Content Menu

● Understanding Aluminum Extrusions

>> The 2020 Aluminum Extrusion Profile

● Weight of 2020 Aluminum Extrusion

>> Volume Calculation

● Applications of 2020 Aluminum Extrusions

● Benefits of Using 2020 Aluminum Extrusions

● Videos on 2020 Aluminum Extrusions

● Factors Affecting the Weight of 2020 Aluminum Extrusions

● Maintenance and Care for Aluminum Extrusions

● Conclusion

● Frequently Asked Questions

>> 1. What is the standard length of a 2020 aluminum extrusion?

>> 2. Can 2020 aluminum extrusions be welded?

>> 3. What tools are needed to assemble 2020 aluminum extrusions?

>> 4. Are there different alloys used for 2020 aluminum extrusions?

>> 5. How do I calculate the weight of a different length of 2020 aluminum extrusion?

Aluminum extrusions are widely used in various industries due to their lightweight, strength, and versatility. Among the many profiles available, the 2020 aluminum extrusion is particularly popular for its compact size and robust design. This article will explore the weight of a 2020 aluminum extrusion, its applications, benefits, and how to calculate its weight. We will also provide visual aids and videos to enhance understanding.

Understanding Aluminum Extrusions

Aluminum extrusion is a process that involves shaping aluminum alloy into a desired cross-sectional profile. This is achieved by forcing the aluminum through a die, which gives it the desired shape. The resulting extrusions can be used in a variety of applications, from structural components to decorative elements.

The 2020 Aluminum Extrusion Profile

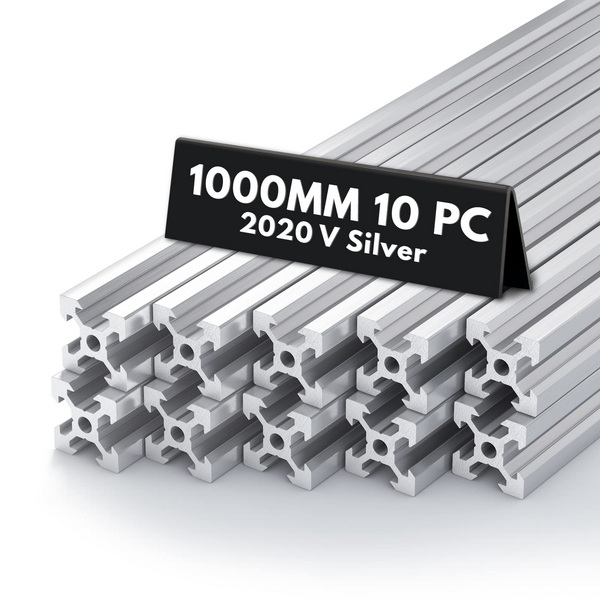

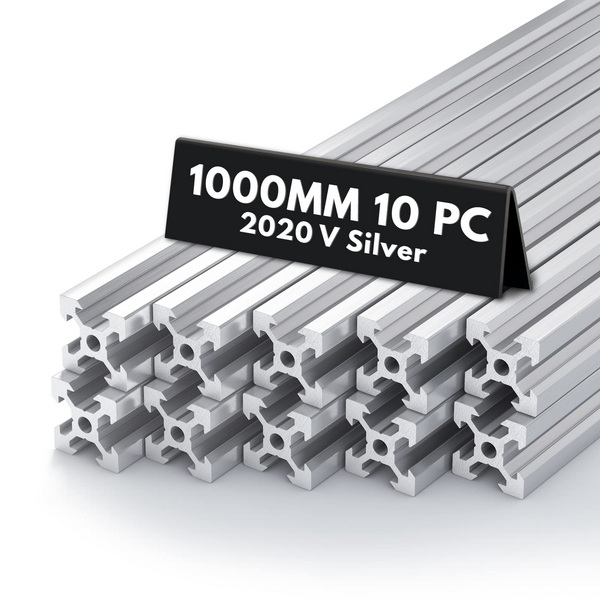

The 2020 aluminum extrusion profile measures 20mm x 20mm, making it a part of the 20 Series of T-slot aluminum extrusions. This profile features four open T-slots on each side, allowing for easy assembly and integration with other components. The 2020 profile is commonly used in modular construction, automation, and framing systems.

Weight of 2020 Aluminum Extrusion

The weight of a 2020 aluminum extrusion can vary based on its length and the specific alloy used. Generally, the density of aluminum is approximately 2.7 grams per cubic centimeter. To calculate the weight of a 2020 aluminum extrusion, you can use the following formula:

Weight (kg) = Volume (cm³) × Density (g/cm³) / 1000

Volume Calculation

The volume of the 2020 aluminum extrusion can be calculated by determining its cross-sectional area and multiplying it by its length. The cross-sectional area of the 2020 profile can be calculated as follows:

- Cross-sectional area = Width × Height

- Cross-sectional area = 20mm × 20mm = 400mm² = 40cm²

If you have a length of, for example, 1000mm (or 100cm), the volume would be:

- Volume = Cross-sectional area × Length

- Volume = 40cm² × 100cm = 4000cm³

Now, using the density of aluminum:

- Weight = 4000cm³ × 2.7g/cm³ / 1000 = 10.8kg

Thus, a 1000mm long 2020 aluminum extrusion weighs approximately 10.8 kilograms.

Applications of 2020 Aluminum Extrusions

The 2020 aluminum extrusion is used in various applications due to its strength and versatility. Some common uses include:

1. Modular Framing Systems: The 2020 profile is ideal for creating modular frames for workstations, enclosures, and machinery.

2. Automation Equipment: Many automation systems utilize 2020 extrusions for their lightweight and strong structural properties.

3. DIY Projects: Hobbyists and DIY enthusiasts often use 2020 aluminum extrusions for building custom projects, such as 3D printer frames and robotics.

4. Furniture Design: The sleek design of the 2020 profile makes it suitable for modern furniture applications, including desks and shelving units.

5. Display and Exhibit Structures: The 2020 aluminum extrusion is often used in trade shows and exhibitions to create lightweight yet sturdy display structures.

Benefits of Using 2020 Aluminum Extrusions

There are several advantages to using 2020 aluminum extrusions in various projects:

- Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps prevent corrosion.

- Ease of Assembly: The T-slot design allows for quick and easy assembly without the need for welding or special tools.

- Versatility: The 2020 profile can be easily integrated with other components, making it suitable for a wide range of applications.

- Cost-Effectiveness: Compared to other materials, aluminum extrusions can be more cost-effective in terms of both material and labor costs, especially for large-scale projects.

Videos on 2020 Aluminum Extrusions

To further enhance your understanding of 2020 aluminum extrusions, here are some informative videos:

1. [2020 Aluminum Extrusion Explained](https://www.youtube.com/watch?v=IcVu7G71N50)

This video provides a comprehensive overview of the 2020 aluminum extrusion, including its properties and applications.

2. [8020 MASTER CLASS - Deep Dive: How to Use 8020 Extruded Aluminum](https://www.youtube.com/watch?v=AKssPWSYZwg)

This master class dives deep into the use of 8020 extruded aluminum, which includes the 2020 profile.

3. [Extrusion Strength Test](https://www.youtube.com/watch?v=k99Vb7uBiUw)

This video tests the strength of various aluminum extrusions, including the 2020 profile.

Factors Affecting the Weight of 2020 Aluminum Extrusions

While the basic calculation for the weight of a 2020 aluminum extrusion is straightforward, several factors can influence the actual weight:

- Length of the Extrusion: As demonstrated in the calculations, the length directly affects the volume and, consequently, the weight.

- Alloy Composition: Different aluminum alloys have varying densities. For example, 6061 aluminum has a slightly different density compared to 6063, which is commonly used for extrusions.

- Surface Treatments: Anodizing or other surface treatments can add a small amount of weight, although this is generally negligible compared to the overall weight of the extrusion.

Maintenance and Care for Aluminum Extrusions

To ensure the longevity and performance of 2020 aluminum extrusions, proper maintenance is essential:

- Regular Cleaning: Dust and debris can accumulate on the surface, so regular cleaning with mild soap and water is recommended.

- Inspect for Damage: Periodically check for any signs of wear or damage, especially in high-stress applications.

- Avoid Harsh Chemicals: When cleaning, avoid using harsh chemicals that can damage the protective oxide layer.

Conclusion

In summary, the weight of a 2020 aluminum extrusion is influenced by its length and the specific alloy used. With a density of approximately 2.7 grams per cubic centimeter, a 1000mm long 2020 aluminum extrusion weighs around 10.8 kilograms. This profile is widely used in various applications due to its lightweight, strength, and ease of assembly. The versatility of the 2020 aluminum extrusion makes it a popular choice for both industrial and DIY projects.

Frequently Asked Questions

1. What is the standard length of a 2020 aluminum extrusion?

Standard lengths for 2020 aluminum extrusions typically range from 1 meter to 6 meters, but custom lengths can also be ordered.

2. Can 2020 aluminum extrusions be welded?

While aluminum can be welded, it is generally not recommended for T-slot profiles like the 2020 due to the potential for warping and the need for specialized equipment.

3. What tools are needed to assemble 2020 aluminum extrusions?

Basic tools such as an Allen wrench, a saw for cutting, and a measuring tape are typically sufficient for assembly.

4. Are there different alloys used for 2020 aluminum extrusions?

Yes, various aluminum alloys can be used for extrusions, with 6063 and 6061 being the most common due to their excellent mechanical properties.

5. How do I calculate the weight of a different length of 2020 aluminum extrusion?

Use the formula: Weight (kg) = Volume (cm³) × Density (g/cm³) / 1000, adjusting the length in the volume calculation accordingly.