Content Menu

● Introduction to Italian Extrusion Machinery

● Key Features of Italian Extrusion Machinery

>> 1. Advanced Technology

>> 2. Customization

>> 3. Durability and Reliability

>> 4. Versatility

● Leading Italian Manufacturers

>> Presezzi Extrusion

>> Danieli Breda

>> OMAV

>> ICMA San Giorgio

>> Luigi Bandera

>> Bausano

● Applications of Italian Extrusion Machinery

● Latest Advancements in Italian Extrusion Machinery

● Case Studies Highlighting Italian Excellence

>> Case Study 1: Automotive Industry

>> Case Study 2: Packaging Industry

● Future Trends in Italian Extrusion Machinery

● Conclusion

● FAQ Section

>> 1. What industries benefit the most from Italian extrusion machinery?

>> 2. How do Italian manufacturers ensure energy efficiency?

>> 3. Can Italian extrusion machines handle recycled materials?

>> 4. Are Italian machines customizable for specific applications?

>> 5. What makes Italian machinery globally competitive?

Italian extrusion machinery has earned global recognition for its innovation, craftsmanship, and versatility. From aluminum extrusion presses to plastic extrusion lines, Italy boasts a long tradition of engineering excellence coupled with cutting-edge technology. This article explores the key factors that make Italian extrusion machinery exceptional, highlighting its unique features, applications, and contributions to the global market.

Introduction to Italian Extrusion Machinery

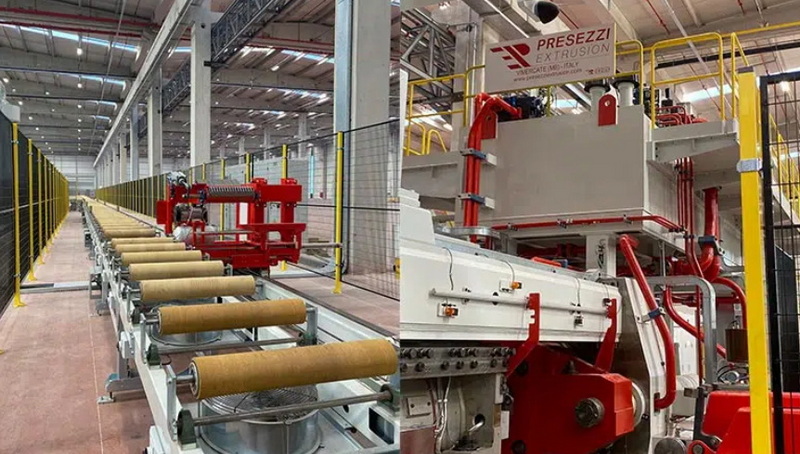

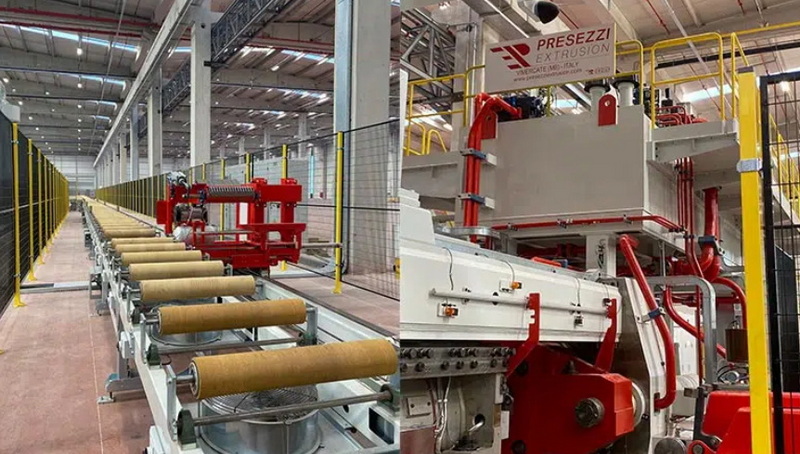

Extrusion machinery is critical for manufacturing processes across industries such as automotive, construction, aerospace, and consumer goods. Italy is home to several renowned manufacturers specializing in extrusion technology, including Presezzi Extrusion, Danieli Breda, OMAV, ICMA San Giorgio, Luigi Bandera, and Bausano. These companies have pioneered advancements in energy efficiency, automation, and material innovation.

Key Features of Italian Extrusion Machinery

1. Advanced Technology

Italian manufacturers integrate state-of-the-art technologies into their extrusion machinery:

- Energy Efficiency: Companies like Presezzi Extrusion and Turla focus on energy-efficient systems that reduce operational costs while maintaining high production levels.

- Automation: Automation technologies improve precision and reduce labor costs.

- Material Innovation: Manufacturers explore advanced alloys and polymers for improved strength-to-weight ratios and corrosion resistance.

2. Customization

Italian manufacturers excel in offering tailored solutions:

- Luigi Bandera specializes in designing custom plastic extrusion lines for packaging and converting applications.

- Bausano provides fully customizable extrusion lines for PVC, HDPE, PP pipes, medical tubes, and more.

3. Durability and Reliability

Italian machinery is known for its robust construction and long-term reliability:

- Companies like Turla emphasize quality control throughout the manufacturing process to ensure durability.

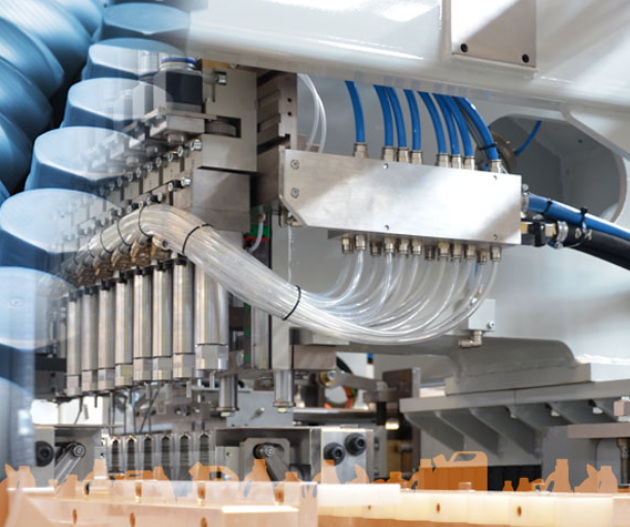

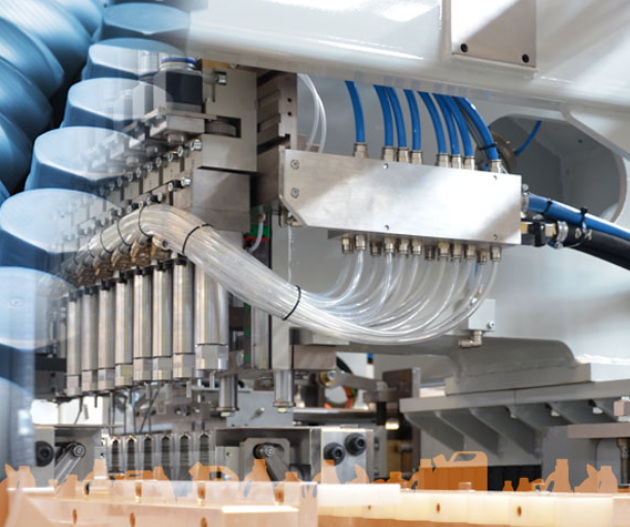

- ICMA San Giorgio's co-rotating twin-screw extruders are designed for high-performance recycling and compounding tasks.

4. Versatility

Italian extrusion machines cater to diverse applications:

- From aluminum profiles used in construction to plastic sheets for automotive interiors, Italian machinery serves a wide range of industries.

- ICMA's direct extrusion systems combine compounding and extrusion phases in one step for energy savings.

Leading Italian Manufacturers

Presezzi Extrusion

Founded in 1994, Presezzi specializes in aluminum extrusion presses with advanced automation technologies. Their robust R&D department ensures continuous innovation.

Danieli Breda

With over 50 years of experience, Danieli Breda designs machines for non-ferrous metals. Their focus on productivity and quality makes them a global leader.

OMAV

Established in 1952, OMAV offers complete aluminum extrusion lines with advanced handling systems. Now part of SMS Group, OMAV benefits from enhanced technological capabilities.

ICMA San Giorgio

ICMA's co-rotating twin-screw extruders are ideal for recycling and compounding applications. Their lab-scale units enable production trials at the highest standards.

Luigi Bandera

A pioneer in plastic extrusion technology since 1947, Bandera specializes in blown film and sheet extrusion lines tailored to customer needs.

Bausano

Known for its customizable plastic extrusion lines, Bausano's latest innovations include recycling extruders for polyolefins and PVC regranulation.

Applications of Italian Extrusion Machinery

Italian extrusion machinery supports diverse industries:

- Construction: Aluminum profiles for windows and doors.

- Automotive: Lightweight structures such as frames and bumpers.

- Aerospace: High-strength components.

- Medical: Tubes and bags compliant with special regulations.

- Packaging: Plastic films for food packaging.

Latest Advancements in Italian Extrusion Machinery

Italian manufacturers continue to push the boundaries of innovation by adopting new technologies:

1. Smart Manufacturing: Integration of IoT-enabled sensors allows real-time monitoring of machine performance. This ensures predictive maintenance and minimizes downtime.

2. Sustainability Focus: Manufacturers are increasingly adopting eco-friendly practices by designing machines that consume less energy while enabling efficient recycling processes.

3. High-Speed Production Lines: Companies like Luigi Bandera have developed high-speed blown film lines that enhance production rates without compromising quality.

4. Advanced Control Systems: Modern extrusion machines feature touchscreen interfaces with AI-based controls for optimized operations.

Case Studies Highlighting Italian Excellence

Case Study 1: Automotive Industry

An Italian manufacturer supplied lightweight aluminum extrusion profiles to a leading carmaker. These profiles reduced vehicle weight by 20%, improving fuel efficiency without compromising safety standards.

Case Study 2: Packaging Industry

Luigi Bandera collaborated with a food packaging company to develop a custom blown film line capable of producing biodegradable plastic films. This innovation supported the company's sustainability goals while meeting high production demands.

Future Trends in Italian Extrusion Machinery

The future of Italian extrusion machinery is shaped by several trends:

1. Digitalization: Increased adoption of Industry 4.0 technologies will enhance machine connectivity and data-driven decision-making.

2. Circular Economy Solutions: Recycling-focused innovations will dominate as manufacturers address global environmental concerns.

3. Global Expansion: Italian companies are expanding their presence in emerging markets like Asia-Pacific due to growing demand for high-quality machinery.

4. Material Advancements: Research into lightweight composites will further diversify applications across industries such as aerospace and automotive.

Conclusion

Italian extrusion machinery stands out due to its integration of advanced technologies, customization options, durability, and versatility. Leading manufacturers like Presezzi Extrusion, Danieli Breda, OMAV, ICMA San Giorgio, Luigi Bandera, and Bausano continue to innovate and adapt to industry demands. Their contributions ensure Italy remains at the forefront of global manufacturing.

FAQ Section

1. What industries benefit the most from Italian extrusion machinery?

Italian extrusion machinery serves industries such as automotive (frames), aerospace (lightweight structures), construction (aluminum profiles), medical (tubes), and packaging (plastic films).

2. How do Italian manufacturers ensure energy efficiency?

Manufacturers like Presezzi Extrusion implement energy-saving technologies such as optimized heating elements and automation systems to reduce operational costs while maintaining production levels.

3. Can Italian extrusion machines handle recycled materials?

Yes! ICMA San Giorgio specializes in recycling lines equipped with co-rotating extruders that enable efficient processing of recycled plastics.

4. Are Italian machines customizable for specific applications?

Absolutely! Companies like Luigi Bandera design tailored solutions for blown film lines or rigid sheets based on customer requirements. Bausano also offers fully customizable options for medical-grade products.

5. What makes Italian machinery globally competitive?

Italian machinery combines craftsmanship with modern technology. Features like automation integration, material innovation, and strict quality control make it a strategic force in global markets.