Content Menu

● Introduction

● Advantages of Aluminum Extrusion Materials

>> Strength and Rigidity

>> Lightweight Design

>> Easy Assembly and Disassembly

● Flexibility in Design

>> Customizable Structures

>> Adapting to Different Racing Equipment

>> Suitable for Different Heights and Body Types

● Building Your Own Aluminum Extrusion Sim Rig

>> Required Materials and Tools

>> Step-by-Step Guide: From Design to Assembly

>> Common Issues and Solutions

● Existing Options in the Market

>> Evaluating Different Brands and Models

>> Price-to-Performance Analysis

>> User Recommendations

● Conclusion

● Related Questions

>> 1. What are the key benefits of using aluminum extrusion in sim racing rigs?

>> 2. How can I customize my aluminum extrusion sim rig?

>> 3. What tools do I need to build my own sim rig?

>> 4. Are there pre-made aluminum extrusion sim rigs available?

>> 5. How do I ensure my sim rig is stable and does not wobble?

Introduction

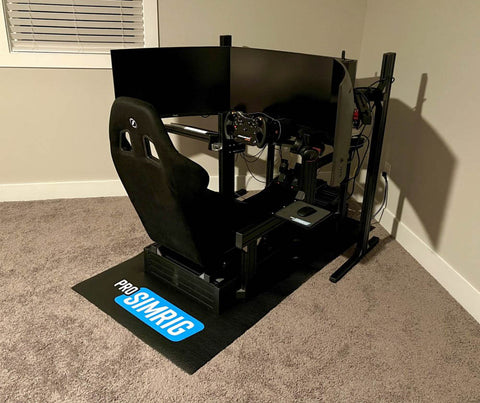

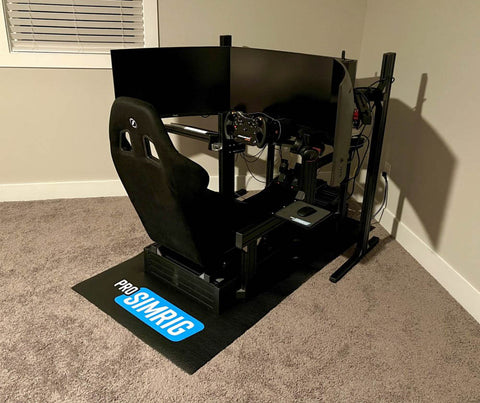

In recent years, sim racing has surged in popularity, attracting enthusiasts from all walks of life. As technology advances, the demand for high-quality racing simulators has increased, leading to the development of various setups that enhance the racing experience. One of the most significant innovations in this field is the use of 8020 aluminum profiles in sim racing rigs. These profiles offer a unique combination of strength, versatility, and ease of assembly, making them an ideal choice for both DIY enthusiasts and professional racers alike. In this article, we will explore the benefits of using 8020 aluminum profiles in sim racing setups, how to build your own rig, and the various options available on the market.

Advantages of Aluminum Extrusion Materials

Strength and Rigidity

One of the primary reasons why 8020 aluminum profiles are favored in sim racing setups is their exceptional strength and rigidity. Aluminum is known for its high strength-to-weight ratio, which means that it can support significant loads without adding excessive weight to the rig. This is particularly important in sim racing, where stability is crucial for an immersive experience. A sturdy rig minimizes vibrations and flexing, allowing for more accurate feedback from the racing equipment.

Lightweight Design

Another advantage of aluminum extrusion materials is their lightweight nature. Unlike steel or other heavier materials, aluminum profiles are easy to handle and transport. This is especially beneficial for sim racers who may need to move their rigs frequently, whether for competitions or simply to rearrange their gaming space. The lightweight design also contributes to the overall ease of assembly, making it accessible for users of all skill levels.

Easy Assembly and Disassembly

8020 aluminum profiles are designed for modularity, which means they can be easily assembled and disassembled without the need for specialized tools. This feature is particularly appealing to DIY enthusiasts who want to customize their rigs or make adjustments over time. The profiles come with pre-drilled holes, allowing users to connect them using simple fasteners. This ease of assembly not only saves time but also encourages creativity, as users can experiment with different configurations to find the perfect setup for their needs.

Flexibility in Design

Customizable Structures

One of the standout features of 8020 aluminum profiles is their flexibility in design. Users can create a wide range of configurations to suit their specific requirements. Whether you prefer a simple setup with a single monitor or a more complex arrangement with multiple screens and advanced racing peripherals, aluminum extrusion sim rigs can accommodate your vision. The ability to customize the structure means that you can tailor your rig to fit your space and personal preferences.

Adapting to Different Racing Equipment

Sim racing involves various equipment, including steering wheels, pedals, and seats. 8020 aluminum profiles can be easily adjusted to fit different types of racing gear. This adaptability ensures that your rig can evolve as your racing needs change. For instance, if you decide to upgrade your steering wheel or add a new set of pedals, you can modify your rig without having to start from scratch. This long-term flexibility is a significant advantage for serious sim racers.

Suitable for Different Heights and Body Types

Another benefit of using aluminum extrusion materials is their ability to accommodate users of different heights and body types. With adjustable components, you can create a rig that is comfortable and ergonomic for your specific needs. This is particularly important in sim racing, where comfort can significantly impact performance. A well-designed rig allows for proper posture and positioning, reducing fatigue during long racing sessions.

Building Your Own Aluminum Extrusion Sim Rig

Required Materials and Tools

Building your own aluminum extrusion sim rig can be a rewarding project. To get started, you will need the following materials and tools:

- 8020 Aluminum Profiles: Choose the appropriate lengths and sizes based on your design.

- Fasteners: T-nuts and bolts to connect the profiles securely.

- Racing Seat: A comfortable seat that fits your rig design.

- Steering Wheel and Pedals: Select the equipment that suits your racing style.

- Tools: A basic toolkit including an Allen wrench, screwdriver, and measuring tape.

Step-by-Step Guide: From Design to Assembly

1. Design Your Rig: Start by sketching your desired setup. Consider the dimensions of your space and the equipment you plan to use. There are many online resources and communities where you can find inspiration and design ideas.

2. Cut the Aluminum Profiles: Based on your design, cut the aluminum profiles to the required lengths. Many suppliers offer cutting services, or you can use a saw designed for aluminum.

3. Assemble the Frame: Begin by assembling the base of your rig. Use T-nuts and bolts to connect the profiles securely. Ensure that the frame is level and stable.

4. Attach the Seat: Once the frame is complete, attach your racing seat. Make sure it is positioned at a comfortable height and angle for optimal driving posture.

5. Install the Steering Wheel and Pedals: Securely mount your steering wheel and pedals to the rig. Adjust their positions to suit your driving style.

6. Test and Adjust: After assembly, test your rig to ensure everything is functioning correctly. Make any necessary adjustments to improve comfort and performance.

Common Issues and Solutions

While building your own aluminum extrusion sim rig can be straightforward, you may encounter some common issues. Here are a few potential problems and their solutions:

- Flexing or Wobbling: If your rig feels unstable, check the connections between the profiles. Tighten any loose bolts and consider adding additional support brackets.

- Inadequate Space: If you find that your rig is too cramped, consider redesigning it to allow for more space. You can also adjust the height of the seat or the angle of the steering wheel.

- Equipment Compatibility: Ensure that your racing gear is compatible with your rig design. If you encounter issues, look for adjustable mounts or adapters that can help.

Existing Options in the Market

Evaluating Different Brands and Models

If building your own rig seems daunting, there are many pre-made options available on the market. Various brands offer aluminum extrusion sim rigs that cater to different budgets and preferences. When evaluating these options, consider the following factors:

- Build Quality: Look for rigs made from high-quality aluminum profiles that offer durability and stability.

- Adjustability: Ensure that the rig allows for adjustments to accommodate different users and equipment.

- User Reviews: Read customer reviews to gauge the performance and reliability of the rig.

Price-to-Performance Analysis

When choosing a pre-made rig, it's essential to consider the price-to-performance ratio. Some rigs may be more expensive due to brand reputation or additional features, but they may not necessarily offer better performance. Compare different models and assess whether the features justify the price.

User Recommendations

Engaging with the sim racing community can provide valuable insights into the best rigs available. Online forums, social media groups, and YouTube channels often feature reviews and recommendations from experienced users. These resources can help you make an informed decision when selecting a rig that meets your needs.

Conclusion

In conclusion, 8020 aluminum profiles are an excellent choice for sim racing setups due to their strength, lightweight design, and flexibility. Whether you choose to build your own aluminum extrusion sim rig or purchase a pre-made option, the benefits of using aluminum profiles are clear. They offer a customizable and ergonomic solution that enhances the overall racing experience. As the world of sim racing continues to evolve, investing in a quality rig will undoubtedly improve your performance and enjoyment on the virtual track.

Related Questions

1. What are the key benefits of using aluminum extrusion in sim racing rigs?

Aluminum extrusion provides strength, lightweight design, and ease of assembly, making it ideal for creating stable and customizable sim racing setups.

2. How can I customize my aluminum extrusion sim rig?

You can customize your rig by adjusting the height, angle, and position of components like the seat, steering wheel, and pedals to suit your preferences and comfort.

3. What tools do I need to build my own sim rig?

Basic tools such as an Allen wrench, screwdriver, measuring tape, and a saw for cutting aluminum profiles are typically required to build your own sim rig.

4. Are there pre-made aluminum extrusion sim rigs available?

Yes, many brands offer pre-made aluminum extrusion sim rigs that cater to various budgets and preferences, providing a convenient option for those who prefer not to build their own.

5. How do I ensure my sim rig is stable and does not wobble?

To ensure stability, check that all connections are tight, use high-quality aluminum profiles, and consider adding support brackets if necessary.