive.

- Supply Chain Disruptions: Recent global events have highlighted vulnerabilities in supply chains. Manufacturers need to develop more resilient supply chains to mitigate risks associated with material shortages or transportation delays.

- Regulatory Compliance: Adhering to environmental regulations can be challenging for manufacturers. Companies must invest in compliance measures while maintaining profitability.

Conclusion

Michigan's status as a hub for aluminum extrusion companies is supported by its strategic location, skilled workforce, and commitment to innovation. As the demand for aluminum products continues to grow across various industries, Michigan's manufacturers are well-positioned to meet these needs while embracing sustainable practices. The future looks bright for this sector as it adapts to challenges and leverages opportunities within the evolving market landscape.

Frequently Asked Questions

1. What types of industries rely on aluminum extrusions?

Aluminum extrusions are utilized across various industries including automotive, aerospace, construction, electronics, and consumer goods due to their lightweight strength and versatility.

2. How does Michigan support its aluminum extrusion companies?

Michigan provides a robust industrial infrastructure, access to transportation networks, and a skilled workforce trained in manufacturing processes essential for aluminum extrusion.

3. What are some leading aluminum extrusion companies in Michigan?

Notable companies include Hydro Extrusion, Dajcor Aluminum, Michigan Extruded Aluminum, and Penn Aluminum International among others.

4. What innovations are impacting the aluminum extrusion industry?

Innovations such as advanced recycling technologies, CAD design software, and sustainable manufacturing practices are significantly enhancing efficiency and product quality within the industry.

5. What challenges do aluminum extrusion companies face?

Challenges include global competition from low-cost manufacturers, supply chain disruptions due to unforeseen events, and compliance with environmental regulations that can impact operational costs.