Content Menu

● Introduction

● Technical Specifications and Capabilities

>> Key Features

● Operational Excellence

>> Process Innovation

● Applications and Industries

● Technological Advantages

● Environmental Considerations

● Maintenance and Support

● Future Developments

● Frequently Asked Questions and Answers

>> Q1: What is the maximum extrusion force capability of a typical Danieli Breda Aluminum Extrusion Press?

>> Q2: How does the Energy Saving Solution (ESED 4.0) benefit operations?

>> Q3: What are the typical maintenance requirements for a Danieli Breda Aluminum Extrusion Press?

>> Q4: What types of aluminum profiles can be produced with this press?

>> Q5: What advanced features are included in the latest press automation systems?

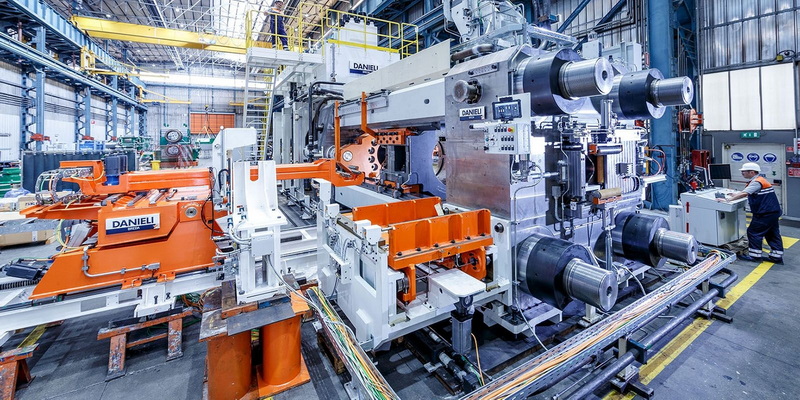

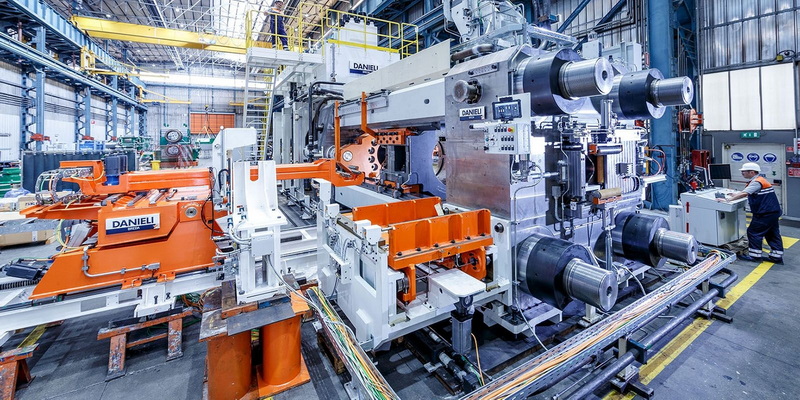

Introduction

The Danieli Breda Aluminum Extrusion Press represents the pinnacle of modern industrial engineering in the metal forming industry. This sophisticated piece of machinery has revolutionized the way manufacturers approach aluminum extrusion, offering unprecedented levels of efficiency, precision, and productivity.

Technical Specifications and Capabilities

The Danieli Breda Aluminum Extrusion Press comes in various configurations to meet different industrial needs. These systems are designed with cutting-edge technology that enables manufacturers to achieve optimal performance in aluminum extrusion processes.

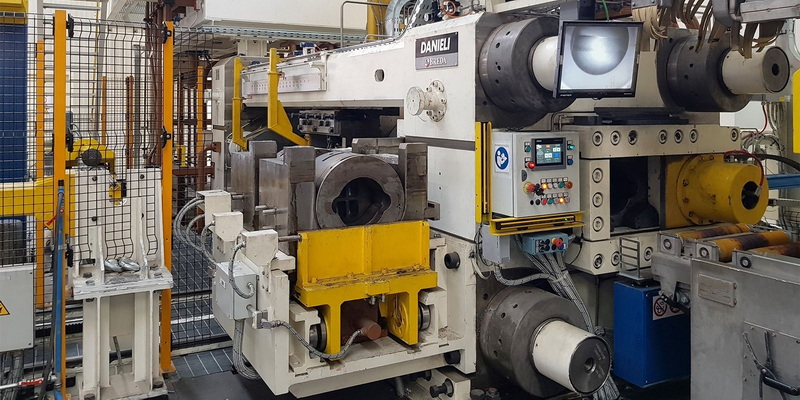

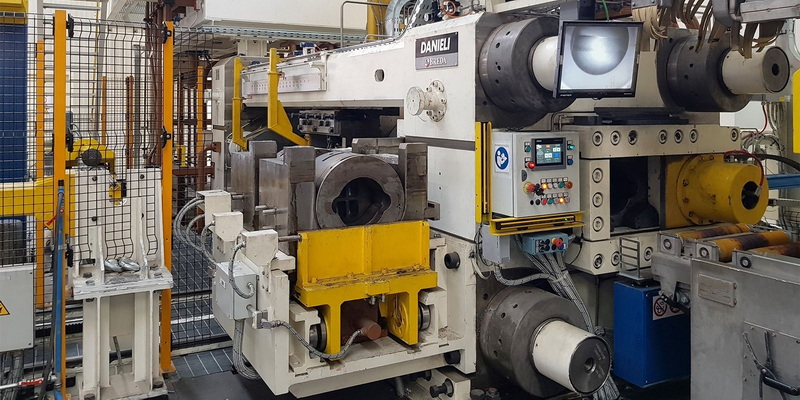

Key Features

- Advanced hydraulic systems

- Precision control mechanisms

- Energy-efficient operations

- Automated handling systems

- State-of-the-art safety features

- Integrated cooling systems

- Smart monitoring capabilities

Operational Excellence

The Danieli Breda Aluminum Extrusion Press incorporates sophisticated automation systems that ensure consistent quality and maximum productivity. The press's advanced control systems allow operators to maintain precise control over all aspects of the extrusion process.

Process Innovation

Modern Danieli Breda presses feature innovative technologies such as:

- Energy Saving Solution (ESED 4.0)

- Smart pressure control systems

- Advanced thermal management

- Integrated quality control systems

- Real-time monitoring capabilities

Applications and Industries

The versatility of the Danieli Breda Aluminum Extrusion Press makes it suitable for various industrial applications:

- Automotive components

- Construction materials

- Aerospace parts

- Consumer goods

- Industrial profiles

- Transportation equipment

- Architectural systems

Technological Advantages

The system's technological superiority is evident in several key areas:

- Reduced cycle times

- Enhanced product quality

- Improved energy efficiency

- Greater operational flexibility

- Advanced automation capabilities

- Reduced maintenance requirements

- Increased productivity

Environmental Considerations

Modern Danieli Breda Aluminum Extrusion Presses are designed with environmental sustainability in mind:

- Reduced energy consumption

- Minimized waste production

- Optimized resource utilization

- Eco-friendly hydraulic systems

- Sustainable manufacturing processes

Maintenance and Support

Regular maintenance ensures optimal performance and longevity:

- Preventive maintenance programs

- Technical support services

- Operator training

- Spare parts availability

- Remote diagnostics

- Performance optimization

- Regular system updates

Future Developments

The future of Danieli Breda Aluminum Extrusion Press technology continues to evolve:

- Integration of AI and machine learning

- Enhanced automation capabilities

- Improved energy efficiency

- Advanced materials processing

- Smart manufacturing integration

- Industry 4.0 compatibility

- Sustainable technology adoption

Frequently Asked Questions and Answers

Q1: What is the maximum extrusion force capability of a typical Danieli Breda Aluminum Extrusion Press?

A1: A typical Danieli Breda Aluminum Extrusion Press can achieve maximum extrusion forces ranging from 21.90MN to 40MN, depending on the model and configuration. The working pressure typically reaches up to 310 bar, ensuring optimal performance for various applications.

Q2: How does the Energy Saving Solution (ESED 4.0) benefit operations?

A2: The ESED 4.0 system provides significant energy savings of 25-30% compared to traditional systems. This innovative solution optimizes power consumption while maintaining high performance levels, resulting in reduced operational costs and improved sustainability.

Q3: What are the typical maintenance requirements for a Danieli Breda Aluminum Extrusion Press?

A3: Regular maintenance includes hydraulic system checks, alignment verification, wear component inspection, and control system updates. The frequency depends on usage intensity, but typically involves daily inspections, monthly preventive maintenance, and annual comprehensive servicing.

Q4: What types of aluminum profiles can be produced with this press?

A4: The press can produce a wide range of profiles including industrial profiles, architectural systems, automotive components, and specialized shapes. It can handle various billet sizes, typically ranging from 7 to 10 inches in diameter, allowing for diverse product applications.

Q5: What advanced features are included in the latest press automation systems?

A5: Modern automation systems include real-time monitoring capabilities, predictive maintenance algorithms, integrated quality control systems, smart pressure control, and Industry 4.0 connectivity features. These systems ensure optimal performance while minimizing operator intervention.