Content Menu

● The Legacy and Vision of Haisi Extrusion Equipment

>> Company Background

>> Commitment to Innovation

● Technological Excellence: What Sets Haisi Apart?

>> Advanced Engineering and Manufacturing

>> Product Range and Customization

>> Material Versatility

● Key Features and Advantages of Haisi Extrusion Equipment

>> 1. Superior Mixing and Compounding

>> 2. High Output and Efficiency

>> 3. Durability and Reliability

>> 4. Easy Maintenance and Operation

>> 5. Comprehensive Quality Assurance

● Global Reach and Industry Impact

>> International Presence

>> Diverse Applications

● Customer-Centric Service and Support

>> Turnkey Solutions

>> After-Sales Support

>> OEM and Customization Services

● Innovation in Extrusion: Spotlight on Three-Screw Technology

● Quality Assurance and Certifications

>> Strict Adherence to Standards

>> Continuous Improvement

● Sustainability and Future Prospects

>> Energy Efficiency

>> Adapting to Emerging Trends

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What types of extruders does Haisi Extrusion Equipment offer?

>> 2. How does Haisi ensure the quality and reliability of its equipment?

>> 3. Can Haisi Extrusion Equipment be customized for specific applications?

>> 4. What support does Haisi provide after equipment installation?

>> 5. What are the main advantages of Haisi's three-screw extruder compared to traditional twin-screw models?

● Citations:

In the rapidly evolving world of plastics and rubber manufacturing, the right equipment can be the difference between innovation and stagnation. Among the leading names in extrusion technology, Haisi Extrusion Equipment has emerged as a top choice for manufacturers globally. With a reputation for robust engineering, advanced technology, and comprehensive customer support, Haisi Extrusion Equipment is redefining industry standards and enabling manufacturers to achieve new levels of productivity and quality.

This article explores the key factors that make Haisi Extrusion Equipment a preferred partner for manufacturers, delving into its technological innovations, product versatility, quality assurance, and service excellence. We will also address frequently asked questions to provide a holistic understanding of the brand's value proposition.

The Legacy and Vision of Haisi Extrusion Equipment

Company Background

Founded in Nanjing, China, Haisi Extrusion Equipment Co., Ltd. is a high-tech manufacturing and trading company specializing in the design, production, and servicing of extrusion machinery. The company's ethos is rooted in a “family” culture, emphasizing teamwork, efficiency, and shared goals to deliver the best quality extruders in China and beyond[1][2].

Commitment to Innovation

Haisi Extrusion Equipment is known for its relentless pursuit of innovation. The company invests heavily in research and development, continually refining its machinery to meet the dynamic needs of the plastics and rubber industries. This commitment ensures that their equipment is not only durable and efficient but also adaptable to emerging materials and processes[1][4].

Technological Excellence: What Sets Haisi Apart?

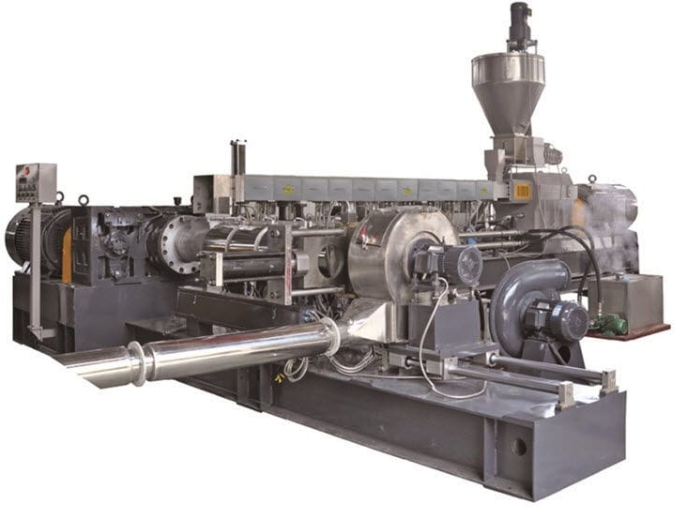

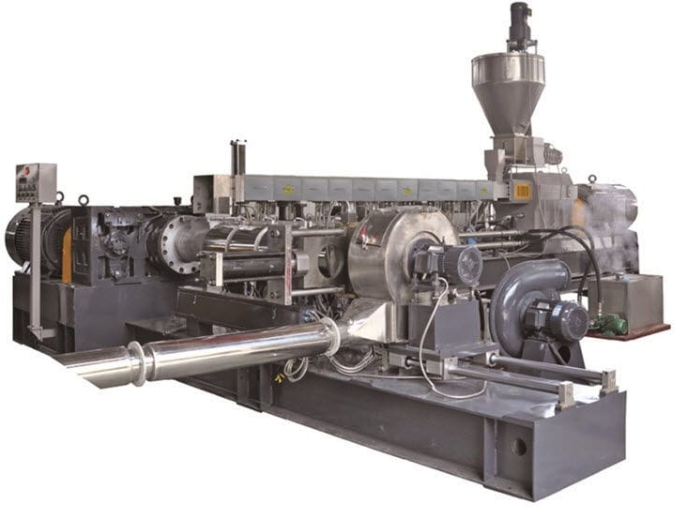

Advanced Engineering and Manufacturing

Haisi Extrusion Equipment boasts a state-of-the-art manufacturing facility equipped with CNC centers, grinding machines, cutters, and punchers. This infrastructure enables the production of over 200 models of extruders and spare parts, ensuring a broad product range that meets diverse customer requirements[1][5].

Product Range and Customization

The company's product portfolio includes:

- Twin Screw Extruders

- Single Screw Extruders

- Two-Stage Extrusion Lines

- Three-Screw Extruders

- Auxiliary Equipment (crushers, dryers, mixers)

Each machine is designed with modularity in mind, allowing for optimal configuration based on material properties and process requirements. The “toy bricks” principle enables flexible adjustments in screw configuration, barrel setup, feeding and venting modes, and granulating techniques[1].

Material Versatility

Haisi Extrusion Equipment is adept at handling a wide range of materials, including:

- Coloring/dyeing masterbatches

- Filling masterbatches

- Plastic modification and compounding

- Plastic recycling

This versatility is enhanced by the ability to supply turnkey projects, offering end-to-end solutions from design to installation[1][2][5].

Key Features and Advantages of Haisi Extrusion Equipment

1. Superior Mixing and Compounding

Haisi's twin-screw and three-screw extruders are engineered for optimal mixing, ensuring uniform dispersion of additives and fillers. The complex flow dynamics within the screws provide:

- Adequate mixing

- Good heat transfer

- High melting capacity

- Efficient exhaust and temperature control[3][6]

These features translate into higher product quality and consistency.

2. High Output and Efficiency

Haisi Extrusion Equipment is designed for high throughput without compromising on quality. The machines offer:

- High torque and speed

- Enhanced labor efficiency

- Reduced production costs

- Energy-efficient operation[3][6]

For instance, the three-screw extruder can double the output of a comparable twin-screw machine while maintaining low energy consumption[6].

3. Durability and Reliability

The use of premium materials, such as high-quality nitrided steel and tool steels like 38CrMoAlA or W6Mo5Cr4V2, ensures exceptional corrosion resistance and longevity. Advanced heat treatment processes further enhance the durability of critical components[1].

4. Easy Maintenance and Operation

Haisi's extruders are designed for ease of maintenance. Features such as easy-open barrels allow for quick inspection and cleaning, minimizing downtime during color changes or material transitions[3]. The modular design also facilitates straightforward repairs and upgrades.

5. Comprehensive Quality Assurance

All Haisi Extrusion Equipment is manufactured in strict accordance with CE and ISO9001 quality certification systems. Rigorous quality control measures are implemented at every stage, from material selection to final assembly, ensuring reliable performance and safety[1][5].

Global Reach and Industry Impact

International Presence

Haisi Extrusion Equipment has a strong domestic presence in China and exports to over 30 countries worldwide, including markets in Southeast Asia, the Middle East, Europe, and the Americas[1][2][5]. The company's annual production capacity stands at 240 sets of plastic extruders, reflecting its robust manufacturing capabilities[5].

Diverse Applications

Haisi's machines are used across a wide spectrum of industries, including:

- Plastics manufacturing

- Rubber processing

- Masterbatch production

- Recycling operations

- Specialty compounding

This broad applicability makes Haisi Extrusion Equipment a versatile choice for manufacturers seeking to diversify or scale their operations[2][4].

Customer-Centric Service and Support

Turnkey Solutions

Haisi Extrusion Equipment offers comprehensive turnkey solutions, from initial consultation and equipment selection to installation, commissioning, and training. This end-to-end approach ensures seamless integration into the customer's production environment[1][5].

After-Sales Support

The company prides itself on responsive after-sales service, providing:

- Spare parts availability

- Technical support and troubleshooting

- Regular updates and maintenance guidance

This commitment to customer satisfaction fosters long-term partnerships and repeat business[4].

OEM and Customization Services

Haisi Extrusion Equipment also provides OEM services, tailoring machines to specific customer requirements and industry standards. This flexibility is particularly valuable for manufacturers with unique process needs or regulatory considerations[1][5].

Innovation in Extrusion: Spotlight on Three-Screw Technology

While twin-screw extruders are industry staples, Haisi's three-screw extruder technology represents a significant leap forward. Key benefits include:

- High shear efficiency and plasticizing effect: Enhanced mixing and dispersion, ideal for demanding applications such as high-content masterbatches.

- Double output: Achieves twice the throughput of comparable twin-screw machines with similar power consumption.

- Shorter residence time: Reduces material degradation, making it suitable for heat-sensitive and degradable materials.

- Excellent exhaust performance: Ensures high product quality by preventing material accumulation and blockages[6].

This technological edge positions Haisi Extrusion Equipment at the forefront of extrusion innovation.

Quality Assurance and Certifications

Strict Adherence to Standards

Haisi Extrusion Equipment operates under stringent quality management systems, including:

- CE Certification: Compliance with European safety and performance standards.

- ISO9001 Certification: Comprehensive quality management across all processes.

These certifications provide assurance to customers regarding the reliability and safety of Haisi's products[1][5].

Continuous Improvement

The company's dedication to continuous improvement is evident in its ongoing investment in R&D, staff training, and process optimization. Regular feedback from customers is incorporated into product development, ensuring that Haisi Extrusion Equipment remains aligned with industry needs and technological advancements[1][4].

Sustainability and Future Prospects

Energy Efficiency

Haisi Extrusion Equipment is designed with sustainability in mind. Features such as optimized heating systems, efficient gear transmission, and reduced material waste contribute to lower energy consumption and a smaller environmental footprint[1][4].

Adapting to Emerging Trends

As the plastics and rubber industries evolve, Haisi continues to adapt its equipment for new materials, such as biodegradable plastics and advanced composites. This forward-thinking approach ensures that manufacturers can stay ahead of regulatory changes and market demands[2][4].

Conclusion

Haisi Extrusion Equipment stands out as a top choice for manufacturers due to its unwavering commitment to quality, innovation, and customer satisfaction. With a diverse product range, advanced engineering, and comprehensive service offerings, Haisi empowers manufacturers to achieve superior productivity, efficiency, and product quality. Whether you are seeking to expand your production capabilities, improve process efficiency, or explore new materials, Haisi Extrusion Equipment provides the technology and support needed to drive your success.

Frequently Asked Questions (FAQ)

1. What types of extruders does Haisi Extrusion Equipment offer?

Haisi Extrusion Equipment manufactures a comprehensive range of extruders, including single screw, twin screw, and three-screw extruders, as well as complete extrusion lines and auxiliary equipment like crushers, dryers, and mixers[1][2][5].

2. How does Haisi ensure the quality and reliability of its equipment?

All Haisi Extrusion Equipment is produced under strict CE and ISO9001 quality certification systems. The company uses high-grade materials, advanced manufacturing techniques, and rigorous quality control to ensure each machine meets international standards[1][5].

3. Can Haisi Extrusion Equipment be customized for specific applications?

Yes, Haisi offers extensive customization options, including OEM services. Machines can be tailored in terms of screw configuration, barrel setup, feeding systems, and control modes to meet the unique requirements of different materials and processes[1][5].

4. What support does Haisi provide after equipment installation?

Haisi Extrusion Equipment provides comprehensive after-sales support, including spare parts supply, technical assistance, troubleshooting, and regular maintenance guidance. Training and commissioning services are also available to ensure smooth operation[4].

5. What are the main advantages of Haisi's three-screw extruder compared to traditional twin-screw models?

Haisi's three-screw extruder offers higher shear efficiency, better plasticizing and dispersion, double the output with similar energy consumption, shorter material residence time, and superior exhaust performance, making it ideal for high-performance and heat-sensitive materials[6].

Citations:

[1] https://hsextruder.en.made-in-china.com

[2] https://haisiextruder.goldsupplier.com

[3] https://www.haisiextrusion.com/What-are-the-advantages-of-twin-screw-extruders-id41870477.html

[4] https://www.haisiextrusion.com

[5] https://www.tradeindia.com/products/twin-screw-extruder-machine-9048593.html

[6] https://www.haisiextrusion.com/Advantages-of-three-screw-extruder-id49558437.html

[7] https://www.haisiextrusion.com/index.html

[8] https://www.haisiextrusion.com/products.html

[9] https://www.directindustry.com/prod/nanjing-haisi-extrusion-equipment-co-ltd/product-228054-2483057.html

[10] https://www.linkedin.com/posts/hsextruder_extruder-twinscrewextruder-extrudermanufacturer-activity-7205047110247858178-2FXe

[11] https://www.chinaplasonline.com/eMarketplace/exhibitorinfo/eng?compid=1034498&menu=service&Tab=products

[12] https://jieyatwinscrew.com/blog/guide-to-biodegradable-plastic-extruder/

[13] https://www.chinaplasonline.com/eMarketplace/exhibitorinfo/eng?compid=1034498&fromAd=hotpick

[14] https://www.haisiextrusion.com/aboutus.html

[15] https://www.kaironggroup.com/comparison-of-the-advantages-of-two-stage-extruders-and-twin-screw-extruders/

[16] https://www.haisiextrusion.com/news-p34.html

[17] https://www.chinaplasonline.com/eMarketplace/productinfo/eng?compid=1034498&SeqId=13042

[18] https://www.directindustry.com/prod/nanjing-haisi-extrusion-equipment-co-ltd/product-228054-2733169.html

[19] https://www.kaironggroup.com/how-to-choose-the-best-screw-extruder%EF%BC%9F/

[20] https://www.volza.com/company-profile/nanjing-haisi-extrusion-equipment-co-l-1159474