Content Menu

● Understanding 1515 Aluminum Extrusions

>> Material Properties

>> Weight Capacity

● Applications of 1515 Aluminum Extrusions

● Factors Influencing Weight Capacity

>> Length of the Extrusion

>> Load Type

>> Support Method

>> Environmental Factors

● Design Considerations

● Conclusion

● Related Questions

>> 1. What are the typical material properties of 1515 aluminum extrusions?

>> 2. How do different support methods affect the weight capacity of 1515 extrusions?

>> 3. Are there any specific design guidelines for using 1515 extrusions in outdoor environments?

>> 4. Can 1515 aluminum extrusions be used in high-temperature applications?

>> 5. What is the best way to connect 1515 aluminum extrusions?

Aluminum extrusions are widely used in various industries due to their lightweight, strength, and versatility. Among the many profiles available, the 1515 aluminum extrusion is particularly popular. This article will explore the weight capacity of 1515 aluminum extrusions, their applications, and factors that influence their load-bearing capabilities.

Understanding 1515 Aluminum Extrusions

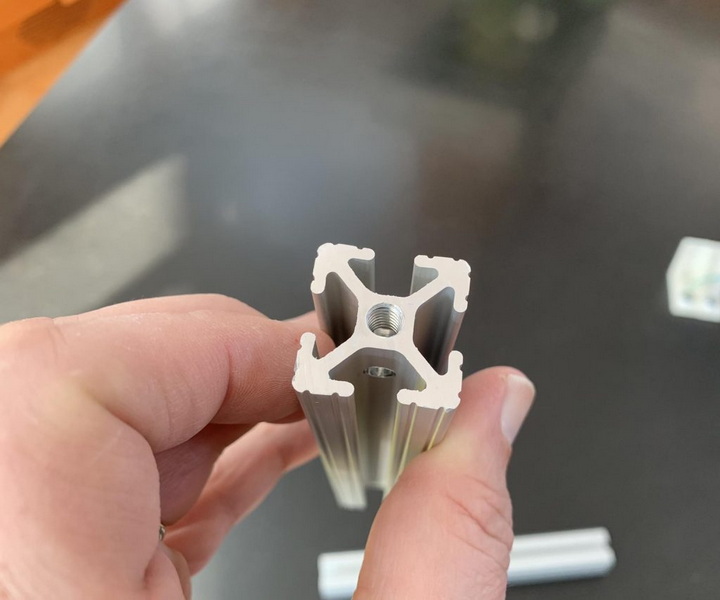

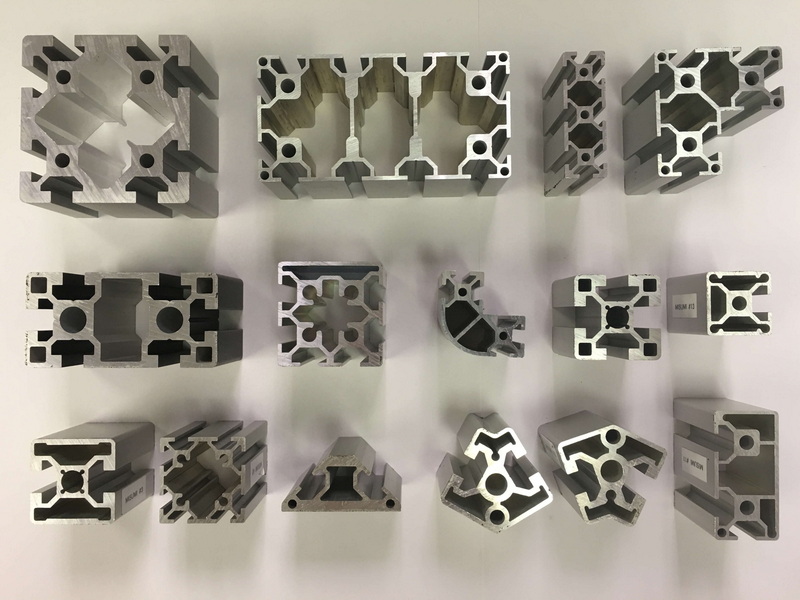

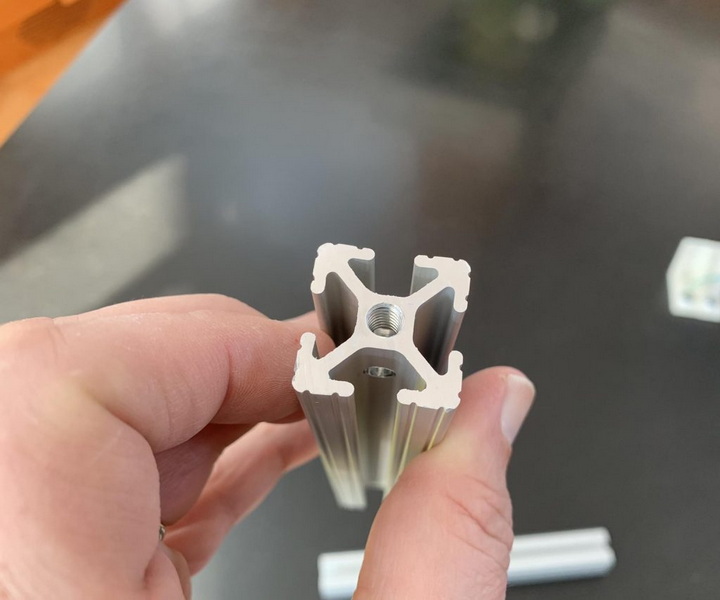

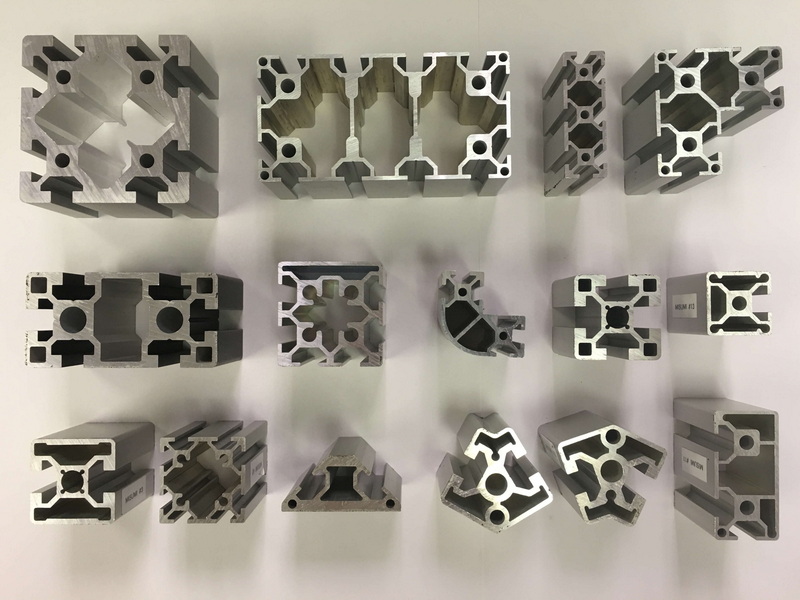

The term "1515" refers to the dimensions of the aluminum extrusion, specifically 1.5 inches by 1.5 inches. This square profile is part of the 15-series of aluminum extrusions, which are characterized by their modular design. The 1515 extrusion is often used in framing applications, such as in the construction of workstations, machine guards, and other structural frameworks.

Material Properties

Aluminum is known for its excellent strength-to-weight ratio. The 1515 aluminum extrusion is typically made from 6063 aluminum alloy, which is known for its good corrosion resistance and medium strength. The yield strength of 6063 aluminum is approximately 240 MPa (35,000 psi), making it suitable for various structural applications.

Weight Capacity

The weight capacity of a 1515 aluminum extrusion depends on several factors, including the length of the extrusion, the type of load (static or dynamic), and the method of support. Generally, the weight capacity can be calculated using engineering principles that consider the moment of inertia and the modulus of elasticity of the material.

For example, a 1515 extrusion supported at both ends can typically support a distributed load of around 100 to 200 pounds per linear foot, depending on the specific application and design considerations. However, it is crucial to consult engineering guidelines or perform calculations for specific applications to ensure safety and reliability.

Applications of 1515 Aluminum Extrusions

1515 aluminum extrusions are used in a variety of applications due to their strength and versatility. Some common uses include:

- Workstations: The modular nature of 1515 extrusions allows for the easy construction of custom workstations that can be adapted to various tasks.

- Machine Guards: These extrusions can be used to create protective barriers around machinery, ensuring safety in industrial environments.

- Display Frames: The aesthetic appeal of aluminum makes it a popular choice for display frames in retail and exhibition settings.

- Automated Systems: In robotics and automation, 1515 extrusions are often used to build frames for robotic arms and other automated equipment.

Factors Influencing Weight Capacity

Several factors can influence the weight capacity of 1515 aluminum extrusions:

Length of the Extrusion

The longer the extrusion, the lower its weight capacity due to increased bending moments. Shorter lengths can support more weight, while longer spans may require additional support or bracing.

Load Type

Static loads (constant weight) are easier to manage than dynamic loads (moving weight). Dynamic loads can introduce additional forces that may reduce the effective weight capacity of the extrusion.

Support Method

The way the extrusion is supported significantly affects its load-bearing capabilities. For instance, an extrusion supported at both ends will have a different weight capacity than one that is cantilevered (supported at one end).

Environmental Factors

Environmental conditions, such as temperature and humidity, can also affect the performance of aluminum extrusions. For example, extreme temperatures can alter the material properties, potentially impacting weight capacity.

Design Considerations

When designing structures using 1515 aluminum extrusions, several considerations should be taken into account:

- Bracing: Adding diagonal bracing can significantly increase the stability and weight capacity of the structure.

- Connection Methods: The choice of connectors (such as bolts, screws, or welding) can impact the overall strength of the assembly.

- Load Distribution: Ensuring that loads are evenly distributed across the extrusion can help prevent localized failures.

Conclusion

The 1515 aluminum extrusion is a versatile and strong option for various structural applications. Understanding its weight capacity and the factors that influence it is crucial for ensuring safety and effectiveness in design. By considering the material properties, load types, and design guidelines, engineers and designers can effectively utilize 1515 extrusions in their projects.

Related Questions

1. What are the typical material properties of 1515 aluminum extrusions?

The 1515 aluminum extrusion is typically made from 6063 aluminum alloy, known for its good corrosion resistance and medium strength, with a yield strength of approximately 240 MPa (35,000 psi).

2. How do different support methods affect the weight capacity of 1515 extrusions?

The weight capacity varies based on support methods; for example, an extrusion supported at both ends can support more weight than one that is cantilevered.

3. Are there any specific design guidelines for using 1515 extrusions in outdoor environments?

When using 1515 extrusions outdoors, consider factors like corrosion resistance, UV exposure, and temperature fluctuations, and use appropriate coatings or treatments to enhance durability.

4. Can 1515 aluminum extrusions be used in high-temperature applications?

While aluminum has good thermal conductivity, its strength can decrease at elevated temperatures. For high-temperature applications, consult material specifications and consider using alloys designed for such conditions.

5. What is the best way to connect 1515 aluminum extrusions?

Common connection methods include using T-nuts and bolts, which allow for easy assembly and disassembly, or welding for permanent structures. The choice depends on the application and required strength.

This article provides a comprehensive overview of the weight capacity of 1515 aluminum extrusions, their applications, and important design considerations. By understanding these factors, users can effectively utilize these extrusions in various projects.